John,

I have used a standard soldering iron for over 60 years. I have built brass models using an iron and a jeweler's torch for most of that time.

I think you will find that a variable heat soldering iron will be just fine. My current iron has a maximum heat output of 45 watts. That has been fine for working in HOn3. If I need more heat than that, I use my 2-bottle jeweler's torch.

I will say that when soldering, practice and more practice. I use an automatic heat adjustment soldering in my work every day. The automatic unit is a real treat. If the unit didn't cost $500.00, I would have one for my use at home. The unit has changeable tips you can select, and they have a range of heat output depending on the size. The largest heating element is probably 100 watts, the smallest 15 watts.

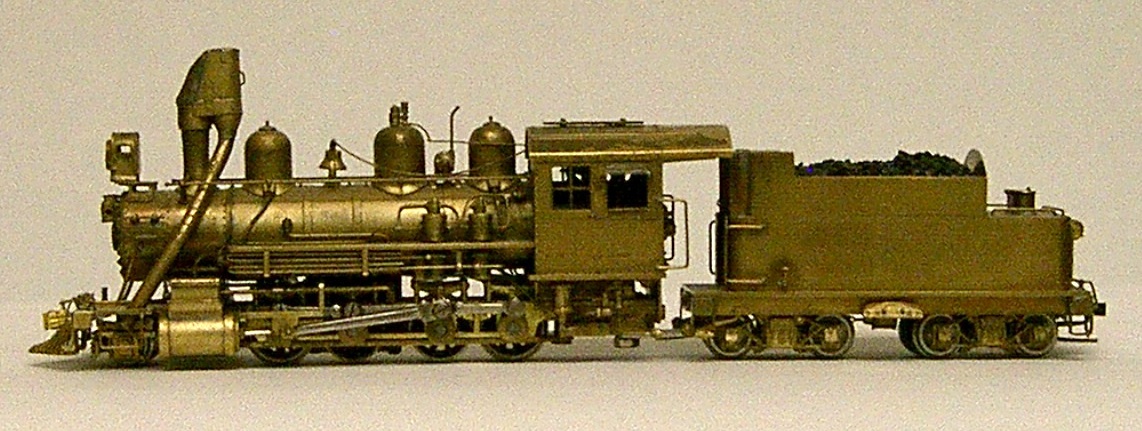

My CB&Q 537 is based on a Balboa C-21 locomotive.

Charles M.