early COLX tank cars

12

12

|

This is my first post here and I'd like to start by saying that, having stumbled upon your discussion forum, I have been absolutely fascinated by the things I've read here. The C&S seems to be a very richly complicated object of study. I greatly enjoy poring over the many wonderful historical photos you all have unearthed, and reading the tremendous accumulated knowledge to be found here.

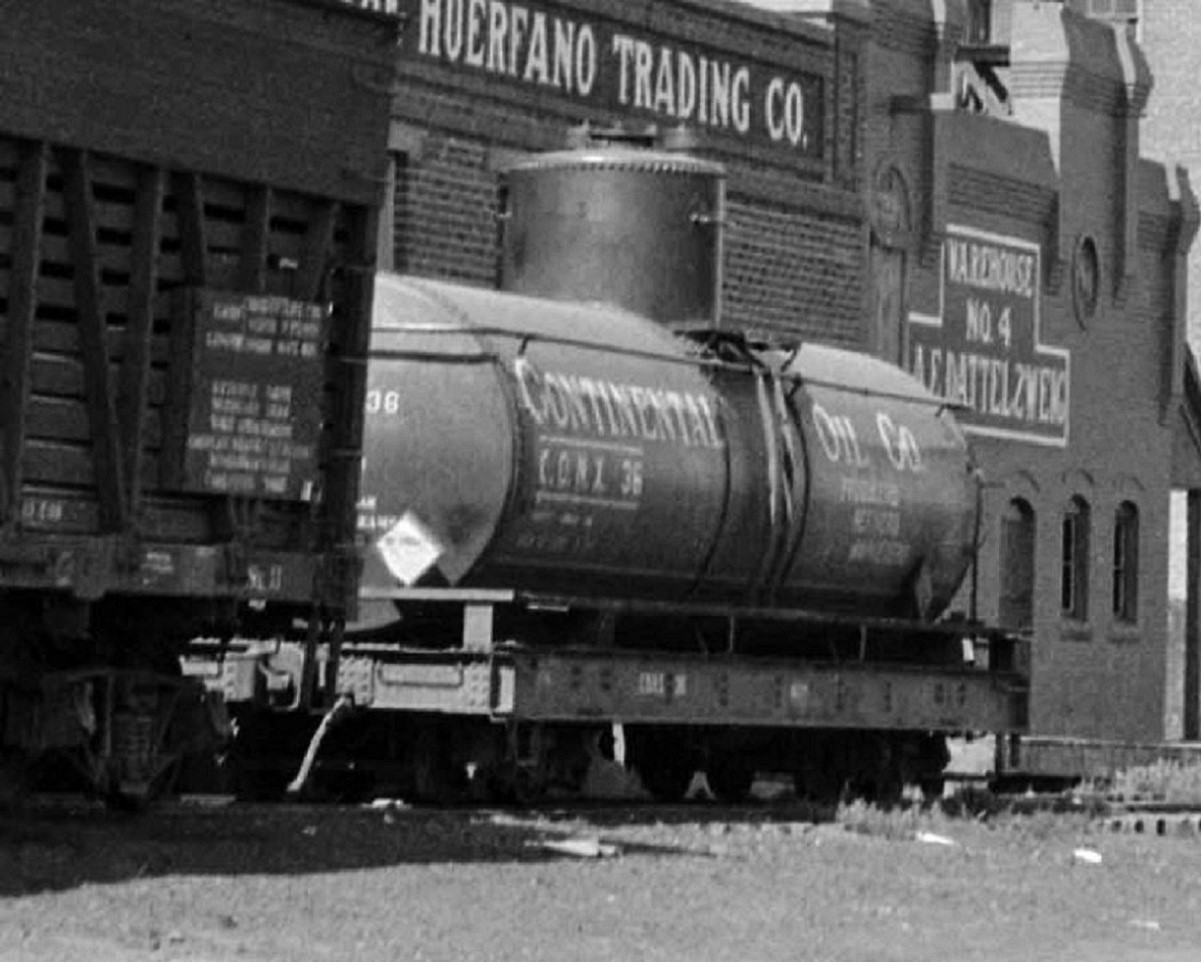

I've just begun building some HOn3 models after about 40 years away from trains. This started when I noticed on Ebay a nice little old PFM-United C&S Mogul for sale. I instantly remembered the ad on the back page of Model Railroader sometime in the Sixties that showed that engine-- how great it looked, and how much I wished I could afford the (I think) $39 price, which was out of reach for a teenager who got 35 cents for mowing the neighbor's lawn! Anyway, it turned out that I was the only bidder, so the loco is now mine. It has a very nice paint job but had the number 58 stuck on it. After a first foray into your information here I have rashly renumbered it No. 13, undoubtedly opening myself up to all sorts of wonderful puzzles as to the correctness of many details, but at least now it has the right number of wheels. And, from photos in Colo. Rail Annual no.10 I see that it survived at least two near-catastrophic derailments, once ending up with pilot wheels dangling over Clear Creek, and another almost rolling over at the very edge of a cliff, so it must be a lucky number! My second project was another Ebay item, a Grandt kit for caboose 1005, and thereby hangs a twisted, and as yet unfinished, tale that I will defer to another time, because today I have a different question. I bought a kit for CONX 5 but decided to build a different flatcar for it based on photos here of CONX 6 showing its floorless frame that may have been the original, if I understand correctly. I liked the looks of that, so I've built that car and am now ready to letter it. I'd like to put it back in the pre-CONX era, maybe around 1910 or so. Here's where I need help. So far I've not found any photo of a wood-framed car with earlier than CONOCO lettering. I have seen the one posted in another thread here of the steel-framed CONX 36 in 1925 with "Continental Oil Co." lettering. I really like the looks of that, but that was still after the change to CONX. Can someone help with how the wood-framed cars were lettered in their early, COLX days? many thanks, John Greenly

John Greenly

Lansing, NY |

|

John, I know of only two side-view photos of tank cars in Colorado, prior to 1920, both on the RGS:

In Grandt's Narrow Gauge Pictorial, Volume IV, page 127. This photo is dated c1913, the location being Telluride on the RGS. Also note the red D&RG reefer. End wreck views of COLX 8 and COLX 11 are on the following pages c1915-1919, showing the end reporting marks. Then there are the radioactive chemical cars of The Standard Chemical Co:  From Dorman's The Rio Grande Southern--An Ultimate Pictorial Study, page 55. The two cars, SCCO 7 and SCCO 6, are spotted on the Placerville house track, behind the depot. The photo is likely in the late 'teens, after US Safety Appliance hardware was applied to the D&RG drop bottom gon. Per caption, the Standard Chemical Co. was involved in exploration of uranium, radium, etc. in the Paradox Valley to the west. The company went out of business in 1922, giving an end date for the photo.

Jim Courtney

Poulsbo, WA |

|

Jim, thanks so much, this is great! In the first photo the frame does look very much like that of CONX 6 in later photos. You can see the shadows on the side sills cast by the ends of the transverse supports for the walkway along the side of the car, and there are 10 or 11 of them, similar to #6. That further reinforces my thought that the frame of #6 in the later photos is probably the original. This tank is quite different though, having a much taller dome, and the handrail is up high on the car, so it's certainly not #6. Is that possibly a number 7 showing brightly on the right part of the tank side? I'm guessing that the lettering says "Continental" on the left half and "Oil Co." on the right half of the side. The height of the letters is consistent with that lettering on the later photo of CONX 36. I don't have the RGS book to look at, but I'm guessing that the reporting mark on the end just says COLX ##? So, this is good enough for me, I know how I'll letter my COLX 6 model.

These Standard Chemical cars are really wonderful. They look to be mounted on standard decked flatcars, like the later re-mounted CONX 5 that all the kits are of, except that these have 6 equally spaced saddle supports under the tank rather than the four, positioned above the bolsters and the needle beams on the CONX cars. The tank domes look quite similar to CONX 5, though the tank may be longer, since the cars are 29' 6" long and the tank end mounts appear to be right up against the ends. Tolerating that slight inaccuracy, though, it wouldn't be hard to make up a model using the available CONX 5 tank. I might have to make a model of one of these. As a physicist, I am very cognizant of the history of radioactive elements. This photo was taken just during the time that very active experimentation was going on with radioactivity. Many people, like Marie Curie, later died from the effects of unprotected exposure to radium. I shudder to think of what was in those tank cars, and how they were handled. I'll see if I can find out something more about them. Jim, very many thanks for taking the time to dig out these photos! John Greenly Ithaca, NY

John Greenly

Lansing, NY |

|

This post was updated on .

Hey John,

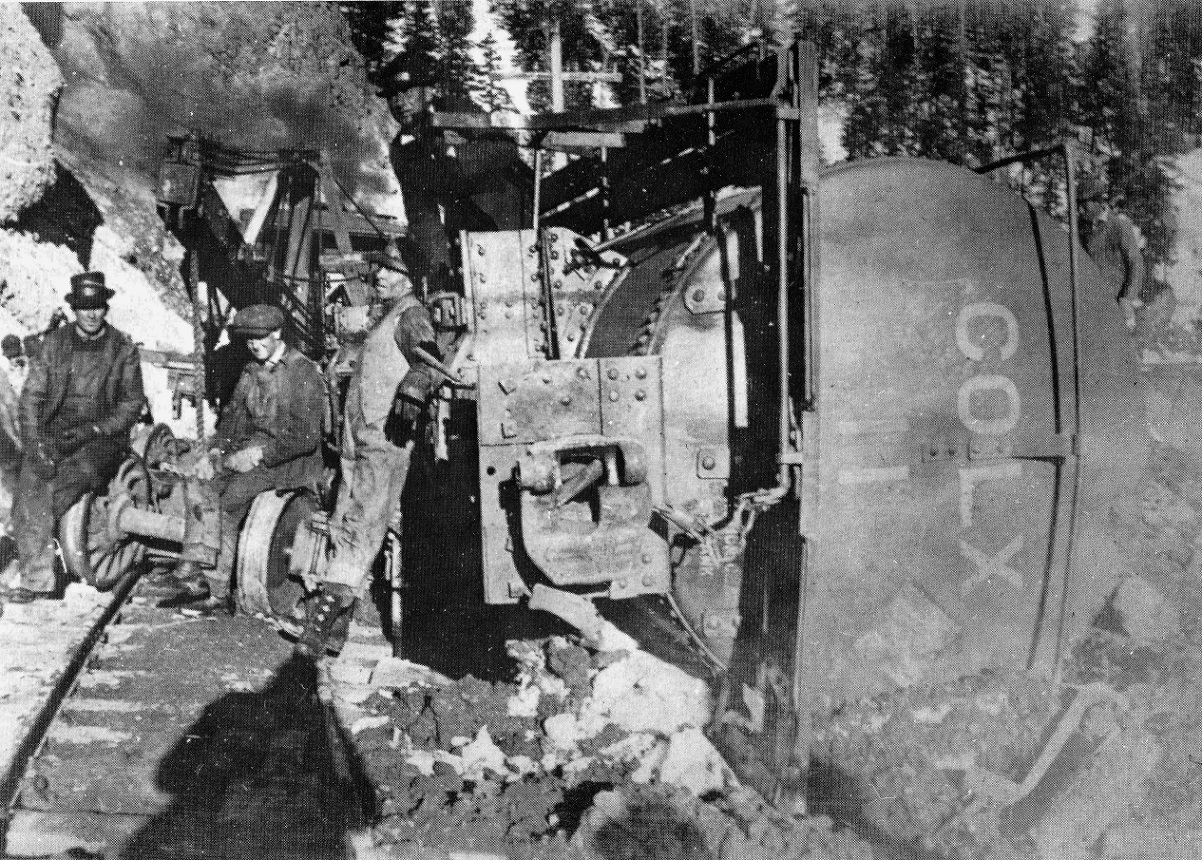

To me the photo of COLX 7 appears to be a smaller diameter tank than most other cars. I agree with you on the lettering, with a few differences: The "Continental Oil Co." on the side seems to be shorter in height than on the 1925 lettering, is centered vertically on the tank side, all letters are the same height (the first letters aren't taller), and the font (??) appears to be different, Gothic rather than Roman. Here is a photo of CONX 36 about 1925 in the then new 1925 lettering, courtesy of Doug Heitkamp:  As for the end lettering, it seemed pretty simple (both from Grandt's Narrow Gauge Pictorial, Volume IV, pages 128-9 :   The wreck photo of COLX 8 was on the north end of the RGS c1915; the wreck of COLX 11 was at Phantom Curve on the D&RG in April, 1919. As for the Standard Chemical tank car, Jim Vail published plans for the cars in the Gazette a while back, I'll try to find a reference. Evidently the standard gauge cars of this company were painted bright red. A guy named Regard Trosja built this model in Nn3 scale, I believe:

It is not clear to me what these cars carried; surely not radioactive materials in a liquid or slurry form? If so, how was it transported from Uravan, in the Paradox valley, to Placerville for transhipment? Perhaps the cars carried fuel for the mining enterprise.  Perhaps our resident expert on all things mining, Chris Walker, can opine.

Jim Courtney

Poulsbo, WA |

|

And you're in luck! An HOn3 kit for the car is available: http://www.narrowgaugecolorado.com/?name=Catalog&mode=i&item=000644.

Pricey, but with lettering included. And one of the tanks from the cars may have survived: http://www.drhs315.org/blog/drhs-railcars/1890s-tank-car-discovered/

Jim Courtney

Poulsbo, WA |

|

In reply to this post by Jim Courtney

Jim, taking a closer look at the lettering, I think you're right. I'm not really sure, though- I think the first letter that I can see is the "O" in CONTINENTAL, so I'm not sure about the height of the initial C. I can almost think I'm seeing the final o in Co. as a raised lower-case letter even with the top of the C, as is sometimes done in that contraction. But you may have a better version of the photo or better judgement, having looked at so many old pictures. As to the font, the end reporting mark is certainly a Gothic font, but I really can't tell about the side lettering.

As to the Standard Chemical cars, I've been doing some reading and I think they most likely carried gasoline in, not product out. Standard Chemical used a mechanical ore reduction process and then sent out their ore all the way to Pennsylvania in bags in boxcars where the chemical processing was done. There are photos of all this in the Oak Ridge (ORAU) site historical section. I'm guessing that gasoline was for air compressors for rock drills, which were coming into use in the 1910's, and Standard was an early adopter. Gasoline engines were also beginning to be used for mine hoists at that time, as an alternative to coal-fired steam engines. Given the very remote location of the mines at that time- the ore, in bags, was carried 60 miles to Placerville by burros- it would have been much easier to transport gasoline than coal back to the mines for power. but that's all guesswork on my part. Another possible use would be for power for the mechanical ore-crushing equipment, again instead of coal-steam power. John Greenly Ithaca NY

John Greenly

Lansing, NY |

|

In reply to this post by Jim Courtney

There was a post on NGDF recently about the recovery of the tank of one of the chemical tank cars.

|

|

In reply to this post by Jim Courtney

Aha! a kit, really. that almost makes it too easy! And it is pricey.

I forgot to say, I did some measuring of the COLX car in the photo and compared it with the car I have just built. The proportion of the height of the top of the tank to the height of the frame (both measured up from the rail) are, amazingly, identical within measurement error. So I don't think the tank is much smaller in diameter than CONX5 unless I have made my car frame too low, which I think is unlikely, as I got that from a very clear photo of the frame of CONX 6. I don't know whether or not that Primos tank that has been found could have been bought by Standard Chemical sometime later. From what I read, I didn't find that Standard Chemical used that mill, and I found no information that their ore was treated by a heat process in Colorado. The Standard Chemical car in the Trout kit picture does not have flat ends, as the Primos tank does- for what that's worth. Are the Trout Creek kits nicely done? I haven't seen their products. By the way, all this is rather off-topic for the C&S and I apologize for this in my first posted thread, but anyway: for anyone interested in how the uranium-vanadium-radium mining worked, this is a detailed reference: http://www.blm.gov/style/medialib/blm/co/field_offices/uncompahgre_field/documents/cultural_resource.Par.97850.File.dat/Guide%20to%20Assessing%20Historic%20Mining%20Resources%20Part%20I.pdf John

John Greenly

Lansing, NY |

|

Oops, I measured wrong- Jim, you're certainly right- that tank on COLX 7 is indeed much smaller than CONX 5 or 6. I was just looking at it again and realized that it's way lower than the reefer behind it. I re-measured my model and realized I did it wrong. My model's frame is in fact just the same as the photo of COLX 7, but the tank is not. That's okay for me, since I'm making COLX 6 (as best I can!).

John Greenly Ithaca, NY

John Greenly

Lansing, NY |

|

Thanks for joining us here in Roper's Dog House.

This, your first thread, has already been a lot of fun, and I've learned some new things. Jim

Jim Courtney

Poulsbo, WA |

|

Thanks, this is a lot of fun!

By the way, in studying photos to make my model of COLX 6 I came to the conclusion that the end saddles for the tank were right up against the end beams of the frame. This is different from the re-framed CONX 5, where the 30' flatcar is longer leaving some flooring between the end beam and the tank saddle. The tank I'm using (from a Taurus products kit for CONX 5) is about 24'3" long. I decided that the shorter configuration at the ends, plus the tank length, should determine my car length. Doing it that way, the car came out to be 27' long. If this is right, it could be that the original frame for this car came from a 27' flat or boxcar? John Greenly Ithaca, NY

John Greenly

Lansing, NY |

|

In reply to this post by John Greenly

That BLM document has a great history in it. I read it from start to finish (and it’s not short).

Thanks for posting the link, John. Cheers, Jeff. |

|

In reply to this post by Jim Courtney

Jim,

I'm not 100% certain but I would say that the Tankcars were used for chemicals such as Sulphuric Acid used in the milling process. Flotation Mills produced Concentrates which were usually shipped in sacks or drums as a dry product. Hence the photos of the Vanadium Mill showing strings of Boxcars not Tankcars. Mineral Belt V-II has a picture of a Millhand sacking Moly. at Climax pg 230.

UpSideDownC

in New Zealand |

|

In reply to this post by Jeff Young

Yes, I'm glad you liked it, I did too, never guessed that the BLM produced good things like that!

Since we are so far off-topic already, here's the Standard Chemical Co.story, complete with visit by Marie Curie, and lots about the radium business, in which they were a major player, as well as the later uranium- Manhattan project- story: http://www.canonsburgboro.com/History/Standard%20Chemical.htm Here's the photo album of Standard Chemical from the Oak Ridge archives: http://www.orau.org/ptp/collection/Miscellaneous/photoalbum/photoalbum.htm and here's the story of the part the RGS played in this whole business: http://riograndesouthern.com/RGSTechPages/atomic.htm Enjoy! John

John Greenly

Lansing, NY |

|

In reply to this post by Chris Walker

Right again Chris!

An here is a photo of all that sacked ore from the Paradox valley, ready to be loaded into boxcars:  http://www.orau.org/ptp/collection/Miscellaneous/photoalbum/orewaitingshipment.htm As the boxcars don't have the USSA grab irons yet, the photo is likely prior to 1915. That's quite the flat car load as well. According to the site the photo above, from an album, is a bit distorted due to chronic exposure to radium!

Jim Courtney

Poulsbo, WA |

|

Looks like the way we had to load a MF Super 92-only we had to use bridge planks to compensate for the amount of overhang of the tires.

|

|

In reply to this post by Chris Walker

Here's what I found:

The company’s mines were mainly in Paradox Valley in the southwest corner of Colorado in Montrose County. There, carnotite, a mineral containing vanadium, uranium, and radium, was mined, hand-sorted, and bagged in 75-pound sacks. High grade ore was shipped directly to the railhead. Lower grade ore was shipped to a concentrator erected some ten to forty miles distant from the mines. Sub-grade ore and waste rock was discarded. For every ton of milling ore that would be worked in Canonsburg, up to five tons of rock had to be removed from the mines. The company’s Paradox Valley operation employed about 250 persons. Paradox Valley was in a remote part of the state and getting the ore to Pennsylvania was a challenge. Supplies and equipment were hauled to the mines by burros. Ore was hauled from the mines to weigh stations the same way. After weighing, it was shipped by wagon to the concentrator. The concentrator, named Joe, Jr. for Flannery’s eldest son, used a wet grinding process. The concentrated uranium-bearing portion was collected as a filter cake, press dried, and, now a very fine powder, bagged. Wagons, and later trucks, using a former stagecoach road, carried the ore to Placerville, sixty-five miles away, where it was loaded into boxcars of the Denver & Rio Grande, a narrow gauge railroad. The boxcars were taken to Salida where the ore was transferred to standard gauge boxcars. The Pennsylvania Railroad delivered these cars via its Chartiers Valley branch (originally the Chartiers Railway Company) to the Standard Chemical Company siding at Canonsburg. this is quoted from the reference I gave above: http://www.canonsburgboro.com/History/Standard%20Chemical.htm I don't know anything about the chemistry, so I looked it up. Here's a neat pictorial description of Carnotite reduction: http://www.unitednuclear.com/extract.htm The key point seems to be that the Carnotite ore is very alkaline, so acid is not used in the initial concentration process. Here's a quote from the chemistry reference (this is describing an experiment you can do yourself, if you happen to have Carnotite handy!): Certain types of Uranium ore (Pitchblende, Uraninite) can be simply extracted with Nitric Acid. However, Carnotite and its associated matrix minerals are far too alkaline for Acid extraction and many of the minor Uranium ores will not dissolve in acid. Alkaline extraction is called for when dealing with Carnotite ore. To begin, you'll need 200 grams of powdered Uranium ore, 50 grams of Sodium Carbonate, 25 grams of Sodium Bicarbonate (use Arm & Hammer Baking Soda) and 1000 ml of water. So, that's why it looked to me that acid or other chemicals that would have been supplied as liquids in tank cars were probably not used on this ore in Colorado to concentrate it for shipment to Pennsylvania. John

John Greenly

Lansing, NY |

|

This post was updated on .

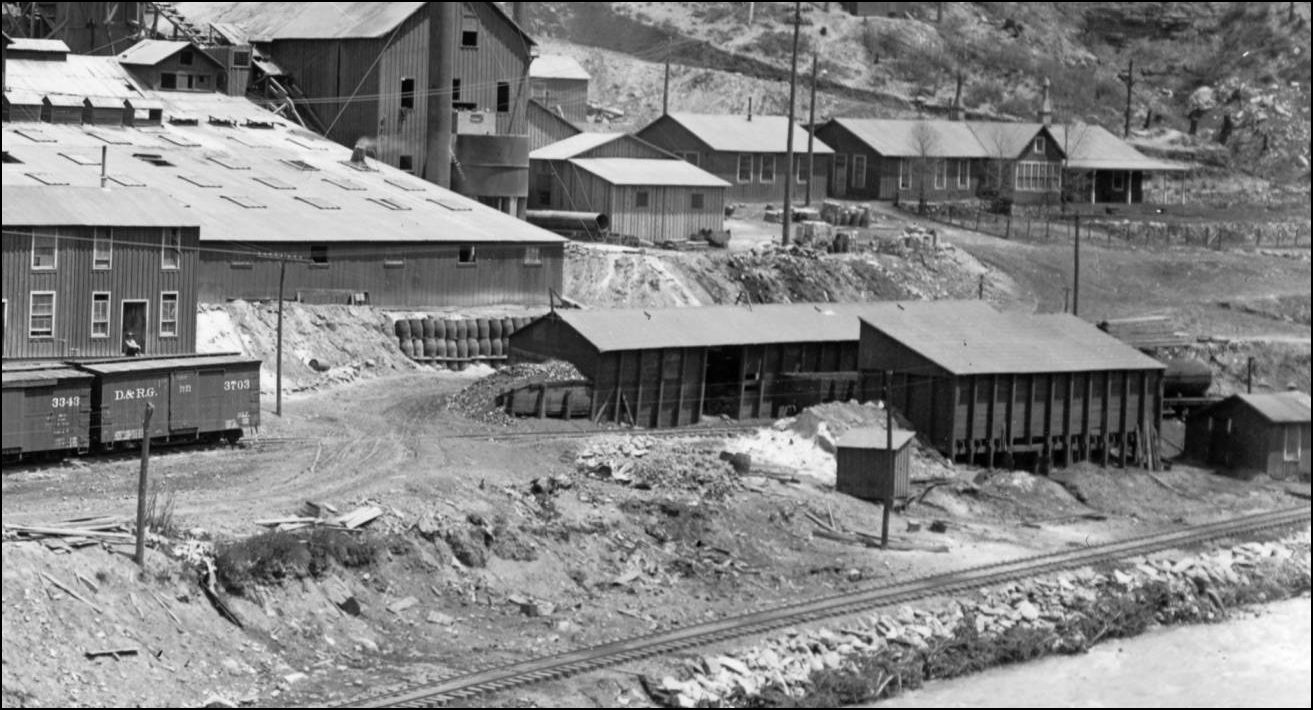

Newmire or Vanadium Mill, one tankcar, of which is visible, seen here. Notice that there is a large stack of Barrels also visible in the picture.

http://digital.denverlibrary.org/cdm/fullbrowser/collection/p15330coll22/id/14753/rv/singleitem/rec/2

UpSideDownC

in New Zealand |

|

In reply to this post by John Greenly

Yesterday I had a chance to use some more powerful search capabilities through my university library, and found that my post about carnotite processing was correct but irrelevant tao this case.

Standard Chemical was in the business of producing radium, and the uranium and vanadium in the ore were byproducts. There was no real market for Uranium yet, and there was much better ore available for vanadium production at the time. Radium is an extraordinarily rare element, and was worth over $100,000 a gram. Standard Chemical was the world's largest supplier. This is a unique case in terms of the processing of ore. Radium is a "daughter "element in the radioactive decay of uranium, so it is born and exists in uranium ore. But it is chemically distinct from uranium, so chemical extraction of the uranium (or vanadium) would lose the radium that is trapped in the raw ore particles. The ore was mechanically, not chemically, concentrated, by a grinding and filtering process in the mill called Joe, Jr. at the site that later became Uravan. That mill was repurposed by later operators. The concentrated ore was then shipped to Pennsylvania for the complex chemical treatment that extracted the radium. I found two references with more information, one by Joseph Flannery, the man who started and ran the company, and another in a book on radium production. Flannery wrote a report in the Thirteenth Biennial Report of the Bureau of Mines of the State of Colorado, for the Years 1913 and 1914, pp. 113–116. Here is part of it: "Carnotite, a uranyl vanadate occurring in southwestern Colo- rado and southeastern Utah, is the main source of the world’s supply of radium ore. For each 3,000,000 parts of uranium metal there is one part of radium metal in carnotite. Thus a carnotite with 1 per cent of uranium metal (1.18 per, cent U308) would carry one gram of radium element in 330 tons of ore. Radium, in its chemical properties is closely related to the alkaline earth metals, and it resembles the element barium so much that radium compounds are separated from the correspond- ing barium compounds only with the greatest difficulty." and, "The Standard Chemical Company is the largest producer of radium in the world. The output of radium salts produced by this company is three times greater than the aggregate output of all the rest of the radium-producers in the world. The Standard Chemical Company produces radium from carnotite from Colorado and Utah. The company owns many claims in these carnotite. areas, and mines its own ores. At pres- ent from six to ten tons of ore must be mined in order to secure one ton of shipping ore. After mining and sorting, the ore is packed by burro and wagons to the concentrator. After under- going a mechanical concentration, the ore concentrates are shipped by wagon to Placerville. The concentrator is sixty miles from Placerville, and the round trip by wagon takes a week. From Placerville the ore is shipped to the company’s reduction mill at Canonsburg, Pa., where the ore is treated. After the radium has been extracted from the ore, together with the barium, the radium- barium salt is sent to the Radium Research Laboratory in Pitts- burg, Pa., where it is subjected to a long process of concentra- tion, the radium being finally separated in the form of 60 to 75 per cent pure radium salt." The other reference I found was in a book: Mining and Selling Radium and Uranium by Roger F. Robison (Springer, 2014) pp 133-160 This book also describes the initial concentration in Colorado as a mechanical separation process that reduced the volume by up to a factor of four for the long and expensive trip to Pennsylvania. It was an inefficient process, and the ore waste left there was the beginning chapter of the long story of the gross radioactive contamination of the Uravan area. By the way, Flannery and his brother James were very ambitious, successful and interesting characters. They ran a separate company that was a very early producer of vanadium for steel, using very high-grade ore from Peru. They had another company that produced patented vanadium-steel staybolts for locomotives, and convinced Henry Ford to incorporate vanadium steel into the Model T. They formed the Standard Chemical company after their sister died of cancer, in the belief that radium treatment could have saved her. They were deeply involved in the radium craze that followed, touting radium as a panacea for all ills, even using it in fertilizer, which supposedly made crops grow faster! Don't know if anyone's interested in all this, but though I might as well pass it along, having tracked it down. John

John Greenly

Lansing, NY |

|

In reply to this post by Chris Walker

Chris, I happily defer to your and others' knowledge of mining and milling processes, of which I am mostly ignorant, though very interested to learn more about. I certainly didn't mean to claim that acid or other chemicals weren't used in general, but only in this unique case of Standard Chemical as I discovered and passed along in my other posts. I apologize for not giving references in my first post, I thought this wasn't of enough interest here to bother with, but I really appreciate that you all are careful to document your references for information and photos and I should have done that from the start. I still haven't found reference to what the Standard Chemical tank cars carried, but I'm quite convinced it was not acid or other processing chemicals. That was all done after the ore was shipped to Pennsylvania for the complicated processing to extract the radium.

That's a great photo you put up of the Primos Co. mill, lots of interesting details. It says the location was Vanadium, Colo., was it in fact producing vanadium? It almost looks as if those barrels are serving dual purpose as a retaining wall. thanks, John

John Greenly

Lansing, NY |

«

Return to C&Sng Discussion Forum

|

1 view|%1 views

| Free forum by Nabble | Edit this page |