Phase I /1902 C&S Coals

1 ...

345678910

1 ...

345678910

Re: Phase "Zero" / St Charles Coal Cars

|

Outstanding work, John!

|

Re: Phase "Zero" / St Charles Coal Cars

|

In reply to this post by Jim Courtney

Keith and Jim,

I'm thinking more about the coal car tiedown rods, and I have an idea to make a die to forge flattened wire ones like the ones I made, but much quicker and more accurately. If I can work this out, would you be interested in some S scale rod sets? If so, could you tell me what diameter wire you would want, how long they should be overall, and how thick your side boards are? I can't promise anything, but I'd like to give it a try. Cheers, John

John Greenly

Lansing, NY |

Re: Phase "Zero" / St Charles Coal Cars

|

This post was updated on .

Thats a very gracious offer, John!

I'd be interested if this works out. But I would insist on paying you for your time. According to Derrell Poole's drawings, the tie-rods themselves were about 1" in diameter. The flattened strap part was about 2" wide. The strap inside and outside the car wrapped around the top side board with about 4" on each side, below the top of the board, secured with the single bolt. In S scale, the rod would be about 0.015" in diameter, the width of the flattened strap about 0.030". I made a few compromises making sure that Mike's Shapeways printed stakes would fit properly, using a Berlyn / PVC coal car floor and underframe. My side boards are 0.030" thick, just a smidge under 2 scale inches. The total height of the 4 side boards (top of floor to top of uppermost side board) is 0.630". Mounting holes in the floor are 0.030" deep (before hitting the sheet metal weight), so overall height to top edge of side should be at least 0.650". The strap part of the tie rod should hang over the top side board about 0.060" (~4 scale inches), inside and out. If you can devise a way to mass produce these, I could use enough for 5 cars (60) plus a few spares for screw-ups. Keith may have used slightly different width/thickness of styrene for the side boards, don't know about this. (An S-scale 2x10 is 0.0312" x 0.1563"--I used 0.030" x 0.156" Evergreen strip stock. This would be a handy part to have in any scale. They were used on both the St Charles and 1902 coal cars. Jim

Jim Courtney

Poulsbo, WA |

|

In reply to this post by John Greenly

John,

Sounds good ,if possible I would like enough for2or 3 cars. Paul R. |

Re: Phase "Zero" / St Charles Coal Cars

|

In reply to this post by Jim Courtney

John, very nice work, especially for HOn3. Very cool.

I also would be in for 4 cars worth, plus a couple spares, using Jim's specs. If this little project is getting out of hand though you can skip me, I'm still a ways away from completing mine anyway... Keith and Jim, glad the 3D stakes worked out. I've at least assembled the side boards with stakes but am rethinking the frame and deck. Hope to see you guys in Denver... Mike McKenzie Frankfort IL |

Re: Phase "Zero" / St Charles Coal Cars

|

How about just using common white paper for the top flat part. It is about .005 thick, bends well and can be embossed with the bolt heads if desired. It is also uncommonly inexpensive and easy to cut with an Xacto knife, razor blade or even fine shears. it can be attached with ACC and that will also soak in and stiffen it and then it can be colored with paint, markers or even pastel pencils. The rod can be wire or plastic rod or if you are really cheap stretched plastic sprue.

Best, Todd Ferguson |

Re: Phase "Zero" / St Charles Coal Cars

|

Well, reading this got me experimenting a little. I have a good pair of Lineman's Pliers and those have a nice flat section out near the tip that can do a pretty decent job of flattening out a piece of wire up to about .020". Well that was the largest I just tested. I also have a Pano Vise with smooth steel jaws and that also does a dandy job of flattening and it would be easy enough to jig it to make the flats a constant length too. It or another vice with a flat jaw would probably flatten even larger wire. But I still like the paper idea too...

I would also think about filing out a small brass piece to make the bends repeat the same each time and you could probably crank these out pretty fast from wire. If done using the vice and a bending jig I bet they could be made in 30 seconds or less each. Best, Todd Ferguson |

|

Would it help if you first heated the brass to make it easier to work?

dave |

Re: Phase "Zero" / St Charles Coal Cars

|

In reply to this post by John Greenly

Darnit, John Greenly!

Keith Hayes

Leadville in Sn3 |

Re: Phase "Zero" / St Charles Coal Cars

|

Are you planning on having the corresponding Nut/Boltshanks protruding under the sidesill?

UpSideDownC

in New Zealand |

Re: Phase "Zero" / St Charles Coal Cars

|

In reply to this post by Keith Hayes

Hi Keith,

looks like your guys are making a good effort, maybe they don't need me! But in case they do, let me give you an update. I did some experiments over the weekend. It looks like it works best to flatten and emboss the end of the wire at once with a single die. I intend to make a final production die tomorrow, I got the steel today. Do the dimensions Jim gave suit you too? I'll post results here, and if they look good I'll send some for your crew to try out. Chris, yes, I will do that on my car, when the mood strikes me…. Cheers, John

John Greenly

Lansing, NY |

Re: Phase "Zero" / St Charles Coal Cars

|

This post was updated on .

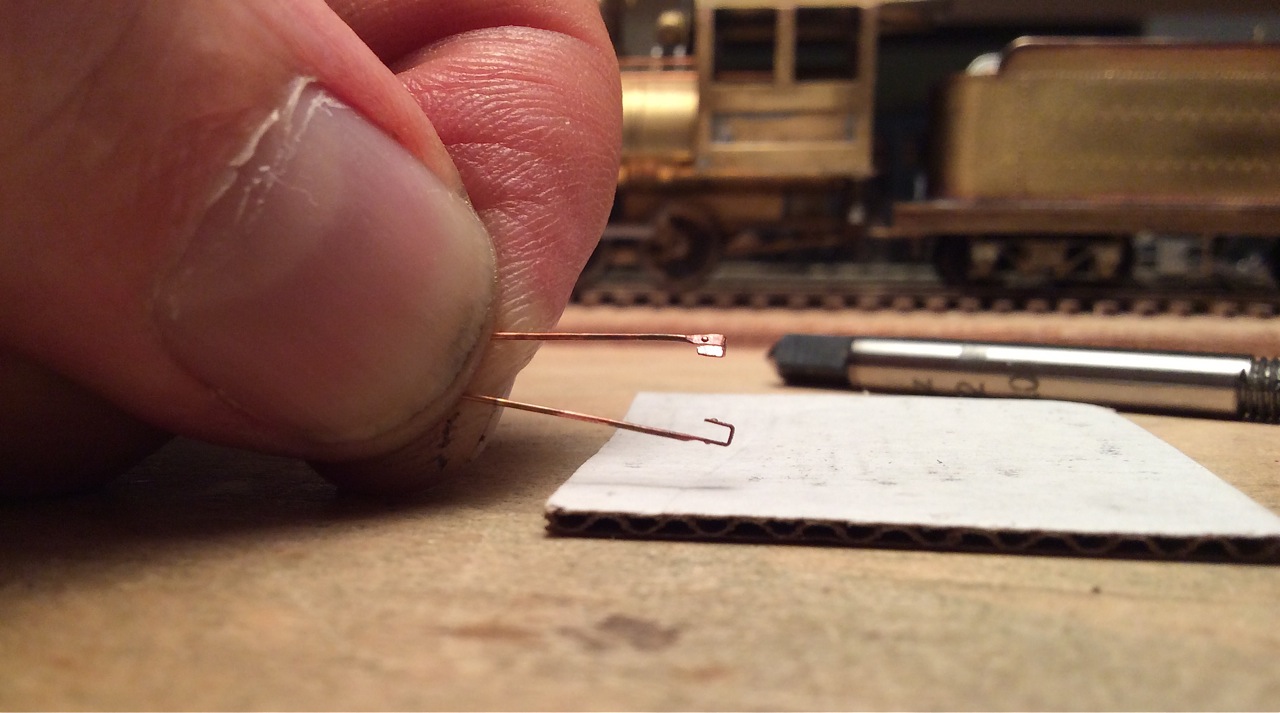

Okay, I got inspired, and made a die tonight. Couldn't let Keith's S-scale crew beat me to the punch!

Here are the first two "production" rods:  These are close to Jim's specs for S scale, .015'" wire, the flat part is .006" thick, and tends to come out a little under .030" wide at the moment, but I think that is fixable. I need to work out a couple of things to be able to turn them out quicker. These certainly did not appear in 30 seconds, but they are already substantially quicker, more accurate and less stress on the production staff (that's me-- I haven't managed to train HO scale people the way Keith has in S scale, maybe being larger they have more brain cells) than the set I made for my coal car. I think using an arbor press in my lab instead of what I have at home will be easier to handle, and I need to make a guide to locate the wire correctly in position in the die. The bending goes pretty quick, I ground the tip of one jaw of an old pair of needle-nose pliers to exactly .030" wide to hold the middle of the flat between the two bends. As you can see, the rods are made so that the round wire is flush to the flat facing the board, so it will sit flush against the board. I don't know for sure whether the real ones were like that, but I think they were-- look closely at the photo on p.67 of NG Pict VIII. You can see that the real ones weren't all totally accurately bent, and of course they, and the boards, got beat up badly over time, so the fit wasn't always tight. For now, bedtime! Cheers, John

John Greenly

Lansing, NY |

Re: Phase "Zero" / St Charles Coal Cars

|

They look incredible John, very nice.

Mike |

Re: Phase "Zero" / St Charles Coal Cars

|

In reply to this post by John Greenly

Incredible, John. I hereby nominate you for C&S blacksmithing god!

Jim Courtney

Poulsbo, WA |

Re: Phase "Zero" / St Charles Coal Cars

|

In reply to this post by Keith Hayes

Keith,

Your photo implies that you're trying out my proposed method of using the foil from the top of a wine bottle, to fabricate the upper parts of the side board brackets. Did you drink the bottle of wine before or after you began fabricating the parts? I prefer the former, as it gives me more confidence in cutting and bending.

Jim Courtney

Poulsbo, WA |

Re: Phase "Zero" / St Charles Coal Cars

|

In reply to this post by Jim Courtney

Wow, thanks, I can't wait to tell my son! He's a professional blacksmith- actually a bladesmith, makes knives, historical sword reproductions and such, with consummate skill. I have a few tweaks to make before I'm ready to go into real production. I need to order some .004" shim stock to make the stamping work just right. I'm wondering how the rods looked in use. As you see, they turn reddish from the annealing, but the ones I made last night I just annealed the top end so as to leave the rest stiffer. So, were the rods painted, or just left bare? I would suspect that paint wouldn't last long in any case. A good option for finishing them might be chemical blackening. I like a blackener called Jax Pewter Black, which makes brass not pure black, but more dark greyish like bare wrought iron. That might be the right sort of finish for the tiedown rods. Any opinions? John

John Greenly

Lansing, NY |

Re: Phase "Zero" / St Charles Coal Cars

|

Nice work, Keith and John!

This Morrison Smith image is the best colour shot I've found:  (Silica Branch scrapping; 1941) Cheers, Jeff. |

Re: Phase "Zero" / St Charles Coal Cars

|

In reply to this post by Jim Courtney

Phase I, II and III in a row!

Yes, I used the Courtney technique, except I drank the wine the night before, then cut, fabricated and applied the parts the next day. Steadier hands that way.

Keith Hayes

Leadville in Sn3 |

Re: Phase "Zero" / St Charles Coal Cars

|

In reply to this post by John Greenly

Rusty.

My money is that the interiors did not get painted, and if they did, only the steel got the paint. Seems like this would wear off in service quickly, and rust when exposed to wet aggregates.

Keith Hayes

Leadville in Sn3 |

Re: Phase "Zero" / St Charles Coal Cars

|

This post was updated on .

Yup. that makes sense to me. Also, in Jeff's photo the rods and inside corner irons don't show any sign of paint that I can see. Keith, your coal cars look superb, and so does the whole scene! I especially like the faded phase 2 car. Someday I hope to have those three cars in a row too. I have my phase 1 car and a nice phase 3 Grandt kit that I put together, but my phase 2 is presently no more than a pair of Bettendorf trucks waiting for a load. Cheers, John

John Greenly

Lansing, NY |

«

Return to C&Sng Discussion Forum

|

1 view|%1 views

| Free forum by Nabble | Edit this page |