What's on your workbench, April 2020?

What's on your workbench, April 2020?

|

Is it April? I have lost track. The office has been busy, so I have not had much modeling time. I have not been terribly inspired, either. I realized I have a bunch of unfinished projects and I had best finish them before the loose parts start to disappear. Some already have.

I got the Birdseye tank pretty much wrapped up, and the Kokomo tank too. I have the Leadville roundhouse painted, but need another coat that is a bit more brown than red.  I started an 800-series drop-bottom gon and have that pretty far along. Years ago I started a Triangle/Weisman P3 coal. The kit was missing the stakes and I set it aside. I finally thought to have Keith send me the stakes and now I can finally finish that kit. Speaking of coals, I have one last P1 to build. Mike McKenzie graciously sent me some etched brass corner irons and I set aside a set of tapered stakes to create an as-built version. I got some as-built decals, too to make a nicely weathered lettering job. That project should be next on the list. But...needing a break from the DB gon project (the chain rolls are a buggar!), I got out one of Ol' Bill's '34 Ford kits. This is a dump truck and I am modeling it with the hood and door open.

Keith Hayes

Leadville in Sn3 |

Re: What's on your workbench, April 2020?

|

Hi guys,

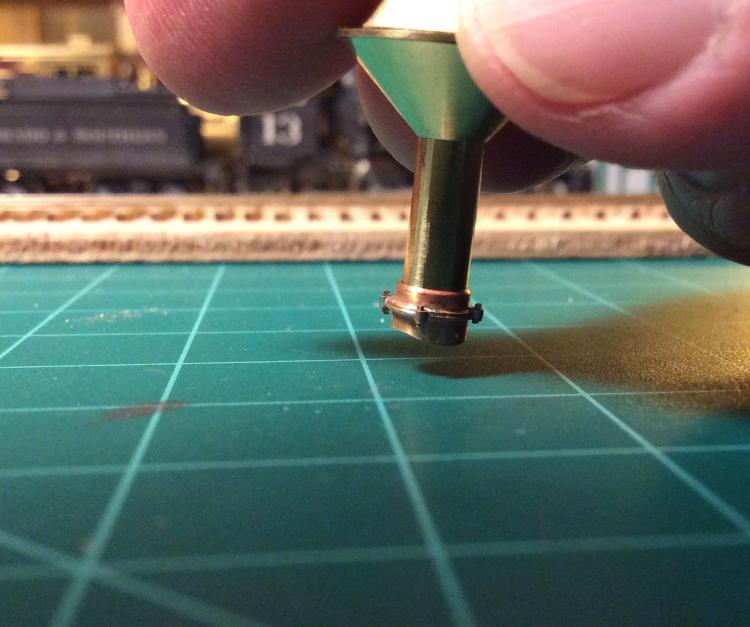

I have an exciting new arrival on my workbench!  I've been thinking of getting a small lathe for many years, but since I have access to excellent professional machines in my lab shop I didn't really need to have one at home. Also I was never very attracted to the Sherline lathe. Though it certainly can do excellent work I never would get over having only the painfully slow leadscrew to move the carriage, I know I would get frustrated with that immediately. And also they are quite expensive. But then just recently I found out about the Taig lathe, and here I am stuck at home, and... well, here it is! It arrived two weeks ago, and I love it. It's a surprisingly capable machine, especially at such a modest price. All US made, and very cleverly at that. It operates like a proper lathe, not a toy. It has nice fast z-axis travel, with the crank mounted on the carriage where it belongs, coupled to a really excellent power feed, simple but delicately contollable. I got the version with a headstock that uses the excellent industry standard ER collets. This photo was during the first day as I was tuning it up, measuring things like bed flatness and stiffness-- very impressive. Spindle and collet runout measured out at the end of that drill chuck arbor in the photo is no more than two tenths of a thousandth. The bed damps vibrations very well for such a light little thing, and you get silky surface finishes with the power feed. I'm using a nice variable speed DC motor that Igot cheap on Ebay. This is a real pleasure!!! So, I've started to make some parts. I'd been thinking more and more that I'd really like to backdate one of my engines to McConnell stack and Columbine lettering days. Last week I finally decided to take the plunge, using my little old PFM mogul that I had lettered No. 13:  I'm just starting, but this is already turning out to be an interesting project, to say the least. When I went to shorten the smokebox I dscovered that the boiler from cab to the back of the smokebox was 6" too short, and thus the smokebox was 6" too long behind the centerline of the cylinders where the stack must sit. This made it impossible to just shorten the front of the smokebox to the right length. So I unsoldered the boiler from the cab and moved it forward 6", thus allowing the correct smokebox position and length, but thereby putting the threaded mounting hole in the bottom of the smokebox in the wrong place. That's fixed now. The next photo shows the present state of affairs. The cab and boiler are not attached to each other, but I will make up the boiler length and hide the join under a jacket band that belongs right in front of the cab anyway; the bands were missing on the model.  Of course, practically everything else is wrong too. Need to make whole new wood pilot assembly, new mount for the air tank getting rid of the generator, make new more correct domes (fun on the lathe!!), replace the air pump with a correct smaller one, etc., etc.... Anyway, the whole project is basically an excuse to make a McConnell stack. As far as I know they aren't available in HO scale. I just finished the bottom end tonight, made on the lathe, including the flanges and bolts of the junction between the stack and base:  Those little bits weren't very easy to make. Or to solder together! This was fun for me, but it makes me think about all the effort that went into making the patterns for castings of things like stacks that we all buy for a few bucks. Or air pumps, for instance. Wow. Think of what this hobby would be like without people like Cliff Grandt, and whoever made all the thousands of patterns for PSC.... The rest of my stack is not turned, instead I made the barrel and cones of rolled-up .005" sheet. This set of parts was a test to see if I could do it, and also to see if I had the dimensions right. The flange piece between the two cones is too thick, I'll re-make that. Anyway, the idea is that by building the stack this way I can eventually emboss rivets and seams in all the parts, like the real thing. This'll keep me happily occupied! Cheers, John

John Greenly

Lansing, NY |

Re: What's on your workbench, April 2020?

|

Great work.

Bill Uffelman

|

|

In reply to this post by John Greenly

Wow John! Congratulations on your new toy!

The number 13 is one of my favorites. Mine is late in its life just before scrapping (or overhauling for a longer life in some fantasy world) And your backdated one will really add to the fleet. I love seeing your work. Like you I have access to a larger lathe, but I have been thinking about adding a small lathe to my work bench. I'll have to take a look at the Taig. Thanks a lot for your post and keep us up to date as your lovely #13 progresses. Skip Egdorf Los Alamos, New Mexico

Skip Egdorf

|

Re: What's on your workbench, April 2020?

|

Hi Skip,

thanks! If you want to look into the Taig machines (they make a very capable mill too, I foresee a CNC Taig mill in my shop someday for production runs of small parts) go to Nick Carter's website (search Nick Carter Taig). He is a Taig dealer, gives 10% off everything, but more important, his information pages are a great resource, far more and better information than Taig's own website, including many contributions from other Taig users. I bought my lathe from him and he was a great help to me, answering questions about what I should and should not get for my intended uses. I'm actually finding this lathe nicer to use for small parts than the wonderful Hardinge collet lathe we have in the shop. That's partly because it's so compact on the worktable that I can sit down comfortably and safely get right up close to small things with a magnifier headset to see them well. You need high spindle speeds for very small work diameter and this one goes up above 5000 rpm, smooth and much quieter than a bigger machine, and with the work in a collet there's nothing spinning dangerously near your face when you're working close. I'll stop here since this is far from C&S subject matter, but if you get serious about this feel free to correspond with me directly, I can give my perspective on uses. By the way, I do remember photos you posted of your #13 some time ago, it's a fine one! John

John Greenly

Lansing, NY |

Re: What's on your workbench, April 2020?

|

No, no. Us C&S folks are in to our machine tools. No need to stop.

Just to show that "great" minds think alike, I picked up a Cowells about 3 weeks ago. Pictures to follow.... |

Re: What's on your workbench, April 2020?

|

heheheheh ! My drill-mill had its own attendant.

UpSideDownC

in New Zealand |

Re: What's on your workbench, April 2020? Flanger #015 Update

|

Administrator

|

In reply to this post by Keith Hayes

Hi, it's been a while since I posted any goings on in Dickey, and since April has almost run out, and because I do have evidence of progress on my workbench, here goes.

Any C&S On3 modeler needs to be watching for a stray pair of San Juan C&S ACF Trucks, that were produced about the time Cimmaron Models ran their excellent cast resin Type 1 Coal Cars. Bob Stears assures me that they will be added to the line as time allows in the future. And he would know. You may recall my C&S #015 Flanger which I built three years ago using parts from both Wiseman's reissue of the Durango Press RGS Drag Flanger and parts from San Juan's D&RGW Flanger, with stripwood cut to length using both the C&S folio sheet found in the archives here, and a lot of study of what photos exist of the prototype. Unfortunately, one of the most prominent features of #015 are the ACF Trucks. Which I didn't have, and instead used trucks from the Wiseman kit. Recently, Bob sent me a pair of the rare as hen's teeth trucks, possibly the last spares he had, for use on the flanger and here they are. You'll never get a better view of these jewels than under a flanger. It took a little work to adjust the bolsters, as the coupler height and the 2" clearance of the blade over the railhead provided a small window of tolerance. But the flanger was built with this modification in mind, and it went easily. Also pictured is a glimpse of part of my "workbench", which passes for a workbench in the same way my "Layout" passes for a layout. Is less really more? Maybe. Maybe it is. Thanks again, Bob! Hope you are all doing well through these weeks and however long it takes.

|

Re: What's on your workbench, April 2020?

|

Administrator

|

In reply to this post by John Greenly

Beautiful work, John!

|

Re: What's on your workbench, April 2020?

|

I promised pictures of my new toy and then failed to deliver. Well, better late than never:

I've also been doing a bit of scenery between Jefferson and Kokomo:   And now something that's *actually* on my bench: an adit for an abandoned mine. The assembled box was supposed to be finished, but enough light gets in to see the back. So I'm now adding a few closely spaced but decreasing size frames to try and force some perspective at the back.  |

Re: What's on your workbench, April 2020?

|

Administrator

|

Fantastic stuff, Jeff. Your work in HOn3 is mind-boggling. You prove that less space is more. Way more.

|

Re: What's on your workbench, April 2020?

|

This post was updated on .

Mike,

that flanger is an absolute beauty-- even more than that, it embodies so much research and accurate re-creation. I have a Durango Press kit in HO sitting on the shelf, and your model will be a great resource and inspiration when I get to it someday. I envy those trucks too, since as far as I know there is no C&S ACF truck available in HOn3. Jeff, Wow, that lathe is a very serious machine. I looked it up on Cowells' website. Thread cutting, gear cutting, all sorts of excellent attachments. Congratulations on your acquisition, I look forward to hearing how you like it. That machine really strikes a chord for me, it's a symbol of the wonderful tradition of British model engineering that my great uncle Henry Greenly devoted his life to encouraging with all his books, articles, plans, his many live steam designs built by Bassett-Lowke from O scale to 15" gauge, etc. Someday... maybe I'll try to build one of his designs. This reminds me of a delightful old book (kindle version available on Amazon https://www.amazon.com/Trustee-Toolroom-Norway-Nevil-Shute-ebook/dp/B084ZDJX1W/ref=sr_1_1?crid=TDWKZUKG34GU&dchild=1&keywords=trustee+from+the+toolroom+by+nevil+shute&qid=1588202739&sprefix=trustee%2Caps%2C153&sr=8-1) that I'd like to recommend to anyone who needs an escape from present times. It's an improbable yarn about a character whose entirely unassuming life, spent mostly in his basement workshop, was devoted to designing, building and writing about engineering models. Never having been out of England, he nevertheless took on a crazy adventure to the south pacific islands, dependent on the kindness of strangers, and driven by a noble and naive sense of responsibility and good nature. "Trustee from the Toolroom" by Nevil Shute. And Jeff, that scenery... I am speechless with admiration. Someday I have to get over there and see it in person. John

John Greenly

Lansing, NY |

Re: What's on your workbench, April 2020?

|

John,

Your mention of the book by Henry Greenly made stop and go on a search in my library. I have a reprint copy of his book " Model Engineering , A Guide to Model Workshop Practice " . My reprint is by Lindsay Publications and is a great read . I also can recommend the book " Trustee from the Toolroom " by Nevil Shute . A really good read. Thanks for sharing this information. Charles M |

«

Return to C&Sng Discussion Forum

|

1 view|%1 views

| Free forum by Nabble | Edit this page |