C&S Switch Chairs and Ball Throws...

123

123

Re: C&S Switch Chairs and Ball Throws...

|

Dave and all--I think Todd added a post mentioning Lee Kleidon's excellent analysis of stub switch geometry. And for those with some time, it is an excellent read. Fast Tracks does have what I will call a 'hack' to build a stub using their jig. I may try this at one point, but have not done so yet. Just be forewarned that the Fast Tracks jig uses the point switch geometry to make a stub, hence the hack. A noble effort but for some of the bean counters out there, it may have an unsatisfying result. (PS, Fast Tracks has some excellent free videos on how the frog works, etc., and I suggest watching those too). Plus, Jim was kind enough to make C&S turnout geometry folios available to us in the Files section.

Thanks, Jim (more photos of your abuilding layout and the models thereon, not just isolated switch parts, please) for the photos of the bridle bars in Delrin. Lots to learn here. When I posted my thoughts on 3d printed parts, I was imagining in my mind that these bars were about an inch wide, or about 1/64" (right?) to scale in S, so pretty skinny. The PBL parts look thicker than this, but not unreasonably so. Someone clearly thought through the issues when designing these. I don't have one, but can share that again Fast Tracks has some neat ideas regarding how to operate the live rails. So...to my question. I am thinking about the switch stands I want to place around the layout, and was thinking a harp or two would be nice. But...all my turnouts so far are point-style, and I realized that the live rails/ points function differently, which lead to the question. You all confirmed that as switches were changed out or modernized, this included the switch stand too (just imagine that cache of harps at 7th Street that got sold for scrap!!). So, I guess PBL switch stands will get mounted around my layout with a variety of targets, and hopefully I can make them operable so engineers can see the alignment of the switch before they get there. Maybe one option for me is to model a derail in Leadville with a harp. I don't recall derails being indicated on the track plan folio, though. Hmm. As the business books I am reading state, don't let great get in the way of good, and a group can get from good to great faster than one person.

Keith Hayes

Leadville in Sn3 |

Re: C&S Switch Chairs and Ball Throws...

|

More food for thought . . .

Until recently, powering stub turnouts in any scale usually involved using Switchmaster or Tortoise stall type switch motors, which require an mechanical stop for stub switches -- the stock rails provide a stop for the points of a conventional switch. My friend Dale Kreutzer has hand laid most all of his switches, using code 55 and code 40 rail exclusively; most are blade type conventional switches. With his Switchmaster machines he has found, over time, that the constant torque of the stalled switch machine tends to gradually deform the stock rails and bridles, with points every now and then popping loose. Small servo style motors were developed for the RC airplane hobby, I presume to control the flight surfaces of the aircraft wings and tail. There are now servo style commercial switch machines for the model railroad hobby. Dale has experimented with servo machines from Tam Valley Depot: http://www.tamvalleydepot.com/products/switchwrightmachine.html In Dale's own words: Although I left the stops in place for now (a holdover from using Switchmaster machines), you can adjust the servo to align properly without the stop. I like this because there is no tension on the bridle, which reduces the points coming loose events to zero. My plan is to replace all the switch machines eventually . . . There is a learning curve on using the controller that adjusts the servo position, but it works. The other thing I did is to continue using the DPDT switches on the fascia. Tam Valley has a push button system with LED, but I did not want to spend the extra money and reconfigure the fascia mounts. Dale has installed a servo style switch machine on the 3-way stub switch at the yard throat of his "Dolores". The stub rails will line up exactly for each of the three routes, every time. Using servo style machines would eliminated the need for any mechanical stops on the head tie chair., or at the two ends of the throw rod, as in the FastTracks scheme. The chair could then be a thin sheet of brass or nickel-silver, perhaps etched, just to secure the stubs of the diverging rails and allow the moving stub heads a smooth surface on which to slide. Or a one piece printed Shapeways head tie and bridles might then be sturdy enough to hold up under regular operation. ******** Sorry, Keith, but I really don't have a layout to show off, just a staging yard that I photograph on from time to time. Some of the tracks aren't even wired. It is not much more than an un-sceniced test track and a place to safely position a few structures that I've built.

Jim Courtney

Poulsbo, WA |

Re: C&S Switch Chairs and Ball Throws...

|

The Tam Valley site has a link to a you tube video showing a servo driven 3-way stub, with working harp switch stand, in HOn3: https://www.youtube.com/watch?v=jiFP_uJfOj8

Jeff will likely need at least one of these!

Jim Courtney

Poulsbo, WA |

Re: C&S Switch Chairs and Ball Throws...

|

In reply to this post by Jim Courtney

Jim,

Interesting information… years ago somewhere along the line I acquired a 3 way stub turnout control motor. It is sold by Cliff in Buena Vista IIRC. I think it uses a screw drive with some sort of stops too. I have not looked at it in years and even though I have built a couple of 3 way stubs in S scale I have never installed one on a layout. Lee Kleidon used a pair of switchmaster machines and some micro switches to control his three way stubs when I visited his layout years ago. HIs the only layout I ever recall visiting that I believe had entirely stub switches. Best, Todd

|

Re: C&S Switch Chairs and Ball Throws...

|

In reply to this post by Keith Hayes

Keith,

Both Rapido and also Proto87.com offer switch machines which can rotate a switch target and throw the turnout too. I just a few days ago got the Proto87 one to play with and I have not dug into it much yet. Like all Andy’s stuff it it is pretty well designed and fairly priced. But some assembly is required. I have not seen the Rapido in person but it looks interesting too from what I have seen of it online. It is more pricey but fully assembled I believe. I don’t recall wha tit offered as far as contacts to power a frog. I have thought that etched stainless steel, say 10-15 thousandths in thickness, could be etched as each end and part of the rod with each being inserted into a delrin or other plastic base to provide the insulation and provide the strength to the assembly as well as the middle piece of the bridle bar. If you are familiar with the Proto87 throws this is easier to envision I suppose. I have built a few of his HO turnouts for a friend and used the throw bars on some of my own Sn3 point turnouts. I have also played with making the bridles for Sn3 turnouts out of styrene pieces glued together. These can be built pretty easily and a wider and thicker styrene piece to for a T shape with the wide base forming the inverted top of the t and the bridle piece forming the leg of the T. Just a few more thoughts and ideas I have played around with over the years. Best, Todd

|

Re: C&S Switch Chairs and Ball Throws...

|

In reply to this post by Jim Courtney

Neat stuff Jim, thanks for sharing!!!

Todd

|

Re: C&S Switch Chairs and Ball Throws...

|

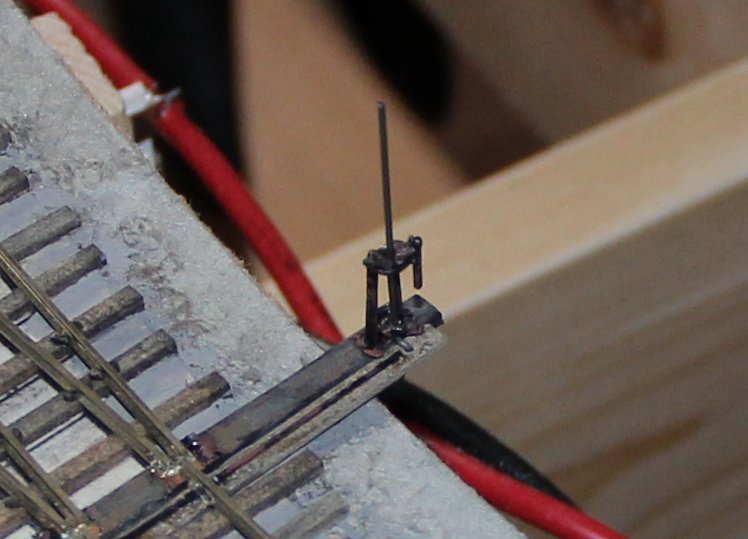

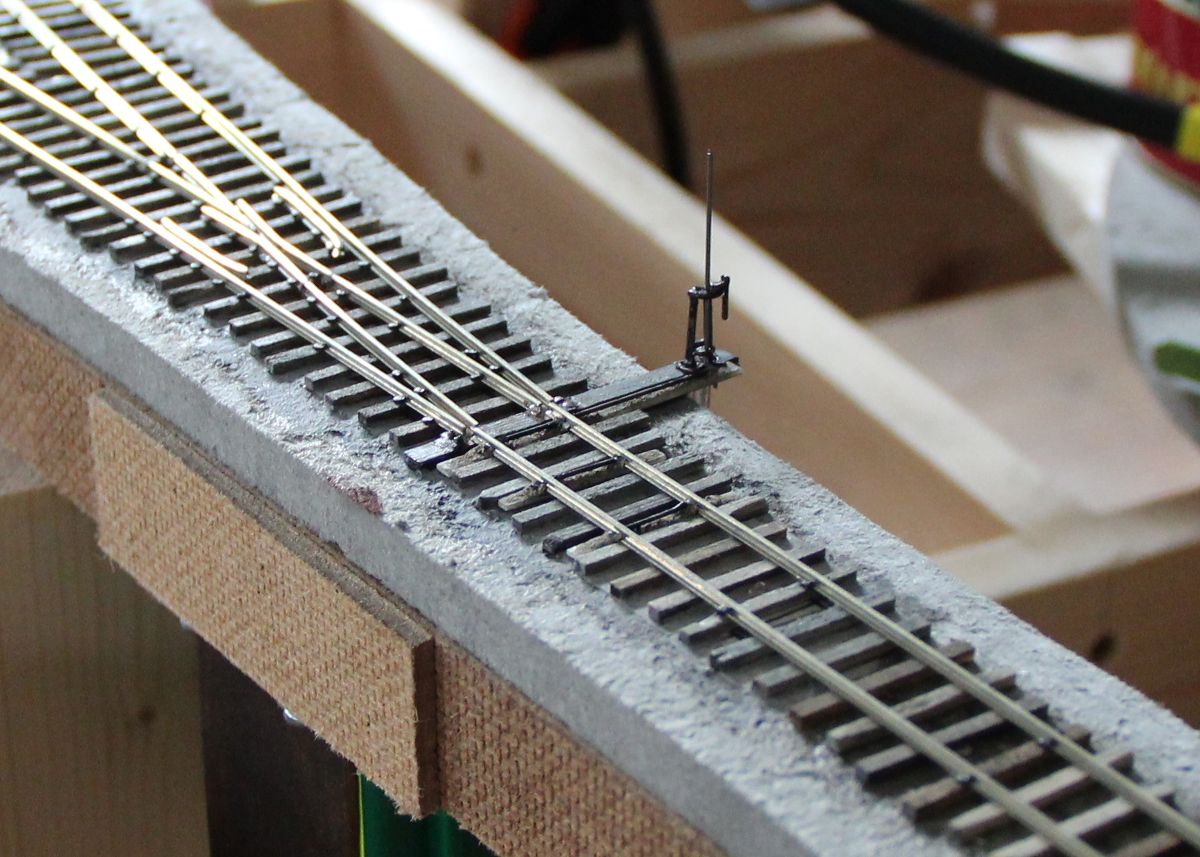

You guys have probably already seen these, but here's how I automated my rotary switch stands:

In the above picture you can see the throw bar "carrier", which is a thin pc-board tie disguised with dirt. The throw bar on top is a styrene rod. The "carrier" also has a hole drilled in it at the end for the crank bent in the end of the switch machine target rod. Here's the same switch a month or two later:  The bridle rods are done the same way:  It's a bit fiddly in HO to get it working right, but I imagine it would be easier in S. Cheers, Jeff. |

Re: C&S Switch Chairs and Ball Throws...

|

This post was updated on .

Jeff,

does your drop-handle rotate as well or just the target mast? I imagine this to be cast in one place and one of those compromises modellers have to make. Personally I would have made the Bridle ties the same size and take the place of the adjacent tie you have alongside with the actual Bridle a little to the side of the tie. That would then give no deviation in the sight line of ties. You certainly have the ground cover truly mastered.

UpSideDownC

in New Zealand |

Re: C&S Switch Chairs and Ball Throws...

|

Chris, the drop handle is actually a separate casting, and I suppose could be glued to the target mast. But I just glue it to the top plate and leave it non-functional.

Cheers, Jeff. [Edit: fixed spelling. Chris isn't really spelled "Jim".] |

Re: C&S Switch Chairs and Ball Throws...

|

In reply to this post by Chris Walker

Back at Como we need numerous 2 way and 3 way stub chairs. There are many examples of cast iron D&RG (RGS) stub chairs surviving but does anyone know of any C&S design chairs around, like the built-up forged and rivited ones that are seen in the file section of this forum? What design is seen on top of Kenosha Pass today which are forged and rivited but the stock and diverging rails are stayed with a slot that afixes to the web of those rails?

|

Re: C&S Switch Chairs and Ball Throws...

|

Yes Jeff, if it was riveted then it was C&S, a hold over from the UP I think since the Chair at Greymont shows the riveted construction.

more see http://c-sng-discussion-forum.41377.n7.nabble.com/ICC-map-abbreviations-tp2242p2294.html Chances of you finding extant examples will be interesting, surely you can find a shop that can replicate a few for you.

UpSideDownC

in New Zealand |

Re: C&S Switch Chairs and Ball Throws...

|

A few years back I got some stuff from TamValleyDepot.com for my 3 way stub turnouts.

A Dual 3 way Servo Decoder, Miniature Servo, and Hex Frog Juicer. I did use one of the Frog Juicers and it works great. One lead for a frog. And two leads linked together for a wye. I have not even opened the bag for the other components. My layout has three 3 way stub turnouts. All three are not functioning and are an electrical mess. And I just have the head rails spiked down for now. Soon I am going to rework them and try out the Tam Valley stuff. I will start a new thread here when I do. Let you all know how it works out.

|

|

Don,

I'm curious about your experiences with the Tam Valley stuff, since I'm planning on building at least one HOn3 3-way stub switch. During my research on how to control that thing I also stumbled across Geoff Bunza's work (e.g. http://model-railroad-hobbyist.com/node/24316) about Arduino based DCC decoders. I actually used his schematics to build 2 staging area controllers with tortoise driven turnout controls and power routing and reversing, switchable via DCC turnout commands. It was fairly easy (with my programming background...) to get started on the Arduino platform, they are running my own programs based on DCC libraries. It shouldn't be to hard to come up with a servo based 3-way stub controller that also drives the frog polarity via relays. Alex |

Re: C&S Switch Chairs and Ball Throws...

|

Administrator

|

In reply to this post by Don Gustavson II

Hi Don,

Here is a link to my first experience installing the Tam Valley devices: Turnout Control While I am sure these work great for regular point turnouts, there are a couple of factors which make using these servos for stub turnouts frustrating. The combination of temperature related expansion and contraction of the rail itself, and humidity related expansion and contraction of the Homosote roadbed. These factors require that the servos be re-calibrated before anytime I want to operate the layout. I eventually installed spikes to the outer rail as stopping posts for the servo to stall out against. Getting the center route of my only three-way to align every time is a crap shoot. If I were to do it over, I'd go back to using a Tortoise for stub turnouts. My biggest suggestion for using the servos would be to mount the Dual Three-Way controller in an easy location where you can regularly view the alignment of the rails while working the buttons. Unfortunately, Tam Valley does not offer their remote device for the Dual Three-Way. |

Re: C&S Switch Chairs and Ball Throws...

|

In reply to this post by Jim Courtney

I did the tooling for the Sn3 stub switch back in the 90s for Building & Structure Company. I worked (and am working here again) at Micro Engineering. I had just started modeling in S and John Kalin & Pete Smith asked if I would do some turnouts. My interest was in early 1900 narrow gauge so a stub in code 55 sounded good. Later Building & Structure was sold to Banta who promptly sold the track to PBL. The track and turnouts are still made for PBL by Micro. I only installed a few stubs before switching to On30. Of course I had to have track for my layout, hence the Code 70 On30 track.

Rich |

Re: C&S Switch Chairs and Ball Throws...

|

Rich,

Thanks for sharing this history. I knew PBL ended up with the track but I didn’t remember the details. You lived it in some part which is cool. I know there are a lot of people who like and use On30. But I have always thought it was a mistake for the wrong reason. That reason being the use of HO track in my view. Perhaps there are other reasons but I will always wonder where On3 might be if those resources were invested in that instead of On30. Todd

|

Re: C&S (and others) Groundthrows, Como Ball Throw and Blades...

|

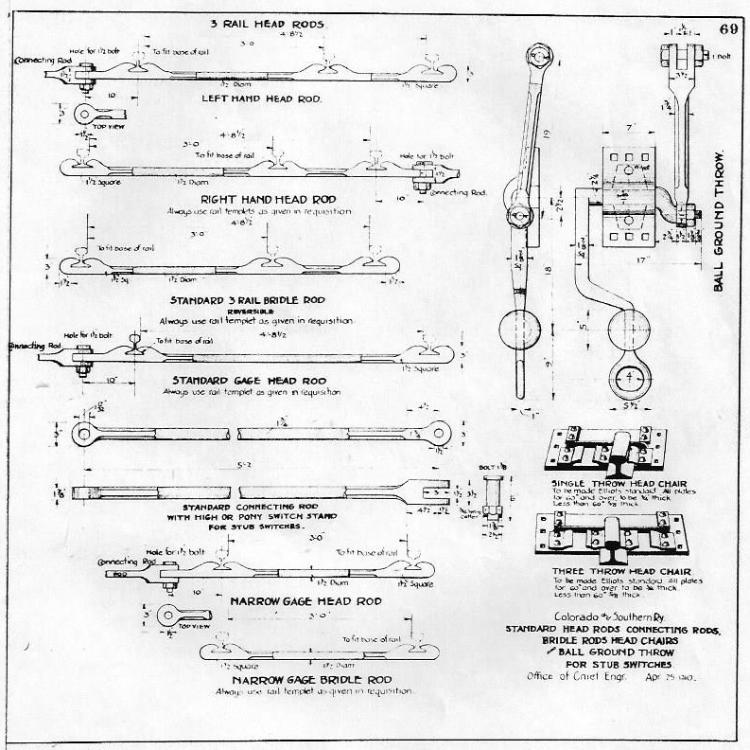

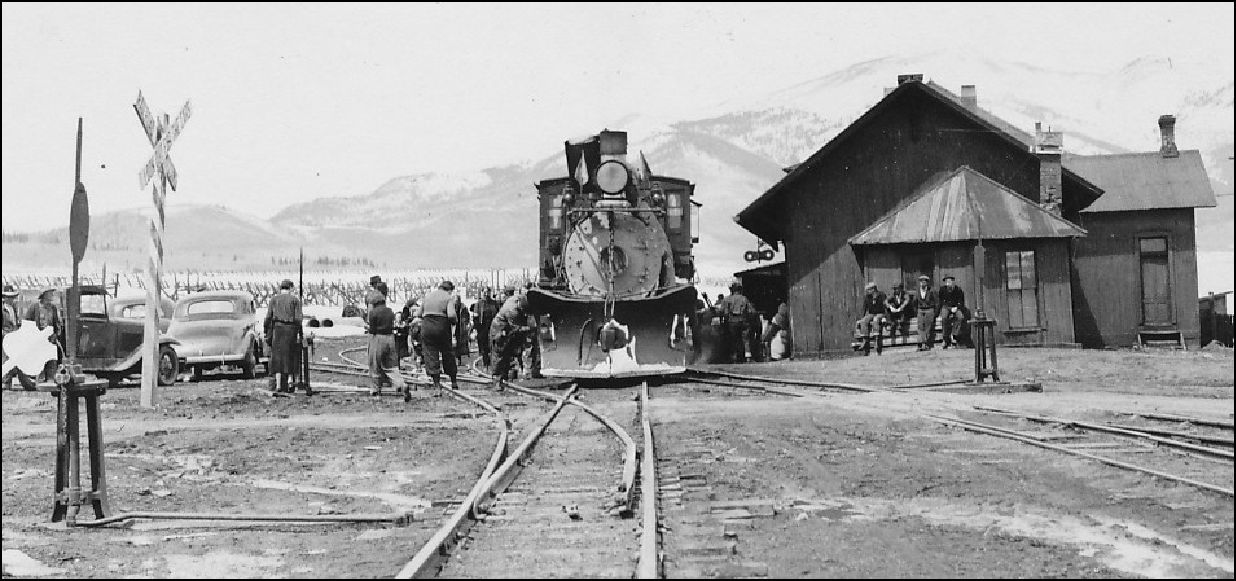

In reply to this post by Jeff Young

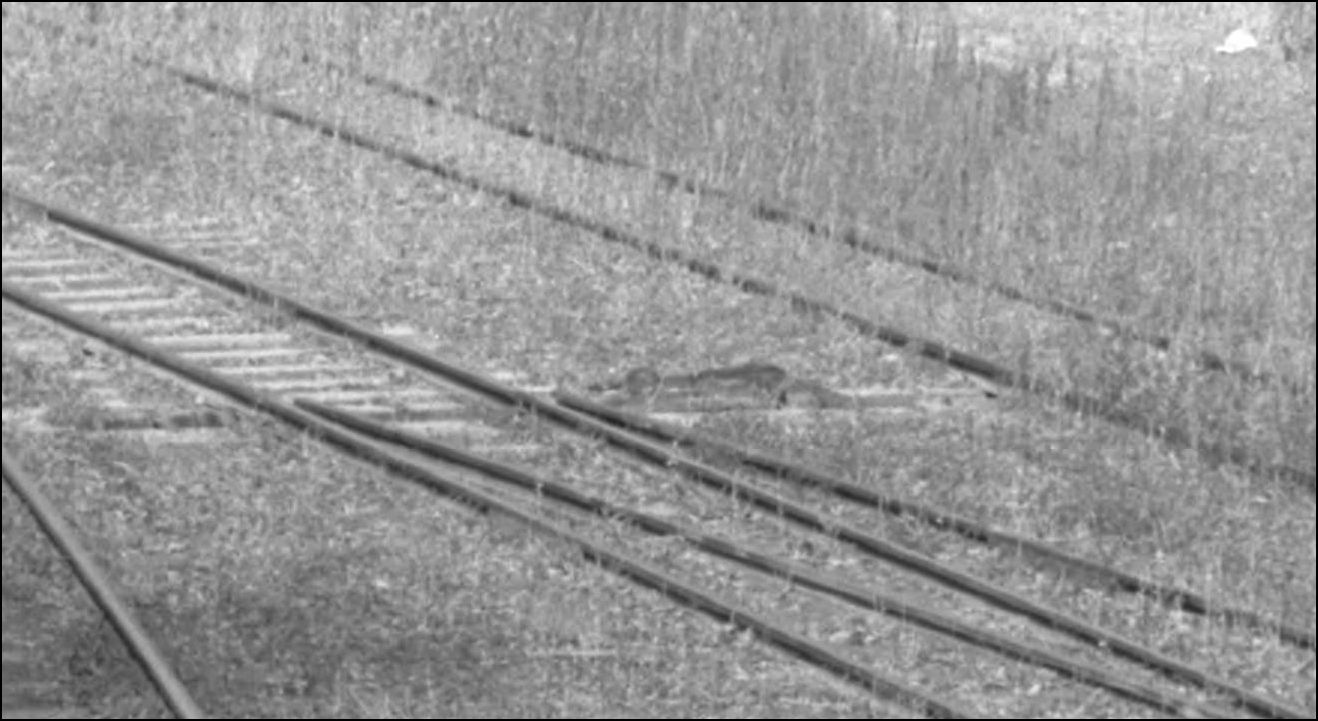

Jeff, I made that comment in a fashion based on evolution, and in that vein applied to real railroads, not re-creations, restorations, museum, tourist or backyard operations since the 15" Redwood Valley RR in California has harps actuating blades. I've seen steam locos with old brake valves, #4 and #6 and refitted with new brake valves, 26L. I've driven diesels that were built with old #4 valves, newer diesels built with 6SL and re-fitted with 26L, and even newer diesels built with 26L. But I never drove, nor saw a diesel fitted with a #4 in place of the original 26L. I wisely assume that to be the case with the Harp controlled stub switches which were as we know, refitted with Buda/Elliot rotary stands and bladed switches fitted with Buda/Elliot but I doubt very much the regression to Harps on blades. I'd be delighted to see evidence to the contrary though. Now to a little treatise on the Groundthrows. These were installed to indicate the direction of switch by visual location of the placement of the weight, with a possible couple of exceptions, maybe mis-installations such as the Gilpin at Blackhawk. The WSLCo had a changeable handle to re-orientate the crank throw i.e. the Bladed switch being at opposites to the Stub switch in lever position and can be placed either side of the switch. The C&S Ball version is strictly for stubs as the crank is in the same hemisphere as the handle/lever, as does the D&RGW version.  C&Sn3 files http://coloradosouthern.blogspot.co.nz/p/f.html Cimarron, D&RGW. RR-1792  http://digital.denverlibrary.org/cdm/fullbrowser/collection/p15330coll22/id/79857/rv/singleitem/rec/19 Toulumne, West Side Lumber Co.  https://upload.wikimedia.org/wikipedia/commons/f/f4/Westside_Lumber_Engine_Shed.jpg Blackhawk, Gilpin Tramway Co. Note that the Handle is placed nearest the rail same as the above D&RGW but the rails are in the opposite position. Z-187  http://digital.denverlibrary.org/cdm/fullbrowser/collection/p15330coll22/id/10793/rv/singleitem/rec/1 Finally the C&S content  Como stub (partially dismantled) with C&S Ball weight groundthrow, this switch had a Harp, see p37 C&S Highline Memories, then at the time of the Valuation train, had no throw whatsoever. see pg83 Mineral Belt II X-7517  http://digital.denverlibrary.org/cdm/fullbrowser/collection/p15330coll22/id/5150/rv/singleitem/rec/69 And now for those Bladed switches that Robert asked about....  The most noticeable Bladed switch at Como. No Braces fitted outside the switchpoints rails here.  R.B.Jackson photo The lesser noticeable Bladed switch at Como, note the Braces on this rails of switchpoint...the stubswitch replaced after 1929 R.B.Jackson photo was taken, see pg86 C&Sng Z-6055  http://digital.denverlibrary.org/cdm/fullbrowser/collection/p15330coll22/id/72086/rv/singleitem/rec/11

UpSideDownC

in New Zealand |

Re: C&S Switch Chairs and Ball Throws...

|

In reply to this post by Jim Courtney

Jim you can make a pretty decent number 8 stub using the straight and one side of Lee Kleidon's 3 way stub turnout. I believe the larger or longer plan is a number 8 or 8.5 frogs and a number 6 for the short frog in the center. I think those are included in the stub files in the Files section...but I didn't verify tonight. If not I can scan and send to you.

Todd |

Re: C&S Switch Chairs and Ball Throws...

|

In reply to this post by Chris Walker

A talented Blacksmith might be able to make them if they have the ability to heat metal that size.

Todd |

Re: C&S Switch Chairs and Ball Throws...

|

You guys need to look at what Randy Lee has at Grizzy Mountain on his web site. He has a servo power device specific for stub turnout. He has three short video's showing how it work's. Check it out.

John McCutcheon |

«

Return to C&Sng Discussion Forum

|

1 view|%1 views

| Free forum by Nabble | Edit this page |