Roof Hatches, Mill Car Loader, and Bumping Tables

Roof Hatches, Mill Car Loader, and Bumping Tables

|

Administrator

|

The following posts were moved from the Freight Car Ratio thread.

|

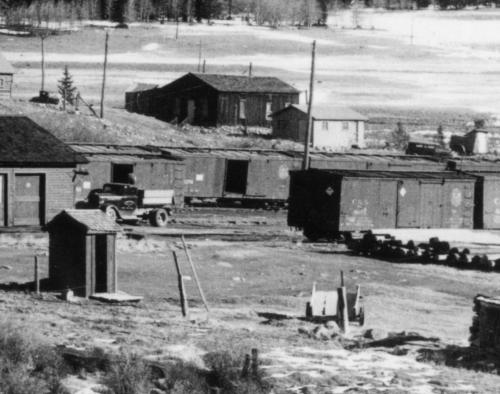

Well nine years later perhaps there might possibly be a clue as to why there were roof hatch box cars going to Black Hawk. Or at least a guess..  .. In my endless quest to model the Bobtail I was looking at a little detail I had not added that puzzled me a bit. There is a high chute that shows in many photos of the Bobtail. There is obviously not a bin above. The top above does look a bit like a conveyor head. DPL X-2052 .. In my endless quest to model the Bobtail I was looking at a little detail I had not added that puzzled me a bit. There is a high chute that shows in many photos of the Bobtail. There is obviously not a bin above. The top above does look a bit like a conveyor head. DPL X-2052

Well in a completely unrelated search I accidentally came across this photo of an unrelated mill in Idaho Springs entitled "concentrates ready for loading" Light bulb! DPL X-60603  Although this chute could be used for gons it would make sense to load concentrates into boxcars with hatches. I think on the Bobtail I will add a conveyor and chute and a small bin on the base plus bagged concentrate. There are no photos of the inside front so I am making it up as I go. I have already rearranged the concentrating tables because my mill is far shallower. The front wall also had some shortening/ rearrangement of the doors to get a usable loading dock door.  Jim

Jim Curran

|

|

Administrator

|

Wow! This is a blast from the past. Thanks for digging this back up.

As it happens, Keith drove over from Leadville to Dickey on Saturday and he had an interesting take on the number of Gons and Engines required to feed the feeding needs of the railroad's coaling facilities. I have 8 boxcars in service on my layout, and 10 Coal Gons, most of which (6-8) are in use to populate the needs of the coal dock. Given the needs for coal at all the facilities on the Mainline to Leadville, of the 15-20 cars used on the three long freights per week West of Denver, there were probably 5 loads of Coal in each train as far as Pine Grove and Como, indicating that one of the 3-4 locomotives on each train were hauling tonnage for the railroad's coal. Coal to Dickey and Leadville would have been less tonnage for coal. My Freight Roster: 10 Coal Gons (6 phase 3, 1 Phase 2, 2 Phase 1, 1 Phase 0) 8 Box (4 Phase 3, 3 Phase 2, 1 Phase 1) 2 Refrigerator (Phase 3) 3 Tank (High Dome CONX) 1 flat (Phase 3) 5 Stock (3 Phase 3, 2 Phase 2) I'll add a few more eventually, but not many. |

I certainly need to add more stock- although I have quite a few kits in my stash. I am lacking in gons mainly and in HOn3 the Micro Trains are pretty much being scalped on ebay. I think the Grandt lines are back in production? Really though I need phase one and two gons. Probably going to do some scratchbuilding on them although I do have one Labelle kit already. I do have to admire your self control Mike- not wanting to add more. Not common among us model railroaders in the collecting department. I would still like someone to explain why I have four pickle tank cars and two helium cars in my standard gauge collection and where they came from. I must have blacked out at a train show at one point.

Jim

Jim Curran

|

|

This post was updated on .

If you need more HOn3 coal cars, Bill Meredith's Co-Op offering from Leadville Designs of the 1902 coal cars (phase 1) should be available to ship by the end of the month:

https://leadvilledesigns.com/collections/ho-hon3/products/copy-of-on3-c-s-type-1-coal-car-1 The kits will have parts to do the 1898-1900 St. Charles coal cars (phase 0) as well, as the wood bodies were near identical. By the 1930's most all the St. Charles cars were gone, though. Bill also will be offering the correct ASF HOn3 trucks for the cars as well: https://leadvilledesigns.com/collections/ho-hon3/products/c-s-4-acf-trucks-complete I'm awaiting my Sn3 kits . . .

Jim Courtney

Poulsbo, WA |

I forgot he was releasing these- tempting. I was thinking scratchbuilding as I have the brake gear trucks and so much stripwood I don't think I will ever use up. Jim

Jim Curran

|

Fifty Gold Mines Mill Car Loader.

|

In reply to this post by drgwcs

Jim,

I hate to pour cold water on your discovery but on reflection of several factors I'd be rather sure it wasn't for loading the "roofhatch" Boxcars. I do realise we all strive to find validation in our model world, done it myself back in the day.

That photo DPL X-2052 is early, after construction of the last Mill on that site. Later photos of the Mill show the apperatus removed, the last use was 1935 according to The Gilpin Railroad Era by Abbott and McCoy: see pg 277. The Roofhatch car(s) were up Clear Creek (DPL OP-6260) in 1939 and(DPL OP-6282) in 1941, long after severance of a Leadville connection and the(probable) traffic use specifically for the Climax Mill expansion. Your concentrates image(DPL X-60603) is taken inside the Clear Creek Mill at Empire(Jct); I didn't at the time see the need to include it: see http://c-sng-discussion-forum.254.s1.nabble.com/Silver-Mountain-Mill-At-Empire-Station-tp18080.html I had written the DPL after the Silver Mountain Mill article to update their caption correcting the stated location of those photos taken there but they didn't action it for some reason still listing it as being at I.S. Your modelling efforts in compressing the Fifty to avoid going broke on detail castings is admired. fwiw.

UpSideDownC

in New Zealand |

|

Administrator

|

In reply to this post by drgwcs

Thanks, Jim. Rather than pure "self control", I really don't have room for more on the railroad. As it is, I usually keep 9 or 10 cars off the layout so I don't have the yard too congested. But I really do need the Coal Gons out there because of the Coal dock. I usually have three or four on the ramp, and three or four on a storage track across from the ramp. They vary in number between loads and empties so they don't look the same all the time. The other two or three cars run in the train, again varying between loads and empties. With the remaining stock I have, I can mix the consists so the trains don't always look the same. Sometimes one, two, or no reefers and tanks and a flatcar can really mix things up without having too many cars sitting around choking up the yard. So, it's just a little sleight of hand to convey the impression of a larger operation than I have room for.

|

|

This post was updated on .

In reply to this post by Chris Walker

Well you probably saved me some hassle there Cris- I was wondering how to fit that chute in. Interesting to hear it was gone later. It also does not show in a photo in the prospectus. I guess I was trying to cover my bases- as it seems like info always crops up AFTER I finish a model. Your info is always a help. The concentrate photo was just what triggered the idea. The compression of the mill was not really by choice. My Black Hawk scene is in "found space" and is a foot wide. (any wider and there would not be an aisle) Thus the mill is shallower than the prototype. That necessitated the single row of Wilfleys but it works visually as the stamps are a bit wider than the prototypes. I am actually scratchbuilding the Wilfleys as there is not really a kit that resembles the ones in the Bobtail. That has been true of all the machinery including the stamps and the feeders. I have done some goofball things in building this. I was puzzling over how to build the feeder bins for example and one morning I noticed that the disposable razor I was using had a handle shape that was close to the bins- so there are four razors in my model.  The mill is at the end of the Black Hawk peninsula and faces into the room- it will have a clear wall and the whole thing is lighted. It is certainly not an exact interior because of these things and quite frankly some things such as the arrangement of the front of the mill and top of the bins are unknown. The mill is at the end of the Black Hawk peninsula and faces into the room- it will have a clear wall and the whole thing is lighted. It is certainly not an exact interior because of these things and quite frankly some things such as the arrangement of the front of the mill and top of the bins are unknown.

Thanks Jim

Jim Curran

|

Re: Fifty Gold Mines Mill Car Loader, and Bumping Tables

|

I can relate to your angst Jim.

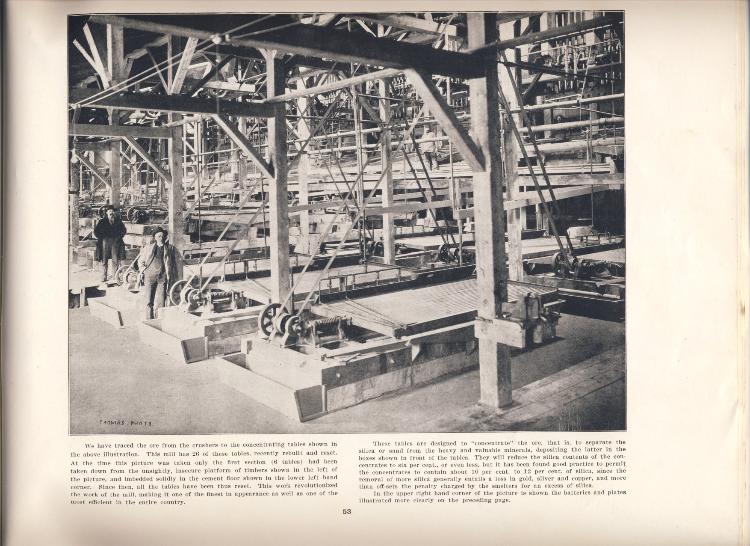

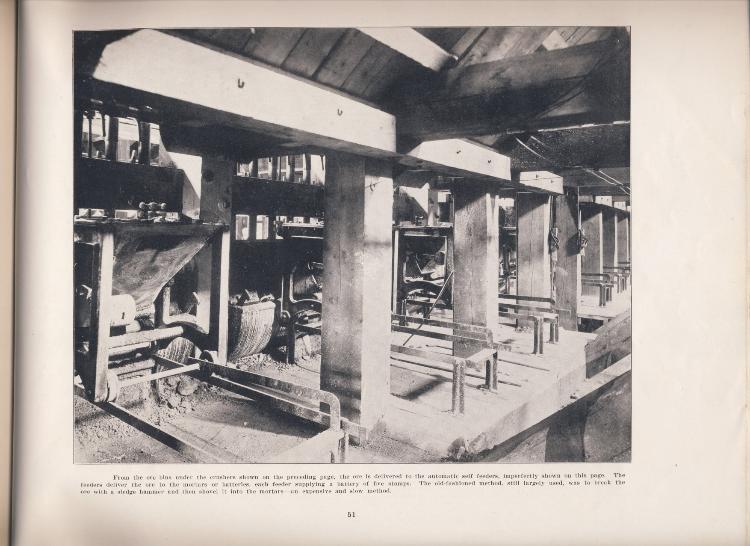

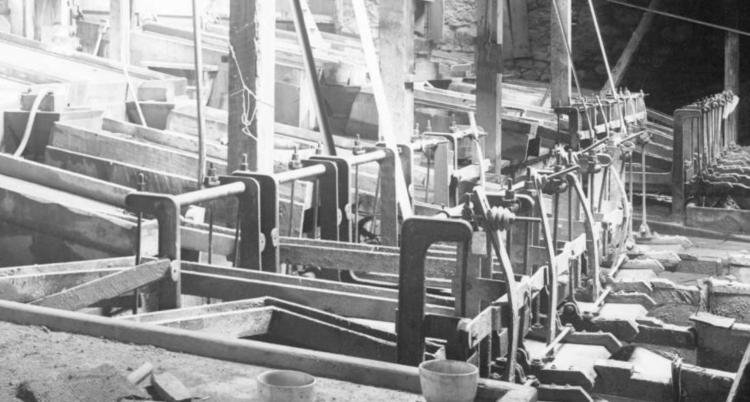

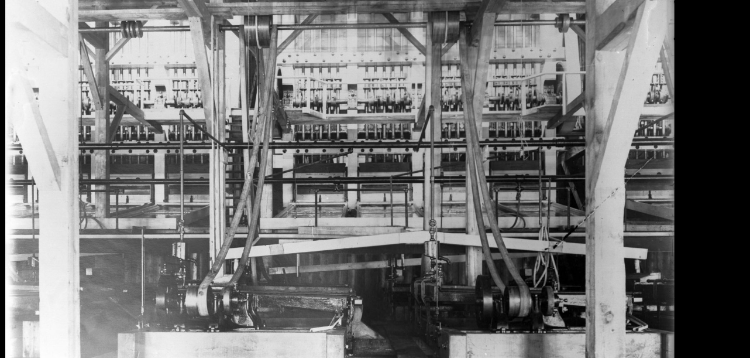

DPL L592  It appeared (to me) that the feed chute was propped up to clear when not in use. The rubber conveyor belt system was developed in the early 1890's and was quickly adopted in the iron mining industry; whether that early date was uptaken in Black Hawk I can't say. DPL X-2051  Mills varied in equipment and process's with new technologies and methods developed all the time. You mentioned the Wilfly's, there was another more common shaker table used and manufactured right there in the Central City and Black Hawk foundries of McFarland & Co.; the Gilpin Bumping Tables. Does your Prospectus call that out specifically? The USGS only listed "Concentrating Tables" in 1917 Denver Public Library images K-178, X-60606 I'm sure there are others  The 911MetalurgistBlog has numerous Mill machinery images, that may help. https://www.911metallurgist.com/blog/small-ore-feeders "Supplying the Mining World"was another book that dealt mainly with the California market. As for the top of the Orefeeders, I've seen a few variations : see DPL X-63123 for one example. Maybe Keith Pashina will see this and add something.

UpSideDownC

in New Zealand |

Re: Fifty Gold Mines Mill Car Loader, and Bumping Tables

|

Administrator

|

Joe and I are having dinner with Keith in about two hours. I will tell him to check it out when he gets back to his hotel tonight.

|

|

This post was updated on .

In reply to this post by Chris Walker

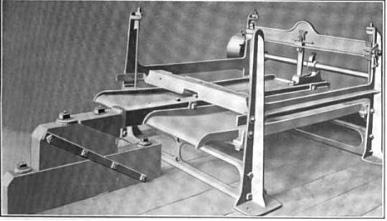

Anymore "Wilfley tables" is almost used as a generic term and I used it as such. They are listed as shaker tables or concentrator tables interchangeably on mill information. The prospectus does not mention a manufacturer for the tables or feeders. I have not really found a match to them otherwise despite looking through the 911 metallurgist, the stampmill man or a couple of catalogs on archive. That was another reason to scratchbuild. (just glad these things don't need to operate) I do have a full copy of the prospectus over on the C&S Facebook group in the album section. It was provided courtesy of Mark Greaves in the Colorado Mines and Mining group. It is entitled "Gathering Gold" and I suspect it was intended originally for investors that came in 1906. Here are the shaker tables- I am currently working on them and have the frame assembled and the table top made. Do these seem to be any sort of a match to the Gilpin Bumping Tables? I have not seen a pic of them as far as I know.  The feeders do resemble slightly a Heandy but do not match anything exactly  Mine were built using the smallest I beam I could find and are slightly more beefy. I left the bottom straight- after several inconsistent attempts to bend a curve. The rails in the bottom I found too light to duplicate exactly I had a hard time trying to make the bin with its curved spout till I came up with the disposable razors. This makes the bin somewhat thick but does not show in the completed structure.  Jim

Jim Curran

|

Re: Fifty Gold Mines Mill Car Loader, and Bumping Tables

|

Those are nice looking bumping tables, Jim. There were many types of machines that all did similar things to separate the concentrates, yet differed greatly in their details.

The Gilpin County Bumping Table was I believe invented by MacFarlane, a Central City-based machinist who went on to construct a sizable machine shop down in Black Hawk, served by a spur off of the C&S. There is a good description of it in the book, "Gilpin County Gold", which discusses MacFarlane's career, and in the book, "Drills and Mills" by Will Meyerreicks (pages 206-7). Will Meyerreicks said this about the Gilpin County Bumping Table: "The Gilpin County Concentrator... was a fine-sand concentrator using a continuous, smooth table. It was bumped about 1.5-3 inches, and from 120-180 times a minute, at the end of the table by means of a spring, cam and bumping post. The bump causes the ore to move up the slope and stratify, lighter particles moving above the more dense ones below. Water would then wash the lighter particles down slope and the heavier particles would continue up the slope. The table could treat 4-5 tons per 24 hours...Tables that used a bumping post lost favor chiefly because of the disintegrating effect of the bump on the mill building." The Gilpin County bumping table did just that, it bumped the sloped riffled table to separate heavier particles (the metals) from the rest. I am no mining engineer, but the Wilfley tables seemed to have more sophisticated motion. The local milling men seemed to all have strong opinions on what process worked best, and especially if they were custom mills, needed to modify the combination of processes used to accommodate the different ores. Here is an image of the Gilpin County Bumping table:  And here is a row of them in the Hidden Treasure Mill:  And in another mill (I do not know which one):  As an example of how mills may have used differing combinations of machines, a description of the Randolph Mill in Black Hawk (served by the C&S and Gilpin Tram), was that it had machinery that included: " 50 stamps, 10 plates, 10 bumping tables, and used water power. In 1914, the operating part of mill consisted of crusher, Challenge feeders, 10 750-pound stamps (53 drops a minute), amalgamation plates, 2 Gilpin County bumping tables, 6 Wilfey tables, and had electric power. Its capacity was 75-100 tons daily." I always find the whole milling process and equipment so fascinating.

Keith Pashina

Narrow-minded in Arizona |

Re: Fifty Gold Mines Mill Car Loader, and Bumping Tables

|

Administrator

|

Hi, all. I would like to move these last couple of posts out of the "Ratio" thread and start a new one. But I can't do it until later today. Thanks for your contributions and your patience!

Mike |

That is fantastic- I knew we were going wayyyyy off topic but hated to start a new thread and loose the posts. That's good software that allows you to do that. Wish sometimes I could do this in the Facebook group. Thanks Jim

Jim Curran

|

Re: Fifty Gold Mines Mill Car Loader, and Bumping Tables

|

When I can find my notes relating to the Renshaw Mill: I'm thinking there was a reference to the Bumping Tables being replaced with the Frue Vanners......

see JimC's postcard view post.. http://c-sng-discussion-forum.254.s1.nabble.com/Idaho-Springs-Mid-Town-Ore-Processing-Part-2-tp2167p18428.html Keith: thanks for jumping in with that info. Your "And in another mill (I do not know which one):" (DPL X-60606) is inside the Perigo Mill, the image DPL X-61771 shows the Mill exterior and was an unidentified Mill photo of this that caught my eye a few years back. Pete McFarlands story is one for books that's for sure. Thanks to JimC for the nudge, and the resurrection of the Car Ratio thread. I enjoyed a re-read and spent several minutes questioning the anomaly of my Mining tramway having 60% Timbercars and only 20% Orecars. Perhaps that is an excuse to build some more?

UpSideDownC

in New Zealand |

|

In reply to this post by Keith Pashina

I had seen that bottom photo and wondered if those might be the Gilpin model. For the equipment in the Bobtail there is no real match I have found and there is no name above the stamps (at least that you can tell from the pictures) I have seen a picture in the DPL that is supposedly the Iron City mill that may be an earlier photo of the Bobtail as the stamps look to be the same model BUT the tables are different from what I see (or at least have been heavily modified) The head mechanism appears the same but the table itself is different. I also see some differences in the walkway framing in front of the stamps. When the prospectus was printed they were in the process of moving the tables from cribbing down to the concrete floor so the fat that these are on cribbing is irreverent. What makes me suspect it is the Bobtail is that the stamps barely visible to the extreme right are further forward. This is where the tower/ central ore bin would have been. However the Iron City was also added on to. I go back and forth as to whether this is the Bobtail or not. I found it after I had already framed the back wall so my details would be incorrect. (That is OK- my stamps are a bit wide my mill is too shallow and there are several things that are not right or freelanced as there was not enough info and probably never will be)  It is at https://digital.denverlibrary.org/nodes/view/1118472?keywords=stamp+mill&type=all&highlights=WyJzdGFtcCIsIm1pbGwiXQ%3D%3D&lsk=2b61579f139a2ab1f0d4a4e2e37ad7c3 Jim

Jim Curran

|

|

By the way for anyone wanting to see the whole prospectus on the Fifty Gold Mines (Bobtail) we do have it over on the C&S Facebook group. It is a closed group but just send a request to join if you are on Facebook and I'll gladly get you added. (As a note I feel the groups compliment each other rather than compete and I and others have referred people here for info on many occasions)

Group link- go here first https://www.facebook.com/groups/ColoradoandSouthernNarrowGauge Link for the album on the Bobtail- (will come up as content not available if not a group member) https://www.facebook.com/media/set/?set=oa.2762521747303621&type=3

Jim Curran

|

Re: Fifty Gold Mines Mill Car Loader, and Bumping Tables

|

It’s a great group!!

|

«

Return to C&Sng Discussion Forum

|

1 view|%1 views

| Free forum by Nabble | Edit this page |