The Helix

123456

123456

|

Chris,

that's beautiful. I'm curious- how do you bend the rail so nicely? John

John Greenly

Lansing, NY |

|

FastTrack makes a rail bender that can also straighten bent rail. Most smaller rail can be bent or curved fairly well between you thumb and index finger by pulling it through them. Code 100 and larger gets a little tougher to hand bend.

Sent from my iPad

|

|

In reply to this post by John Greenly

Thanks, although I wouldn't quite use that term in describing any of my trackage, it does have a pleasing symmetry to it.

I bend the rail in my homemade benderframe with a bottlejack, even the Rail you see in the turnout and mainline is homemade, a ripped I-beam with flat bar welded on: the rail on the branch in the rear is actual 12Lb. I had to resort to doing that as I couldn't locate any more rails at the time. Curved switches aren't really hard to do, I think they are more daunting at first glance. I cut my teeth on the rebuilding of 2 at the local park railway that were derailing their trains all the time, the builder had no idea on how to construct a Frog, nor any clearance standards by the looks.  under reconstruction, sleepers shown were seconds in temporary use while the management argued over purchasing new of proper length. A longer length Check-rail on the diverging side was found to be necessary for the 3 axle Trucks in use.

UpSideDownC

in New Zealand |

|

Better, Chris?

I was almost out of Pliobond. After your post, I thought, heck, I need to build two more turnouts anyways, so let's be more intentional. I didn't mean to finish this one yesterday, but it took less than two hours I think. When I went to glue the rails in place, I used the radius jigs to better align the rails with the curving conditions.

Keith Hayes

Leadville in Sn3 |

|

The crossover is in! Now to wire bits up.

Don Gustafson, I didn't custom build the turnout exactly but did use my sweeps to curve the rails just past the frog. Here is the other pair of switches.  The far right route is the path into the loop; the far left is the long 30" radius siding. The near left is the main and the near right is the shorter 34" radius siding.

Keith Hayes

Leadville in Sn3 |

|

Looking better Keith.

I've never been one to like the curvature to be compromised with the inclusion of a tangent through the Frog but it does have its prototype usage, the Europeans liked them on their Feldbahns. At the local Park railway, someone of lesser standards grafted a right-hand switch into a curve instead of building a more correct Y-switch. It irked me considerably so I rebuilt it, first moving the Frog location to a better position, It was intended to rework the diverging line curve to the right to avoid that tangential exit but the Park people wouldn't allow the incursion. So it was what it is.    The tangent in foreground was realigned after this was taken, improving the "flow" into the Blades. Flow is important

UpSideDownC

in New Zealand |

Re: The Helix-Switch Symmetry.

|

I see that Keith. Looks great. Kind of fun to do.

|

|

In reply to this post by Keith Hayes

Slow but steady progress. One small length of track; one siding completed.

Chris, that team switch is all wrong. Seems like they needed a left diverging track and only had parts for a right (or vise versa). I bet the train does a funny wiggle when traveling through this stretch of track.

Keith Hayes

Leadville in Sn3 |

|

Keith, what do you mean by "that team switch is all wrong"?

When I was a young Locomotive Assistant, aka Diesel Fireman, I got a primer on building real switches as the track gang received track components and a stack of Sleepers out of which they prefabricated all new switches for the yard right outside our Loco Depot. Very interesting and served me well in a few years time making my own, first in Hon3 then 0n3, and on upwards to fullsize. Keep in mind only the Frog and frog placement is the only custom feature, the rest built from stock Rail.

UpSideDownC

in New Zealand |

|

Fat fingers: I meant tram switch.

Keith Hayes

Leadville in Sn3 |

|

The inner loop is completed.

On to switch machines and wiring. Just in time for Christmas.

Keith Hayes

Leadville in Sn3 |

|

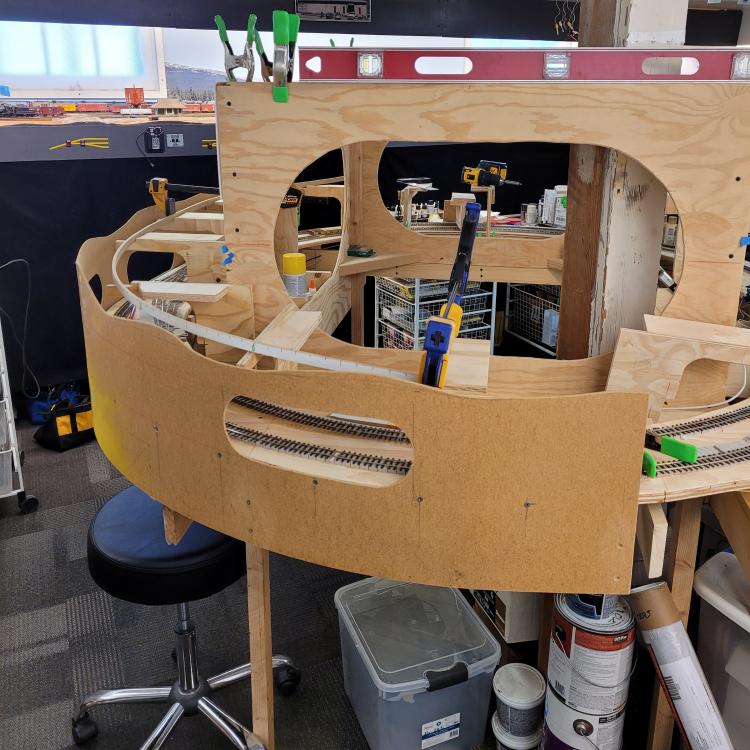

Today I laid out and cut the fascia. The large oval holes allow visual confirmation of the trains in staging and a check on the point alignment.

The track comprises the east end staging: points beyond Breckenridge. There are two lapped sidings, one of which creates a loop to test equipment on. The helix will be above this with the lowest level being exposed-- the track just west (south) of Solitude where the track starts the climb up Fremont. Painting and turnout controls await, followed by more testing.

Keith Hayes

Leadville in Sn3 |

|

This post was updated on .

Brackets for the first circuit of track up Fremont Pass are complete!

And one in position.

And one in position.

The first circuit will be open to the outside.

The first circuit will be open to the outside.

Keith Hayes

Leadville in Sn3 |

|

Here we go!

The super cold weather out discourages any kind of outdoor activity once the snow shoveling is finished. Saturday I made some track adjustments and spent a couple hours running trains around the loop and siding, watching for derailment and checking clearances. A K-37 made a visit with a train of passenger coaches as a final check.  I showed previously the plywood brackets I made to cantilever the lowest circuit of track over the outer staging loop. Today I started placing the brackets to get a consistent 2% grade. It is a bit steeper than I would like and I may have a spare 1/8" of clearance so I hope to ease off the grade on the concealed circuits. I used a piece of spline to mark off inches in order to accurately calculate the grade. I also realized I could glue a piece of plywood to greater a base for all-thread to terminate as it supports the track above. This seems the most flexible and adjustable means to support the concealed track.  Years ago, I visited Lee Kleindon to pick up my radius forms and observed his helix was reinforced by a maze of wire. You see, a helix is a spring and in some circumstances it will want to rotate helically. My hope is the internal structure I created will better resist the torsion and keep everything in place. The large openings will provide access to the concealed track from the inside.  The brackets went in easily enough. I was hoping that one of the concealed loops could be herniated to both see the train and create a water stop. Now that the helix is laid out I realize there will only be two concealed circuits. It takes a train just over a minute to traverse the loop, which seems tolerable in my experience.  I realized that I have room to extend the lowest loop to the south and this is where Kokomo will be located. It is closer to Solitude than I would like, but at least the structures won't go to waste. Also, it affords the opportunity to have the train dive into a snow shed as it moves into the concealed part of the helix! I am thinking of installing an operating train order board on the depot. This could be a good way to control traffic.  Anyhow the first bit of spline is in place. Onward!

Keith Hayes

Leadville in Sn3 |

The spline is mostly in creating about 3/4 of the first circuit. Eons ago, Darrell advised me to use 1/4" x 1" Homabed as roadbed. Ties overhang the roadbed just a bit and the ballast falls away realistically. As the layout has progressed, have evolved my technique and it continues here. The spline been planed to make it level and I am installing the foam landscape base. The idea is to contour the foam to get the track above a bit.  Once the foam is in, the Homabed will go down and everything gets a coat of latex paint and sand for color and texture. The north approach to Fremont Pass is a gentle affair with the track heading up a steady grade along the creek and skimming through the toe of slopes, alternating between small cuts and fills.

Keith Hayes

Leadville in Sn3 |

|

Higher and higher, Keith!

What are the splines made of? Jim

Jim Courtney

Poulsbo, WA |

|

Very nice work Keith!!!

Sent from my iPhone On Feb 28, 2021, at 7:51 PM, Jim Courtney [via C&Sng Discussion Forum] <[hidden email]> wrote:

|

|

In reply to this post by Jim Courtney

1/4" hardboard ripped into 3/4" strips. The stuff I got has a melamine face. Not my favorite, but it has an advantage.

Keith Hayes

Leadville in Sn3 |

|

In reply to this post by Chris Walker

And even 136 lb rail is like spaghetti...

Sent from my iPhone On Dec 14, 2019, at 4:06 PM, Chris Walker [via C&Sng Discussion Forum] <[hidden email]> wrote:

|

|

I used 1/8” hardboard because 1/4” is hard to find in Ireland.

After ripping 4 sheets of it, though, I wish I had tried harder to find 1/4”. It’s a little on the mind-numbing side of things. I’m using 1” strips, but these do require you to use thicker piano wire on your Tortoise switch machines. Not sure if that would be required with 3/4” strips or not. Cheers, Jeff. |

«

Return to C&Sng Discussion Forum

|

1 view|%1 views

| Free forum by Nabble | Edit this page |