a new (old) #59?

1234567

1234567

|

This post was updated on .

See John's long update at the bottom of the previous page.

Hey John, As for headlight, you might consider one of the CB&Q style headlights as on C&S 69. Weissman markets an HOn3 version in their eBay store: https://www.ebay.com/itm/HO-HOn3-BRASS-WISEMAN-BACK-SHOP-PART-HBS180-STEAM-LOCOMOTIVE-BOX-HEADLIGHT/152618610908?hash=item2388c730dc:g:wYEAAOSw4A5Y0VYC   These came in common use during the mid teens and early twenties. Many had a little vent on top (not present on the headlight of number 69). Rhode Islands that used this headlight at one time or another included numbers 58 and 62. Maybe 59 had one for a while and never got photographed (he rationalizes). In S scale, I have used the coach vents from Tomalco for that detail. There is a brass set offered, also on eBay: https://www.ebay.com/itm/BRASS-PASSENGER-CAR-ROOF-DETAIL-HOn3-Model-Railroad-Lost-Wax-Detail-TCP3011/362190767043?_trkparms=aid%3D111001%26algo%3DREC.SEED%26ao%3D1%26asc%3D41375%26meid%3Dec21c569df67468684ea00bcafad3a67%26pid%3D100033%26rk%3D2%26rkt%3D8%26sd%3D152618610908&_trksid=p2045573.c100033.m2042 I don't know how well these parts will scale out in HOn3. No suggestions as to stack base, however. My S scale Overland locomotives with plows had a chain mounted to the top of the smoke box front, traveled down through the rear opening of coupler pocket, back up through the front opening of the coupler pocket, attaching to the same mount at top of smoke box. A short piece of rod with turnbuckle was interposed in the middle of both the front and rear chain, to tighten things up. I'm in the hospital, working today. if Chris doesn't beat me to it, I'll try to post some photos of the box headlight and plows with chains in the next couple of days when I get home to my computer. Jim

Jim Courtney

Poulsbo, WA |

|

In reply to this post by John Greenly

Lots of detail?? Not at all. Thanks for including all your details! It's exactly the thing to get all the juices flowing so to speak. This is the headlight that I used on my #13. As you say, I couldn't find any published dimensions for something as mundane as a headlight, but using dividers and perspective on lots of photos, this headlight seems to be very close. Some of the locos in that time period had a similar headlight with angled number boards on the top and that also seem to be just a little deeper front to back. For a locomotive without the angled number boards, this casting seems about right. The final proof in the pudding is that it "looks kind-of right" on the finished engine. You might peek back a few pages in the forum to my B3A post and you can see the casting on another locomotive for comparison. Please keep the pictures and details coming. I love seeing what you are doing here! Skip Egdorf Los Alamos, NM

Skip Egdorf

|

|

Administrator

|

In reply to this post by Jim Courtney

I agree 100% that the box headlight from Wiseman would be perfect. PSC offers a similar headlight in O Scale that first appeared on their #69 And later their #58. This one, which may have been a Back Shop casting is much more correct as it is dimensionally square. I have had to perform Dremel surgery on all the PSC castings I have used. This style box headlight was very common on C&S locomotives for many years. #72 lost one just like this in the Como Roundhouse fire, and my #69 has the other of the two in my roster. The other style like the one carried by #22 in later years would also be A-OK. Both of those headlight styles were modified to electric from oil. You couldn't go wrong with either

|

|

In reply to this post by John Greenly

I've looked at many photos of plows, but so far I haven't found one that shows the inside of the plow and these attachments.

Not many good photos of the inside of the plow, but here is one of C&S 8, caught with its plow down:  R.V. Nixon photo, Denver, 1933. Looks like a possible Viagra overdose!  No details of the inside of the plow itself, but a good view of the attachment to pilot beam and lead truck flanger blades. Note the good size chains, mounted to the bottom of the smoke box, through holes in the pilot deck, that attached to the bottom of the plow. I'll keep looking . . .

Jim Courtney

Poulsbo, WA |

|

In reply to this post by skip

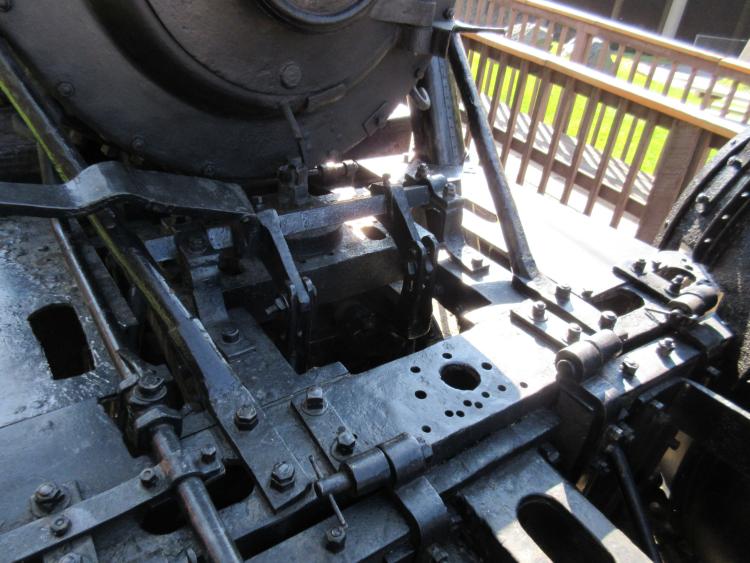

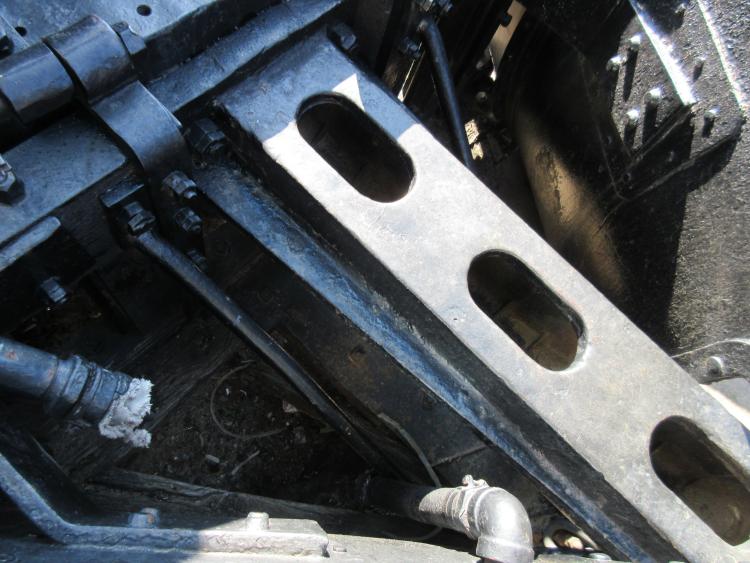

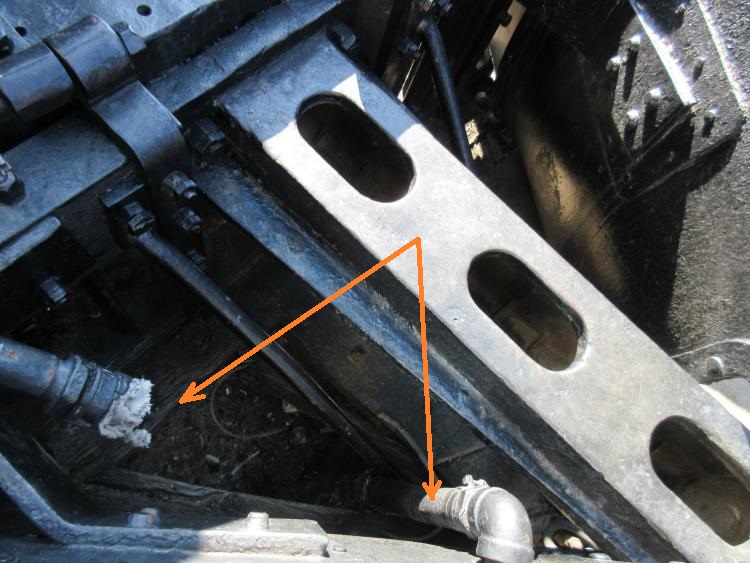

Thanks Jim, that photo helps with the lower chains. Here are the only photos I've found of the inside of a plow, two that Doug Heitkamp posted on the "60 details" thread. I'll take the liberty of reposting them here, thanks Doug:

I'm confused. The plow attachment to the pilot beam is by means of hinges, so the plow would be able to pivot upward. But looking at many photos of these plows, the fit of the ends of the pilot beam through the holes in the plow look much too close to allow the plow to be raised. It doesn't look possible to clear the ends of the pilot beam by pivoting upward. And also, in this second photo here it looks like the long coupler pocket is bolted rigidly to the pilot beam, so the plow would not be able to be raised without removing the pocket. Is this true or am I not seeing it right? It looks like the chains to the smokebox top are taking the weight of the plow, and have turnbuckles to adjust that. The chains going to the bottom corners of the plow must be to hold it back tight against the pilot beam? Thanks also to Jim and Mike for the headlight info. All the photos I have of #59 show either the early arc light with the flat front-facing number board in front of the vent (1905 at Pitkin photo) or the Handlan-Buck light with the wedge number board on top (1923-24 photos). (This information from Jim, thanks!). It looks like the PSC part 31289 that I asked about is a good fit for the earlier one. Thanks very much, Skip, for your confirmation with the photo that shows that light on your nice engine 13. I'm going to go with that one, and probably will add the flat number board. As to stacks, I had been wondering about another PSC stack, #31449, that looked possible for the C&S "shotgun" type. I found one for sale on Ebay and the photo there shows it much better than the tiny crude diagram in the PSC catalogue. It looks good so I'm getting it- hope it's right!

John Greenly

Lansing, NY |

|

John, I think the hinges are simply a convenient device to align the plow to quickly install (and uninstall) it. Chain it to a support above, slide it over the drawbar extension, line up the hinges and start hammering the pins in! Finis!

Keith Hayes

Leadville in Sn3 |

|

This post was updated on .

Or, a hold-over from the days of the Butterfly plow which was raised by block and tackle, rendered inoperable by the installation of automatic front couplers.

John, see: http://coloradosouthern.blogspot.co.nz/2014/01/additional-wreck-photograph.html EDIT: Additional Pictures: http://c-sng-discussion-forum.41377.n7.nabble.com/Butterfly-Snow-Plow-Plans-tp8302p8305.html

UpSideDownC

in New Zealand |

|

In reply to this post by Keith Hayes

I would agree with Keith...not hinges but a convenient way for the alignment and attachment of the plow. In use the plow would be supported by the engine frame and end beam...and perhaps by the drawbar but that might not support it either. I see no reason why or how the plow would need to or want to be able to hinge upward. These attachment "hinges" and pins could be easily banged out by a blacksmith too... Best, Todd Ferguson Sent from my iPad

|

|

In reply to this post by Keith Hayes

Yup, makes perfect sense to me, thanks all for your replies!

John

John Greenly

Lansing, NY |

|

In reply to this post by Todd A Ferguson

Todd, the C&S railroaders have been described (in print) as "the snow bucking-est fools" with the use of their Butterfly plows that(before the introduction of Knuckle couplers), a technique that involved hitting the drifts as hard as possible, raising the Plow and reversing the loco out. I'll see if I can find the reference tonight.

UpSideDownC

in New Zealand |

|

In reply to this post by John Greenly

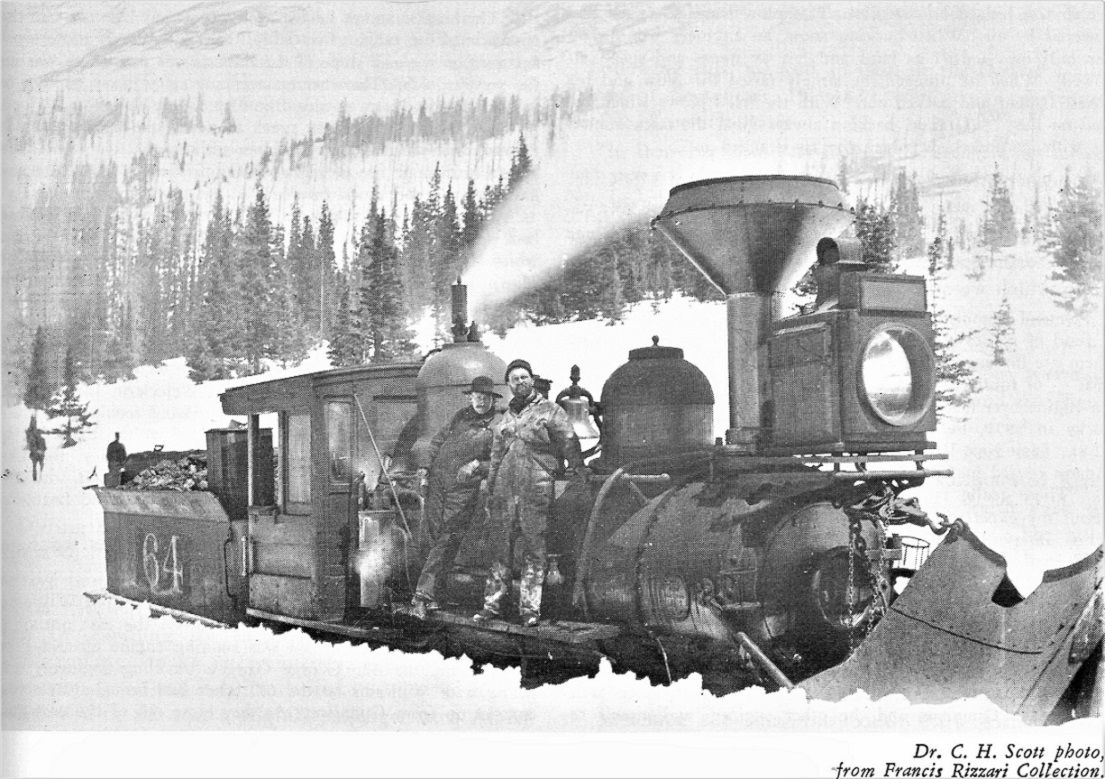

What about the photo of C&S 64 on p317 of DSP&P Memorial with the plow in raised position -caption indicates it was for backing out of snowdrifts.

|

|

Thanks for reminding us of this one, Robert.

Dr Scott could always take a great photo!

Jim Courtney

Poulsbo, WA |

Some more pics of the plow on C&S 60 |

|

This post was updated on .

In reply to this post by Jim Courtney

Yes, thanks Robert, and Jim,

I thought I'd seen a picture like that somewhere too. Very neat to see the chain hoist used to lift the plow. So Chris is right, this is a construction that lost its function when that long drawbar for automatic couplers was installed. But now I'm wondering about the chronology. Is Dr. Scott's photo still in link-and-pin days? We see the cutout in the plow for the coupling. There's a photo of C&S 49 (caption says ca. 1905) on p.103 of the NG Pictorial Vol.VI that shows a long link sticking out through the cutout, and no holes in the plow for the pilot beam, so certainly then the plow was raise-able. Jim has told me that wooden pilot beams weren't replaced with steel until 1910 or so, so the long drawbar, or something like it to mount the knuckle coupler, would already have been used earlier with the wood pilot beam. But then there would have been no reason to continue to use hinges to mount the plow on the new steel pilot beam, the drawbar would already long since have prevented lifting. Unless everybody is right- the hinges were already on the plow, so it was simplest just to keep using them on the steel pilot beam, as Keith said, as a simple attachment method. Maybe everybody is right? Cheers, John and, TonyK, many thanks for posting the additional photos- a great help!

John Greenly

Lansing, NY |

|

...and there is the matter of the air line. So much stuff in the way when bucking snow.

Keith Hayes

Leadville in Sn3 |

|

Yes, that air line would have taken a beating if they left it on there while plowing. Dr. Scott's photo shows no sign of an air line, or a hole for one. What's going on there?

John

John Greenly

Lansing, NY |

|

This post was updated on .

The detail photos of the plow on number 60 seem to show that the airline at the pilot beam and the connection to the angle cock at the inside of the plow was connected by a flexible hose (this part of the air line only seems solid on brass locomotive models!). This air hose is disconnected in the photo, rotted away at the pilot beam end, dangling down inside the plow.

A flexible coupling of the train line between pilot beam and plow makes sense, as the train line would have to be disconnected when the plow was removed, come summertime. And plowing into drifts might cause the train line to break from the jolt, had it been solid pipe fittings. The brass plow castings on my Overland Sn3 plows are such that the long, cast coupler pocket appears to be bolted to the back framing of the plow, forward of the hinges. I had always assumed that the long coupler pocket would swing up with the plow and frame if raised, like in the old days. Both the 1933 Nixon view of number 8 and the color detail shots make it clear that the coupler pocket was firmly bolted to the pilot beam, making this impossible. The photo of C&S 64 with raised plow is dated in the book to 1900. It is quite possible that the locomotive mounted with a plow at the TOTC didn't have an air connection forward of the pilot beam, as they would always be the lead engine in snow bucking trains.

Jim Courtney

Poulsbo, WA |

|

Administrator

|

Just a couple of comments, interesting thread.

The original plow design did allow for hinges to be able to raise the plow, surely for the sole purpose of reversing if snowbound. With the advent of working couplers, the extended coupler pocket prevented lifting the plow in the field. The comment that the hinges were likely used to align for easier installation to the pilot beam is probably correct. I'd never considered that before. The chains in the plow were heavy, and used for the purpose of holding the plow steady while bucking snow. There probably had been instances when the plows could sag, so the original chains had a double purpose, to prevent sag, and to raise if necessary. The chain was connected to a hook, which may have been bolted, or in the case of #74, welded behind the headlight. It was, as stated above, looped through holes in the extended pocket. The turnbuckles would be kept tight on the line, but they were also used on every run to disconnect the chain to allow the smokebox door to be opened to bore the flues. This operation was required at Dickey on every locomotive in each direction. Lastly, as stated in another thread on the plows, there were two different sizes of these plows. #60 is the only plow of this size (42" height) used on a 2-8-0. The 42" plows were built for the B-3-C rebuilt moguls The typical plows for the 2-8-0's, including the B-4-F's, was 36", to allow the smokebox doors to open. When #60 was reworked in about 1935, it was provided with this plow for winter use, as it was almost certainly often assigned at Como as the emergency passenger engine. Because some of the Moguls had already been retired or scrapped, they probably had one or two available at the Denver Shops. As #60's smokebox door is so small, clearance was not a problem. I don't think any of these comments are in conflict with anything stated above, but may offer some clarity in how these were used. "The Buckingest Bunch" is right. Next time you visit #74 at the CRRM, check out the main frame on the right side above the pilot wheel. There is a perfect, huge weld there, where the frame broke bucking snow above Leadville. The engine could not be moved, so they left in out on the line, and backed the train back to Leadville. Mickey Hansen, who later in life was the Road Foreman of Engines in the last days of steam in the late 50's and even into the 60's, came up from Denver. They loaded welding gear, timbers and a pair of jacks and set out to repair the stranded #74. They carried all that material through heavy snow, where they jacked the plow into place and blocked it. Then Hansen welded the frame, in sub zero temperatures. When he was finished, it was exactly as it appears to this day. He thought he would have to do it again when they could get it to more friendly conditions, but to his surprise, it held up just fine. Just another testament to the skill and determination of the tough men who worked up there. |

|

I don't think it was the arrival of automatic couplers by 1903 that made the hinged plows no longer "lift-able", rather the ICC prescribed steel pilot beams that show up about 1911:

Pitkin, c.1907. Courtney collection. Prior to the new steel pilot and cast coupler pocket, there were no cutouts to accommodate (and limit plow movement by) the steel pilot beams. A long, heavy "link" was used to connect the coupler pocket on the locomotive to the slotted knuckle of the coupler of the car or locomotive ahead. Number 49 by now has an airline penetrating the plow. The small metal loop at the top "point" of the plow is still in place, to allow the plow to be lifted if necessary.

Jim Courtney

Poulsbo, WA |

|

Administrator

|

Hi Jim, interesting, and a good point. I'd agree that the steel pilot beams didn't allow the plows to be lifted, but the extended pocket also did, and was universal on the C&S.

#537 always had a wood pilot beam, and many D&RGW locomotives had them too. Even some of the large K series engines. If you find a photo of #537 with a plow, you will find no cutouts. The shops angled the wood beam so it would fit. I actually don't know about an ICC rule. If there was one there were certainly many exceptions, if not on the C&S. By the way, this raises another issue in mounting the plows. They would have had to remove the pilot cage (which they did) to fit the beam through one side, and then slide it over the other end, and then back to center. Too bad we haven't found any photos of that process. And this reminds me that the lower braces were intended to hold the plow in place from the bottom to prevent lifting. So they were secured from both top and bottom. |

«

Return to C&Sng Discussion Forum

|

1 view|%1 views

| Free forum by Nabble | Edit this page |