Modelling stub switches

123

123

|

I'm a couple of weeks away from having some splined subroadbed done, and was doing some research on hand-laid stub switches. There seems a bit less on-line than for split-point switches.

Anyway, I had some ideas for a "new" method: Basically, the idea would be to have the heel rails end on the middle of a PC-board tie, solder the track to some track joiners, and the track joiners to the tie. The track joiners would be cut/filed/dressed so that the side toward the moving rails would have their inside walls removed, leaving only the bottom and outside walls. They would therefore mimic the plates found on the prototype, and serve as limits to the travel of the throw. The throw bar would then be a solid brass rod, encased in black shrink-wrap. Short brass tubes would then be glued to the outside of the shrink wrap, and track joiners soldered to them. These would (in theory) keep the moving rails in gauge, and look much more like the prototype. Insane, or perhaps workable? Thanks, Jeff. |

|

If you are in the Denver area, and haven't been out to the Co. RR Museum, suggest you go look at

one of our Stub switches, We have a 3-way and several two way stubs. The biggest problem I see in modeling a stub, is the guage bars on the swing rails. You need at least 3. Also the heel has a stub block that the rail ends fit into. This also provides throw stops to the outside rails. Because the head block would be so small I don't know if one could file or mill the block. It would probably be made out of plastic. I'm not really picturing your idea of using rail jointers. If HOn3 may be more trouble than it's worth. Our biggest problem with the stubs, is the expansion that occurs in the heat of summer. Also we do have to check alighnment now and then. We don't use the stubs very often, so this check may happen every few years. fwiw keith |

|

In reply to this post by Jeff Young

Check out RAILWAY ENGINEERING and BK ENTERPRISES websites .They have kits for stub switches.

|

|

There are also the Fastracks jigs.

|

|

In reply to this post by Jeff Young

Jeff, Tim Warris at Fast Tracks has developed a method to use his jigs to build a reasonable stub switch. I may try this method as I move the layout down the canyon. There was a fellow on the NGDF that provided some background on the geometry of a true stub switch, which may differ some from a point switch. Anyway, Tim developed a reasonable workaround. There is probably a downloadable PDF on the website (http://www.handlaidtrack.com/v/vspfiles/documents/ug20.pdf). (Incidentally, I would not stop the rails over the PC board tie, but extend them just past: you want the moving rails to stop one tie space past so that you can have some spikes or pins in a wood tie to serve as a rail stop. Also, the last PC tie under the moving rails will want to have pins underneath to permit the tie to rotate slightly under the tie.)

A couple years ago, I made several overtures to Tim to design a jig for a symmetrical three-way switch as used on the Colorado narrow gauges. He has not taken on the project. BK and Steve Hatch both make fine three-way and standard stub switches. The trick to the three-way is automating the throw (if you choose to do so), and automating the power routing (if you choose to do so). I studied various options for turnouts years ago, and determined that buying a Fast Tracks jig was the most cost effective--I recall it started to pay for itself after the fifth or eighth turnout. I have built 12-15 now, and can build a turnout in a couple hours. It also allows for some customization. Tim has worked out the geometry very carefully, and the jig turns out beautiful track. Tim also has some superior videos on his website that explain how the rail wheel moves across the frog--fascinating stuff for a certain mind set. On the other hand, one reason I chose Leadville is that there is a diamond on the main where the D&RG Ibex Branch crosses just north of the roundhouse. I tried to build this from scratch a couple times, and could not make it work. So I turned to Steve Harris, and he built a fine piece of track that I will be installing soon.

Keith Hayes

Leadville in Sn3 |

|

Somewhere around 2003 Andrew Dodge had an article about building and wiring a 3-way stub switch in Model Railroader.

|

|

In reply to this post by Robert McFarland

Yeah, I have the FastTracks point tools. But I don’t use their full jigs because I try to avoid PC-board ties (just using them for throw-bars) and because I’ve got a lot of odd-shaped turnouts.

The other thing I don’t like about the FastTracks stub turnout method is that they use 4 track spikes as a bridle to hold the throw-bar down. This means that you can’t mount the switch machine under the track centreline because the hole would weaken the material the bridle is spiked into. So they put it outside the track and use a long tie. I played around with the idea a bit, and while it might work on On3 (or larger), it’s not really a runner on HOn3. However, I did find a thread (http://www.trainboard.com/grapevine/showthread.php?108931-stub-switches) by Wolfgang Dudler where he uses some Proto:87 frets and throw bars, which looks very interesting…. Cheers, Jeff. |

|

In reply to this post by Keith Hayes

> On the other hand, one reason I chose Leadville is that

> there is a diamond on the main where the D&RG Ibex > Branch crosses just north of the roundhouse. I tried to > build this from scratch a couple times, and could not make > it work. Out of curiosity, what turned out to be the difficult part? (I’ve got a non-factual crossing in Kokomo to build where my C&S crosses over the D&RGW line.) Jeff. |

|

In reply to this post by Jeff Young

It's been 30 years since I got out of Hon3, from what I can remember I used a narrow pcb tie with soldered in smallest size spikes for a Bridleiron and normal size spikes for the Headblock. Stops were square brass flats soldered on to the Headblock tie. A DPDT slideswitch was installed underneath the Bridleiron and a vertical 12thou spring steel wire was the throw rod linkage with an offshoot of same to the Harp casting. The DPDT switch was activated horizontally by 1/8 brazing rod to a knob on the Fasciapanel, sometimes these needed an R/C type elbow or crank inserted to line up the DPDT and Fascia.

That was for code55 and code40 rail. My mate bought all my Hon3 stuff and continued with the same tracklaying and turnout operating that I had used, he modelled Gunnison to Montrose with every prototype turnout in between and apart from some heat expansion, mainly in the Pliobond glued-down code40, he had no problems.

UpSideDownC

in New Zealand |

|

Chris,

You don’t mention anything to keep the bridle iron vertically located (to keep it and both moving rails from flexing up). I note that Wolfgang didn’t either. Maybe such a thing is not necessary? (I like the soldered-in spikes idea. That would be pretty similar to the proto:87 frets.) Thanks, Jeff.

|

|

Nope, nothing to prevent it from moving upwards, that isn't or shouldn't be an issue, just as it is not on the fullsized ones I've built for my 18" ga. tramway. So long as you sand all your ties level all the way through the turnout and your rail isn't bent or curved vertically, and the turnout throw rod doesn't put any pressure nor force to push the tiebar upward then there should be no problem.

Make a trial turnout on the work bench for practice perhaps if it bothers you.

UpSideDownC

in New Zealand |

|

In reply to this post by Jeff Young

Jeff, I just got flustered making the interior guardrails. I guess I have been sullied by the ease of the Fast Tracks jigs.

Out of curiosity, why don't you like PC board ties? I have had nothing but good luck. I don't mean to be evangelical, but if you don't like the way Tim proposes spiking the tie in place, consider using some wire to make a staple, or extend the tie on the short side wild a bit and hold the tie down on the outside of the rails. There are lots of ways to skin that cat. I just like the reliability of the product from the doggone jigs. And they make a somewhat tedious activity more fun for me.

Keith Hayes

Leadville in Sn3 |

|

This post was updated on .

In reply to this post by Jeff Young

Wolfgang is the guy. Thanks to him for taking some photos and documenting what most of us would otherwise walk by.

Another detail I have added to my turnouts is fish plates on the side of the rail facing the viewer. I place these on the two point rails where they join the frog, and past the frog, where that would join the rail. My fish plates are from Detail Associates. These are the 6-bolt variety, and I sometimes cut these down to 4-bolt plates. Proto-87 also makes some. It is a really small detail, but I think it does jump out when you see it.

Keith Hayes

Leadville in Sn3 |

|

In reply to this post by Keith Hayes

It’s entirely a conceptual thing. Where feasible I like to stick to the prototype in method, as well as in appearance. A lot of times it’s not feasible. For instance, I find wood rolling stock is too hard to get a scale finish on, so I often prefer styrene. But if I can spike metal rail into wood ties, I’d rather. Cheers, Jeff.

|

|

Thanks everyone for the input.

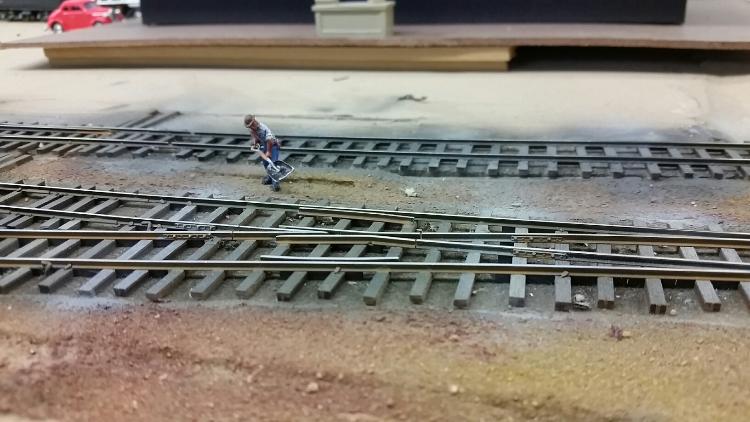

Here's the current plan: Point-of-switch centered over wide PC-board headblock, with stops soldered outside the rails (a la Wolfgang Dudley). Narrow (and thin) PC-board gauging ties 1 and 3 tie-gaps back with soldered rail joiners. Plastic faux gauge rods glued between each pair of rail joiners; joiners and rods painted black. Rest of the gauge ties hidden by covering with thin layer of dirt (their tops are the thickness of a rail joiner below the adjacent tie tops). No vertical location. Still a couple of weeks away, but I'll let you know how I get on when the time comes.... Cheers, Jeff. |

|

This post was updated on .

The head rod obviously goes in the first tie-gap back from the headblock. The bridle rods on the prototype then appear to be at gaps 3, 5, and 7, with spiking commencing on the 10th tie back.

I had only planned on a single bridle rod 3 gaps back, but if I'm going to do it at all, it would be cool to try and match the prototype. Does that seems reasonable in HOn3 with code 55 rail? Or do I need to use fewer bridle rods to limit friction at the bridle points? And does 10 ties back seem reasonable for the flex distance, or do I need shorter or longer for code 55 rail? Thanks, Jeff. Edited to use C&S terminology. |

|

|

Bill, the gauge rod bridles are shortened rail joiners soldered to a PC-board tie. The PC-board tie is then hidden by covering with dirt, while a visible faux plastic gauge rod is glued above it between the bridle joiners.

Or that’s the plan, anyway. Frogs are #6’s and #8’s. 10 ties back would be about 17’, so perhaps I want to go a bit shorter. I could keep 3 gauge rods and start spiking at the 9th tie, or drop down to 2 gauge rods (3rd and 5th gaps), and start spiking at the 7th or 8th tie. |

|

In reply to this post by Jeff Young

|

|

In reply to this post by Jeff Young

|

«

Return to C&Sng Discussion Forum

|

1 view|%1 views

| Free forum by Nabble | Edit this page |