What's on your workbench, July 2021?

What's on your workbench, July 2021?

|

Down Under clearly has a new project to show off: the goats must be busy. He chided me to show what is on my workbench. Well, not much:

I got some arch bar trucks from Paul Vaughn (now I forget what they are for... maybe a 3d printing of CONX 14?), a DB gon being built as a 4-board model because...well, Pat Student says they came over the hill to South Park. (Pat, we know you model the Evil Empire, but we still all enjoy your posts in these parts!), and the roof details for the roundhouse. I really need to finish the roundhouse and get it wired up and installed. The ponies are tiring of nights outdoors at elevation. Aside from that, the lawn requires weekly care, the tomatoes are screaming out of the ground and when I wasn't looking someone turned the economy back on--was that you Espee? Now I have to travel again!

Keith Hayes

Leadville in Sn3 |

Re: What's on your workbench, July 2021?

|

This post was updated on .

My regular workbench got so crowded, that I pulled out an old drawing board and set up shop at one end of the dining room table, next to the picture window with good lighting. It's worked out well as my wife had wrist surgery about 5 weeks ago, and still in a cast. She constantly needs me to do things for her: Help her open pill bottles, get dressed, put on her shoes, do the cooking, etc. (She still chews her own food but I have to cut it up for her . . .). The new work location makes me immediately accessible and I can chit-chat with her while I work on trains and she reads or watches TV.

As of this afternoon---  From left to right, top to bottom: 1) A 27 foot low side coal car ready for paint, 2) a batch of Michael York's Shapeways 14 ton truck prints, 3) a pair of 27 foot coal cars with all lettering just completed and ready for Michael's trucks, 4) an old Banta outfit car body kit that I built and painted years ago finally just got C&S lettering. On the lower right, Steve Guty has been experimenting with his own 3-D printer, making HO scale C&S 1910 tender bodies. He was kind enough to scale the file up to S scale, and sent me a test print to compare with my Overland C&S early #5 tenders. I've been making comparison measurements and owe him an email and photos of his print vs brass. Apologies for my tardiness, Steve.  I actually began cutting wood to begin the Breckenridge layout a couple of weeks ago, but had to stop and deal with climate change in my former shop, now railroad room. Up in the Pacific NW we've had a "heat event". I noticed that the room temp was varying from 63F at night and up to 85F during the afternoon, with the heat event just starting. I was lucky to score one of the last LG portable AC units in Kitsap County. With a couple of trips to Home Depot for a 6" dryer vent and connections, I was able to install the AC unit and vent it through a hole cut in an outside wall. Espee, Jeff Ramsey, and others that build in 1:1 scale, will be happy to know that my inside and outside 6" holes lined up pretty well, only 3/16" off, close enough to shove the dryer vent tube through. Our heat wave peaked last Monday at 107 degrees here in Poulsbo, unheard of in the 18 years we've lived here. Felt like I was back in Texas! The new unit worked its heart out but temp in the room still got up to 80F, although cooler than the house!

Jim Courtney

Poulsbo, WA |

Re: What's on your workbench, July 2021?

|

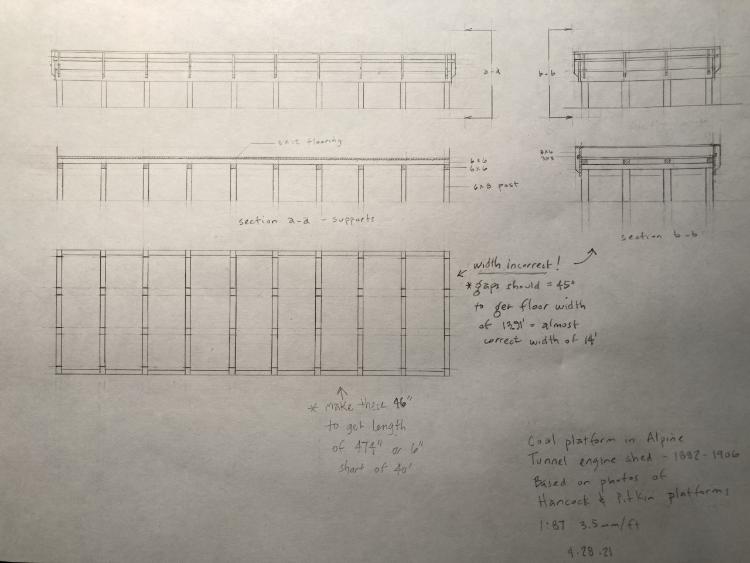

Finally getting to a project that I've been pondering for months: the coal bin inside the Alpine Tunnel from c1881 until the 1905 fire. All I know is the overall dimension, 14'x40', and where it was placed in the shed. No pictures, drawings, plans have been found, making this an interesting project.

Hancock and Pitkin bins are near identical in design and built within a year of the Tunnel's, presumably. Nathrop, the Tunnel, Pitkin and Gunnison are all listed with 14' width; Hancock is listed at 10' but I believe this might be an error. This all led me to a leap of faith that the Tunnel's original bin followed a similar design to all the other bins west of Buena Vista to Gunnison. The 1906 Tunnel coal bin replacement is structurally different and I quickly retreated from using it for information. There are maybe six photos of the Hancock and Pitkin bins and one of Nathrop's: side, end and inside. With all this in hand, and some thoughts on needed supports, I developed plans.  Errors showed quickly and adjustments made for the actual model. Plans also don't show intermediary stringer supports.  Second photo shows the foundational support structure glued together. Intermediary stringers and floor boards are stained and cut. Then time for jigs for the floor construction and the side support members. Not exactly sure why I decided to build this as my first scratchbuilt HOn3 model in 25 years but I'll chalk it up to insanity.

Dave Eggleston

Seattle, WA |

Re: What's on your workbench, July 2021?

|

In reply to this post by Keith Hayes

-An HO American Model Builders NKP caboose kit which I've modified to match the asymmetrical windows which most of the cars had, but none of the commercial models, and I'm building an interior for it based on a surviving car in that series which I've measured and photographed.

-Some N-scale Tichy workcars which my son needs help painting -One of Rick's CM reefers in HO -A Leadville Shops Tiffany in On3 -One of Bill's CC Porter kits -My laptop has been busy with drawing Oahu Railway locomotive parts and helping me work out the interior details to fabricate for that NKP caboose I have 3 work benches in my bedroom plus 3 in my basement...plus my laptop for 3D work. Michael |

Re: What's on your workbench, July 2021?

|

In reply to this post by Keith Hayes

I always enjoy seeing what others are doing, thank you for posting.

I have been posting updates for some time now about getting ready to install the wheel sets and journal box assemblies on 1008. Last time I showed the springs being installed, now our attention has turned to the journal boxes. A long time ago (well over a year) Stathi Pappas and crew at the C&T engine house in Antonio, CO poured and machined the babbitt for 1008’s brasses. They turned out perfectly and almost ready to install. The next part of the process is removing the overflow of the babbitt from surfaces where no babbitt is required, mostly on the ends. This was done by milling and scraping the the babbitt away. The machining and scraping was easy work because babbitt is not hard but more like lead mixed with some other stuff. All is now clean and we are ready for the next step, hopefully we will be getting some cooler weather soon (106 last week at my home) and we will get back to work.

|

«

Return to C&Sng Discussion Forum

|

1 view|%1 views

| Free forum by Nabble | Edit this page |