C&S Switch Chairs and Ball Throws...

123

123

C&S Switch Chairs and Ball Throws...

|

Hey Gang,

For a while I have been pretty quiet on this list. Just busy with a son's wedding and racing season for my other son the past few months. I am now trying to get back to it a bit. I have for many years though about the building of stub switches and the details surrounding them. I have studied the stub switches at the CRRM on several occasions and documented them with photos. I have studied prototype photos where they are available in the various books and photos. I have mulled over the drawings of the C&S Head Chairs, Ball Throws and Throw Rods/ Bridle Bars in the Files section here. Now I am at the point of inquiring as to the interest in having these parts made available for C&S modelers. I am interested in S and O scale primarily and due to small size am not sure this detail would be easily possible or functional in HO scale. But I certainly would like to discuss the merits and demerits of this in any scale. The Head Chair is pretty straightforward and seems like it could be modeled fairly easily. The question in my mind comes more in trying to make these parts more easily and readily available to modelers. I am thinking along two lines. First would be to model the parts with a solid modeling tool such as SketchUp and print the parts as 3D parts at Shapeways or some other printer. The other option I am interested in is possibly having these parts made as brass castings. This would require masters be made and then the castings produced. Both options have pros and cons. I am not sure how well the 3D printed parts would hold up in actual functional use. It might be fine or it might fail. some of the resins are quite strong and some rather brittle in small cross section. The brass would certainly perhaps the preferred solution but I am not that familiar with the process to produce such parts in any quantity. Brass would also allow the base of the rail to be soldered to the casting for a solid connection. I am not sure that this soldering is a definite requirement for success though. With the 3D modeling approach I have also though of just modeling the complete Head Chair parts on a tie and therefore giving a much more robust and easily usable product in the weaker material. Rails could be glued in place in the Head Chair with either ACC or 5 minute epoxy. The bridle parts are a more unique challenge and most possible in O scale it seems. Brass would seem to be the logical choice but the bridle bars have the electrical gap issues to be addressed. An engineering plastic might be the optimum choice but that would require hard tooling and likely be expensive. What are your thoughts on this set of parts and your interest? I am aware that Grandt already makes the bridle for code 100 rail in O scale too. That may be good enough for most people. The C&S Ball Throw is the last item of interest in this discussion. I have long like the idea of having large scale throws for throwing turnouts in S scale and now the same interest in O scale. I would see these as 1:20.3 or 1/2' scale throws but that is not set in stone. In O scale it might be feasible to cast these in brass and actually do them to scale and make them functional on the layout itself. In the larger scale they could be cast in brass or white metal or even resin. They could also be modeled and produced via 3D printing and solid modeling. To me it would be cool to operate the switches on a layout using prototypical throws. But it is certainly not a necessity. Lets see what thoughts the rest of the forum has on this topic. I look forward to your input. Best, Todd Ferguson |

Re: C&S Switch Chairs and Ball Throws...

|

Todd, my Spidey sense tells me the fine detail plastic from Shapeways is not rugged enough to withstand continued use, especially with larger rail (code 70 up).

Brass or a lost was casting have conductivity issues unless your pike is detail. That leaves an engineering plastic, like Delton. Again I suspect the scale part is too fine to withstand continued operation. But heck, I am just kibbitzing. Do it and fail fast to come up with some groovy hybrid solution that I am not thinking of, like brass at the rail grips wit a plastic bridge...

Keith Hayes

Leadville in Sn3 |

Re: C&S Switch Chairs and Ball Throws...

|

FWIW way back when I was in H0n3 I used a thinned PC tie with soldered in spikeheads to make the Throwbridles forgoing the spacer bridles. These were even better when I upscaled to 0n3 and beyond. Whether that construction would be worthwhile in retail as opposed to home make do I don't know. At that time there was no other solution available, going battery powered was the answer.

Funny how this subject has come up while I am making 4 Groundthrows for my Tramway  with proper Bridles with proper Bridles

UpSideDownC

in New Zealand |

Re: C&S Switch Chairs and Ball Throws...

|

In reply to this post by Keith Hayes

Keith,

Are you talking conductivity issues in the Bridles or in the Chairs. I agree the Bridles are a problem if solid metal unless you are running battery power. Battery of course may be an option in O and perhaps even S as time goes by. I wish there were some dimensions on the Chair drawings. I recall that the center to center spacing of the rails is 5” on the prototype stubs…at least on the RGS. These are tiny parts even in O scale I guess. Perhaps too small to even matter to most modelers. Todd

|

|

In reply to this post by Todd A Ferguson

I haven't tried using them, but note that Trout Creek Engineering offers HOn3 bridle bars: http://www.troutcreekeng.com/bkho.html (scroll way down for 'Other Items'). I was thinking I'd have do something similar to a PC tie to do this in HO, but will order some of these and see what they are like.

There are companies that do metal 3D printing, but, as noted, only good if conductivity between rails is not a problem. BTW, did anyone else notice that the most recent issue of Model Railroader focusing on track and turnouts managed to never mention the existence of stub switches anywhere in the issue? Although they had an article on building single-point traction switches, which are even a greater oddity? |

Re: C&S Switch Chairs and Ball Throws...

|

Interesting find, Steve. Post a picture of the Simpson bridle bars when you get them; I’m very curious to see what they’re like.

Todd, for chairs I’m just soldering a small piece of brass with a couple of NBWs to the outside of the rails. It adds enough “visual noise” in HO scale to suggest a chair. Cheers, Jeff. |

Re: C&S Switch Chairs and Ball Throws...

|

In reply to this post by SteveG

Not many people modeling stub turnouts other than some narrow gaugers and a very few 19th century trunk line modelers I expect. They were outlawed on the trunk lines by the early 1900s IIRC. Lee’s information / clinic on them gives a lot of information on how different they are from a point turnout geometry wise. Many people think that you just remove the points and can turn it into a stub turnout pretty easily. That can be done but the geometry is not correct. But many people don’t know or don’t care to model it that way.

Todd

|

Re: C&S Switch Chairs and Ball Throws...

|

This post was updated on .

In reply to this post by Todd A Ferguson

Todd,

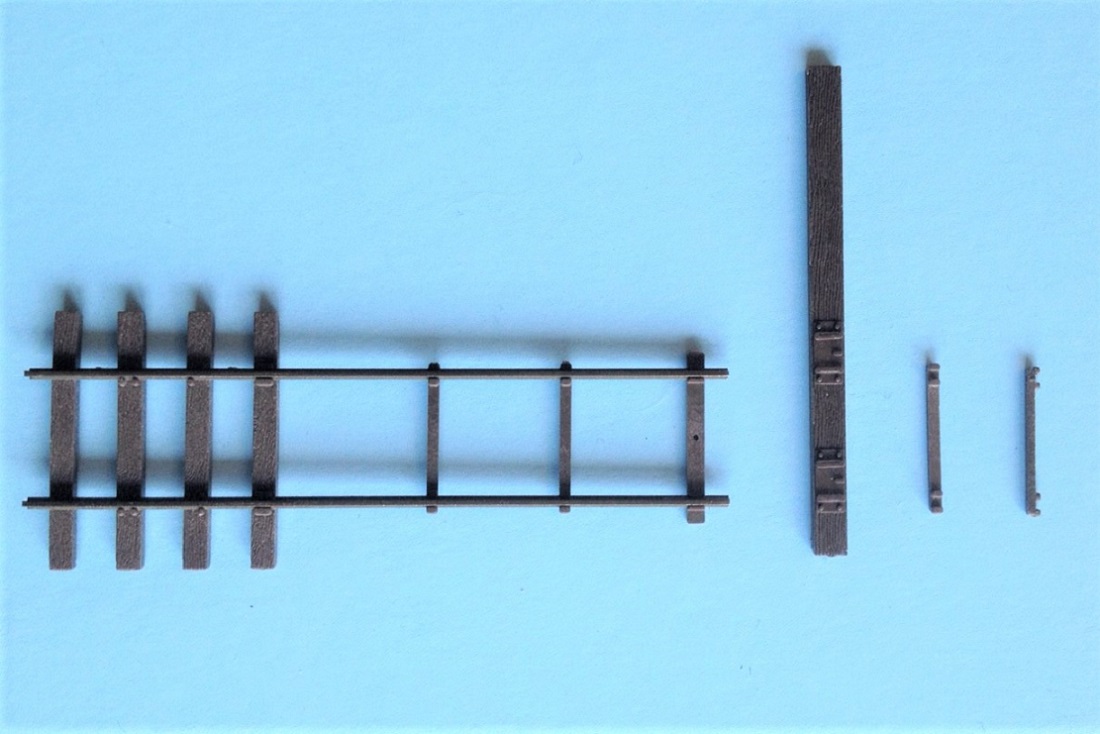

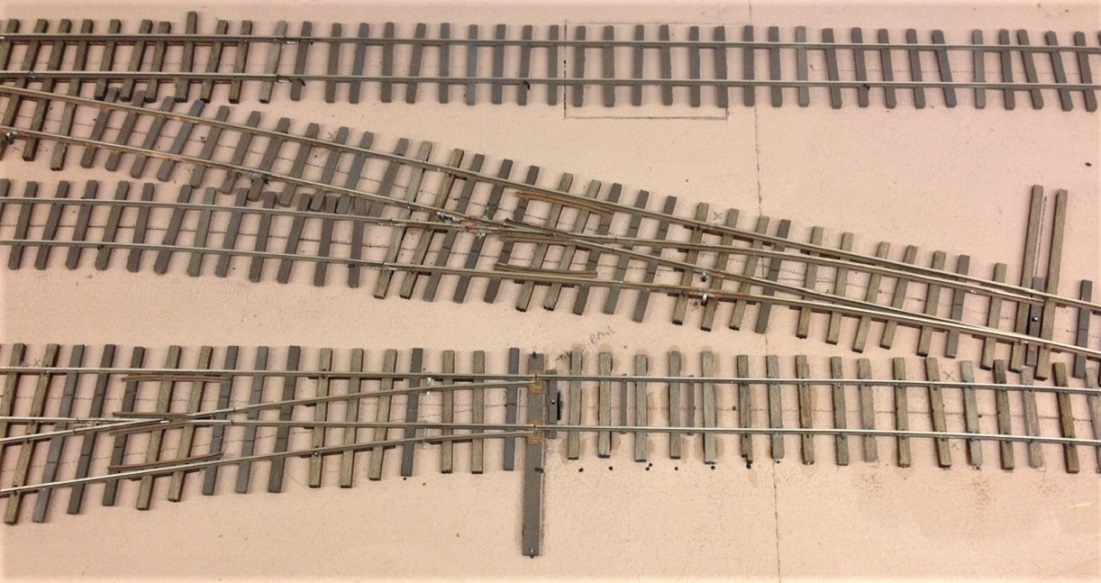

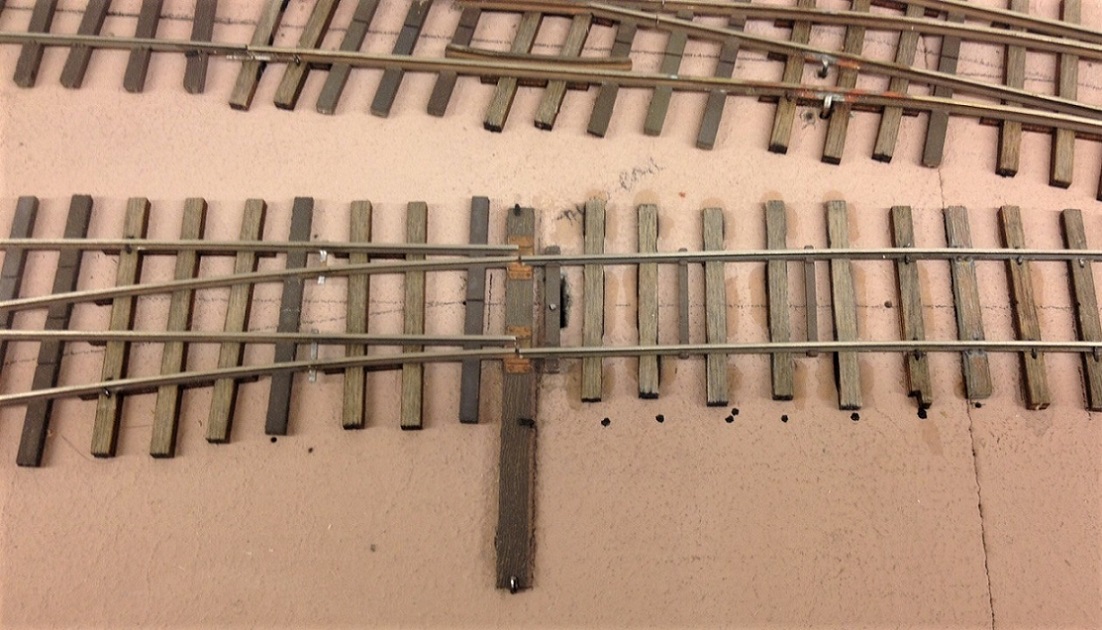

For Sn3 modeling purposes, the items that you describe designing and producing seem to be a reinvention of an existing wheel. Problem is that the existing wheel is not readily available. For many years, PBL has marketed Sn3 code 55 stub switches. The actual manufacturer is either Tomalco or MicroEngineering, perhaps both, sequentially. The switch comes with a separate head tie made out of Delrin, with rail chairs integrally cast into the part; also included is a short section of two rails with a single throw bar and two bridle bars which easily slide onto code 55 rail:  I don't particularly care for the stub switch itself, with its neat, squared Delrin switch ties, so I've used just the PBL parts in the photo with #6 turnouts built up in a FastTracks jig. I cut the rails off at the point end, and file them so the distance between the stock and diverging rails are the same distance apart as on the PBL switch, so they will fit with the outside edges of the rails snug in the cast-on chairs. I then use stained FastTracks laser cut ties or individual ties, and try to paint and stain the PCB ties to match (not always convincingly):  The cast Delrin chairs are very sturdy and the cast "arms" provide a perfect stop for Tortoise switch machines:  The throw bar and bridle bars are also very sturdy and keep the moving stub rails in perfect gauge. I've approached PBL a couple of times about purchasing just the parts I need (head tie/chairs, throw bar, bridle bars) but have never received a response. I got lucky at the last Seattle Sn3 symposium and purchased a batch of salvaged PBL stub rail assemblies for parts, from a gentleman who had dismantled his layout:  So I now have enough throw bars and bridle bars for seven more turnouts, but need 6 more head ties. Perhaps several of us interested Sn3 modelers could approach PBL (or their manufacturer) about purchasing the individual parts. Frankly, I'd prefer metal chairs to mount on wood head ties. Just a thought: How about etching the chairs in nickle silver, rather than casting them in brass? Bill Meredith has entire locomotive etching sets in nickel silver. They would be easy to solder to the bottom of the paired stock and diverging rails, tying them together electrically. I'm not sure, but I think the etching could be deep enough to etch in the "arms" of each chair as stops. The paired chairs could be then epoxied down to the wood head tie. Better yet paired square holes could be etched into each side of the chairs, like tie plates, to allow the chairs to be spiked into the wood head tie with micro spikes.

Jim Courtney

Poulsbo, WA |

Re: C&S Switch Chairs and Ball Throws...

|

Hey Jim,

Wow, you put some effort into your contribution to this topic! I believe I have one of the Tomalco Stub turnouts in my collection. I recall buying one to tryout years ago but I never opened the package I don't think. I got sort of hung up on longer more prototypical turnouts in the 8 1/2 to 9 range. I even had Fasttracks custom design me a jig for Sn3 number 9 turnouts. I think they then offer it in other scales as it is fairly easy to rework or even parameterize the CAD work. So, the number 6 stub turnout in the end just was sharper than what I was looking for at the time. I will have to dig it out and checkout the parts you are showing and using. They look like nice parts for sure. Once I learned from Lee Kleidon about the geometry of stub turnouts I also realized that the geometry of the Tomalco Stub was not quite right. Again that may not matter if one is happy with the number 6 frog and the turnouts function good. I believe that the Tomalco Sn3 track was sort of inherited by PBL years ago when the Tomalco Standard gauge track line was purchased by a man here in North Carolina. I believe Bill Peter told me that he didn't want the Sn3 track and so PBL sort of reluctantly took it on since they are "The Source for Sn3". If that is the case and they control production it might be possible to get the plastic parts as separate items at some time. The issue I would see is that they probably rarely actually load up the molds and make stub turnouts. They may also outsource this to someone else to make the turnouts who is set up for that business and more efficient at it. I really doubt that they sell more than a handful of stub turnouts each year. When I visited PBL about 18 years ago in Ukiah it was about the time that the flangers had just arrived and Bill was taking advertising photos while I was there. He showed me the stock of the Eel River Beer Cars that they had just produced and said that they sold over 10,000 of the HO beer cars the first year with only a couple roads and undecorated. He said that they were lucky to sell 1,000 of the Sn3 cars across the entire line of Sn3 car kits in a year. His comment was now you know why people make stuff for the HO market. So, to offer the parts as a separate item for the stub turnouts sort of would be cutting into the small sales of complete turnouts for PBL. And even if they sold the parts for lets say $10 a set if they only sold 100 or even 200 sets that is not much revenue. I know some people think that they charge too much for their brass locomotives. But I always looked at it as you pay a premium for the locomotives and other brass items and that money subsidizes the development of the freight car kits, and now RTR cars perhaps. I think Billy thought the Hybrid K-27s were going to be a great thing for the Sn3 world. But I think what he didn't realize was that he was devaluing the Brass K-27s that I and many others paid a lot of money for over the years. So, it is a double-edged proposition. Recently they announced they are planning a Hybrid C-19 which would sort of do the same thing perhaps. There seems to be a glut in the Sn3 market as the modelers get older or change and more items come on the used market. Yet much of what has been made will probably not ever be made again brass wise. That is why I resist parting with Sn3 brass pieces that I have. Once you get ride of them it would be very hard to get them back again I fear. But I digress... So, on my visit I also saw the test shots for the enclosed vestibule passenger cars. Yet nearly 20 years later they have not become complete kits not come to market. Same with the Overland gondolas for C&S. I don't think those have formally been put back into production either. Jimmy was also working on track details probably 10 or more years ago. But the only think that came out in the past 20 years was the switch stand kit. Maybe it didn't sell well enough to make it worth doing more or they got diverted onto other projects with more potential. Who knows but the folks at PBL. Billy always said his people like to Eat!!! Getting Billy to put DCC in his models was a major change...he and I had that discussion several times too. He always called it the re-issue of the old GE Astrak system from the 60s! He spent a ton of money on his PBL Foreground sound system and that pretty much died because of Bob Longnecker getting ill and the rise of DCC. It was a nice product but was never going to keep pace with the advances of DCC sound. I had both in 1996 and it was clear where the future was going to be. So, I appreciate your input and I will have to pull my stub out and check out the parts. The etching might be possible but I don't know much about that process. Photo87.com does do some nice etched stuff. I love their spikes! Best, Rambling Todd... |

Re: C&S Switch Chairs and Ball Throws...

|

I do tend to get a bit wordy in my posts . . . and I do love to post pictures!

I agree with you about appearances. In the 2nd photo I posted, the code 55 No. 6 stub switch somehow looks sharper than the code 70 No. 6 conventional switch just above it. Both were built up in fast tracks No. 6 jigs, both have the same frog angle and identical diverging rail geometry. The C&S Standards track work sheets in the "Files" section show a No. 8 1/2 stub switch to be the standard for the narrow gauge. Since the C&Sng used stubs on the mainline, I may have to get a code 55 No. 8 jig to build future C&S stub switches. And yes, Bill and the gang at Ukiah, do work to their own drummer. I just wish Bill and Tom Marsh, back in the mid-1980s, hadn't decided to divide the Sn3 world (like the Spanish and Portuguese divided the New World) with Overland producing C&S stuff and PBL doing D&RGW/RGS. I would have loved to see PBL versions of the rebuilt 2-6-0s, the Rhode Islands and the Baldwin B-4-Ds!

Jim Courtney

Poulsbo, WA |

Re: C&S Switch Chairs and Ball Throws...

|

Jim,

I have suggested a few things to Bill over the years. Generally things I think he should think about producing. His usual answer is “You go ahead and do that and let me know how it turns out!” I even suggested that they do a Georgetown Loop bridge in lifetime brass as a 25th Anniversary model. Now I figured the market was probably 25 and the cost would probably be $2000 15 years ago. But it would have been a spectacular bridge done to full scale! I think even the RGS and D&RGW guys may have wanted one! To tell the truth I was somewhat surprised to see them do the 74, 75 and 76 models. But they probably had to do the 4 versions to get enough models to make the production run. Production run is usually 100 to 150 models for their brass models. I remember when I visited Bill and I were talking about the number of models in a run. He showed me a closet full or the RGS long caboose 0404 that they still had at least 10 years after they were produced. I forget what the number was that he said they made but it i recall him saying they would never sell them all, never… I have always thought his sort of partnership arrangement for getting brass models done was pure genius that most importers could not get away with doing. Basically a third down for each model at reservation time, another third when they models were ready to be produced and the final third when they shipped to the USA. He made that work and it was a good system. I do recall some models taking ears to appear, but they were usually worth the wait. I think I waited about 4-5 years for the UTLX tank cars in brass. A once in a lifetime deal as Bill told me that they sent 3 plastic kits to get the parts for 1 brass model. I think they only ended up getting about 100 cars complete out of that run. I bought 6, they are nice but they tie up some money for sure too. I sometimes wonder if we will ever see another C&S locomotive produced in O or S scale in brass. It might not happen again. I can’t believe that they made On30 cars and locos and didn’t really follow any prototypes. Why not just do the stuff in On3 and follow prototypes. It could have been a huge growth for On3 just like Blackstone and MicroTrains brought back HOn3. I heard it was because it could use HO track, but they ultimately retooled new On30 track and turnouts that looked better than On30 on HO track. Oh Well… Best, Todd

|

Re: C&S Switch Chairs and Ball Throws...

|

Silly question/ observation.

First the observation. At a stub turnout with a harp stand, the target position indicates which route the switch is not aligned for. I. e., if the rails ate aligned for the main route, the target is away from the rails, and when the rails are aligned for the diverging route, the target is nearer the rails. However if a harp stand is used with point switch, the opposite is true because the switch stand operates the point rails: the target position indicates which route the switch is aligned for. So...were harps used in point switches?

Keith Hayes

Leadville in Sn3 |

Re: C&S Switch Chairs and Ball Throws...

|

There was at least one point switch at Como-were there others along the South Park? What about Clear Creek?

|

Re: C&S Switch Chairs and Ball Throws...

|

At Fork's. Bob....and somewhere else I've noted and forgotten: you could go and research this as your next contribution.

UpSideDownC

in New Zealand |

Re: C&S Switch Chairs and Ball Throws...

|

In reply to this post by Keith Hayes

Keith,

your answer lies in here......  to your "observation" however I can't ever remember seeing a Harp-controlled Bladed switch. to your "observation" however I can't ever remember seeing a Harp-controlled Bladed switch.

http://c-sng-discussion-forum.41377.n7.nabble.com/What-s-this-harp-stand-being-used-for-td2224.html#a2241 http://c-sng-discussion-forum.41377.n7.nabble.com/How-do-you-model-Elliot-switch-stands-td2229.html#a2239 http://c-sng-discussion-forum.41377.n7.nabble.com/Modelling-stub-switches-td2408.html http://c-sng-discussion-forum.41377.n7.nabble.com/Como-Wye-td2773.html#a2781 http://c-sng-discussion-forum.41377.n7.nabble.com/Switch-stand-support-tie-arrangements-td3411.html http://c-sng-discussion-forum.41377.n7.nabble.com/Harp-stand-target-colours-td3519.html http://c-sng-discussion-forum.41377.n7.nabble.com/Dome-Rock-Switchstand-td5866.html http://c-sng-discussion-forum.41377.n7.nabble.com/Diamonds-in-the-Rough-td5899.html#a5909 The amount of information contained in the archives should not be forgotten.

UpSideDownC

in New Zealand |

|

In reply to this post by Todd A Ferguson

It's probably worth reviewing the Fast Tracks guide for building stub switches using their jigs, even if you're not using their products: http://help.fast-tracks.net/customer/en/portal/articles/2431407-building-a-stub-switch-using-a-fast-tracks-assembly-fixture-

dave |

Re: C&S Switch Chairs and Ball Throws...

|

Have done that in the past Dave. Thanks for sharing with the group…

Todd

|

Re: C&S Switch Chairs and Ball Throws...

Re: C&S Switch Chairs and Ball Throws...

These photos you suggest the existence there of, I await the posting of such with much anticipation.....

UpSideDownC

in New Zealand |

Re: C&S Switch Chairs and Ball Throws...

A conundrum here indeed. I’d agree with Todd’s post, except that said “someone” is usually Chris, and if he’s “awaiting with much anticipation” then he must have come up empty himself…. |

«

Return to C&Sng Discussion Forum

|

1 view|%1 views

| Free forum by Nabble | Edit this page |

to your "observation" however I can't ever remember seeing a Harp-controlled Bladed switch.

to your "observation" however I can't ever remember seeing a Harp-controlled Bladed switch.