Re: Along The Gilpin Tramway - A Closer Look

Posted by Keith Pashina on Jan 08, 2025; 12:04am

URL: http://c-sng-discussion-forum.254.s1.nabble.com/Along-The-Gilpin-Tramway-A-Closer-Look-tp20380p20422.html

First, I want to provide a correction. I had previously said on the December 19th post that I didn’t think that the Castle Rock Mine was a Gilpin Tram shipper – well, it turns out that they did at least twice. The Gilpin Railroad Company “Report of Business for the Month April 1914” shows that the Castle Rock Mine shipped 10 cars of ore that month – 5 each to the Iron City Mill and to the Polar Star Mill. The mine was high up on the hillside above the the track, and there is no record of a spur here. Perhaps ore cars were temporarily parked on the main line or Tucker Mill branch, and ore loads teamed by horse and wagon down to the waiting ore cars. There is also a record of some cars shipped in April 1913, too.

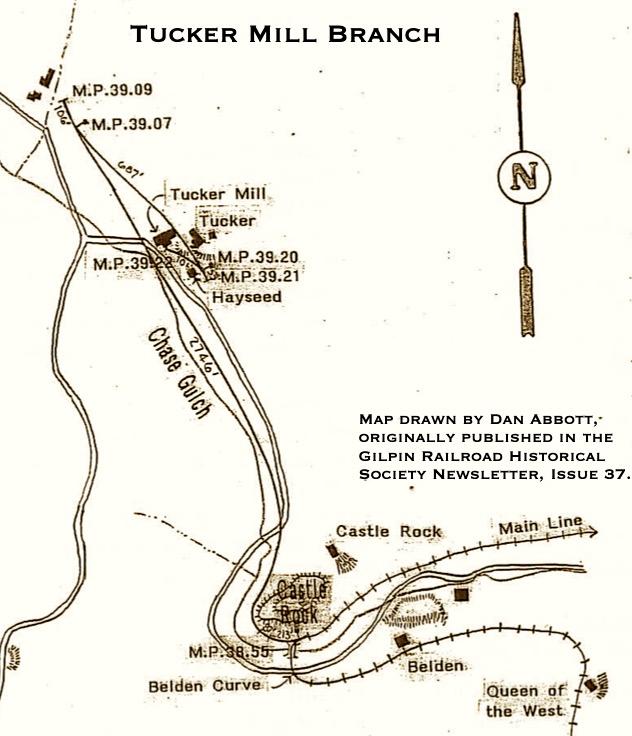

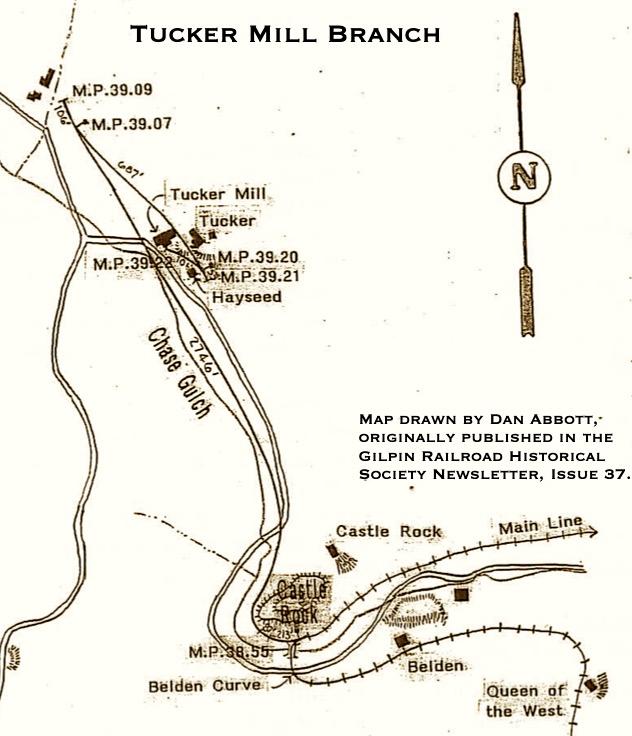

Before heading up the Gilpin Tram main line, we’ll take a short side trip up the Tucker Mill branch. This short branch, a bit over 3,700 feet long, was built in stages.

Tucker Mill Branch

The branch originally began as a short 213 foot long spur off of the main line, built in May 1907. This was extended in September 1907. Dan Abbott wrote in the Gilpin Railroad Historical Society Newsletter, Issue #2, that: “Soon after this initial construction, the Tucker Mill – which was owned by F.W. Hearne and company – requested an additional 3,000 foot extension to their mill, and while negotiations were under way the Tucker Mill people constructed 87’ of this spur themselves in order to take care of their ore business which they were then shipping by wagon.” The total length of the branch was eventually 3,790 feet.

The 3,000 foot branch extension was built by the Gilpin Tramway, on grading, ties and right-of-way provided by the F.W. Hearne and Company. Apparently this track didn’t quite go far enough, as the Hearne Company requested it be extended another 245’.

Map showing the Tucker Mill Branch trackage.

So, this first branch construction had one turnout included. Dan Abbott goes on to write in the Gilpin Railroad Historical Society Newsletter, Issue #2, “The cost to the Gilpin Railroad Company for this 3,000 foot extension of Tucker Mill spur was $1,440 – which included 6,000 lineal feet of forty-pound steel rail; 200 pair angle bars; 600-pounds track bolts; 3400 -pounds spikes; one switch stand and connecting rod; two head chairs (single throw); one head rod; two bridle rods; one #8 ½ rigid frog; and the labor for laying and surfacing.”

Lots of interesting details here – for example the spur was laid with the “heavy” 40-pound rail instead of 30-pound rail. And the turnout was a 8 ½ point frog.

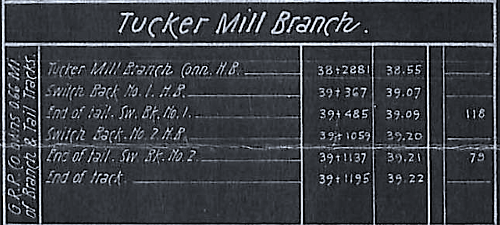

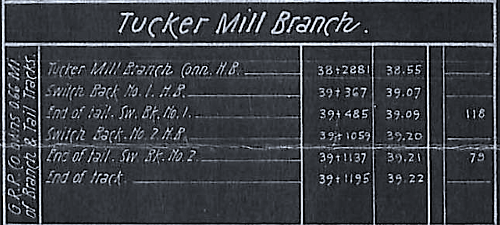

Tucker Mill branch trackage from C&S track chart.

The F. W. Hearne thought that they owned 332’ of the branch. However, the C&S initially disputed this, and several items of correspondence ensued. Dan Abbott discovered some interesting tidbits. The C&S’ General Auditor, J. H. Bradbury, dated April 6, 1909, stated, “it appears from the record that the Tucker Mill Company constructed 332 feet of the spur to their mill…” The auditor was questioning whether this was on C&S property (it was not) and where the Hearne company got the track material? The manager of the Hearne Company coyly declined to enlighten the C&S about where they had gotten their track material.

Dan Abbott goes on to write about C&S Superintendent Sol Morris, who replied in a later letter to the Auditor on April 28th, that, “As close as I can find from parties now there the material for this track was taken off the Pease-Kansas Branch by our former foreman Charles Mathas, and I am inclined to think, although I cannot confirm it, that H.W. Kane (Hearne Company’s manager) paid Mathas for this track, at least they paid him for doing this work and Mathas furnished the material…’ Superintendent Morris went on to say,”…It is a very easy matter for a foreman, who is inclined to be on the graft, to do work for this mine people and it would not be detected for some time to come.”

So, the C&S decided to avoid controversy, and recognize that the Hearne and Company owned the 332’ of track. And, it sounds like the former Gilpin Tram foreman got away with “borrowing” some track material. The Gilpin Tram didn’t hesitate to take up track from unused mine spurs, and there are several records doing this themselves.

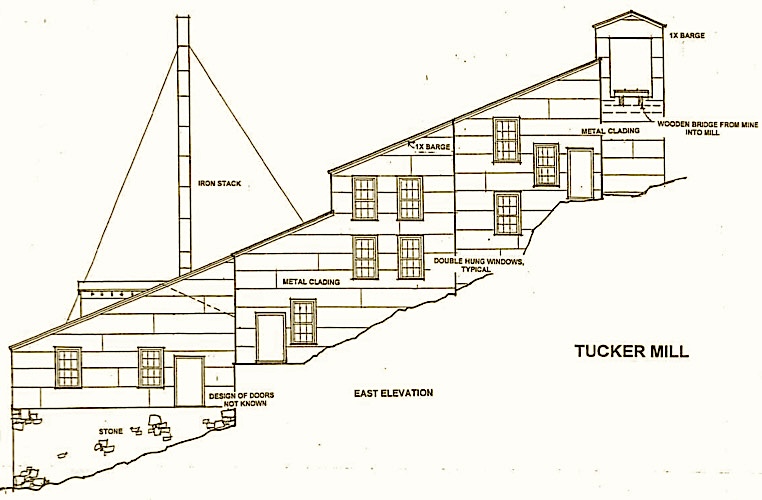

Photo of the Tucker Mill and Mine at the end of the branch - from the Denver Public Library.

The Tucker Mill was apparently built and started up in 1903, as reported by the Gilpin Observer on February 12m 1903. The ore came from the adjacent Tucker Mine at the time. The mill had two water storage tanks for ore operations, and the water came from a spring inside the nearby Gundy Mine, which the Tucker Mill had purchased to secure this source.

The Tucker Mill was very busy by 1909. This mill was reported to have one jaw crusher, three sets of rolls, three trammels, five Hartz jigs, ten stamps and three Wilfley tables. This mill could process 50 tons in a day. On March 6 1909, the Mining & Scientific Press reported that the Hearne Gold & Copper Mining Company operated the mill, and it had been upgraded to 10 stamps and could now process 75 tons per day. They were handling ore from the Anchor Mine at the time.

By August 17, 1911, the situation had changed some, and the Tucker Mill was leased to J.A. Lind and C.A. Jackson of Black Hawk, and processing ore from the Hazeltine mine (which was also on the Anchor Mine branch).

This shot shows the Tucker Mill and Mine. This is from the Denver Public Library Western History Collection, and is an enlargement of the background of a photo showing Castle Rock.

A second switchback was added at some time – this was very short, just long enough for a locomotive and one car. Dan Abbott wrote about how the Tucker Mill branch could have been operated. His musings were in the Gilpin Railroad Historical Society Newsletter, Issue 37:

“Assuming that each of the Shays were backed into the engine house each night, we now take Shay No.4 from the engine house up the Fullerton Mill Branch (686 feet) to the Clear Creek Wye where our Shay is turned and then proceeds down to the Warming House siding to pick up our four ore cars. At this point we have a train consisting of an engine - average length of 28 feet - and four ore cars - average length at 17 feet each - which gives our train a total length of 96 feet.

After hooking on to the four ore cars the train then backs up the track to the mainline switch near the engine house and proceeds to the Tucker Mill Branch switch which was located near Belden Curve. Remember our engine is pushing the cars ahead of it at this point.

Proceeding up this branch to the first switchback - whose tail track was 106 feet long - our train crew will spot three ore cars here, uncoupling the ore car nearest the engine and then back up the branch to the second switchback - whose tail track was only 56 feet long, only enough room for one car and the engine. From this point our engine will push its ore car down grade to the Tucker Mill and uncouple.

While this ore car was being unloaded at the Tucker Mill our Shay would then proceed with switching tasks on other portions of the Gilpin line. Once unloaded the engine would then hook onto the ore car again and stage ti on the mainline near Belden Curve, then proceed back to the first switchback - where three loaded ore cars remained, hook onto another one and repeat the same switching maneuver until all the cars were unloaded at the mill, which probably took the better part of the day.”

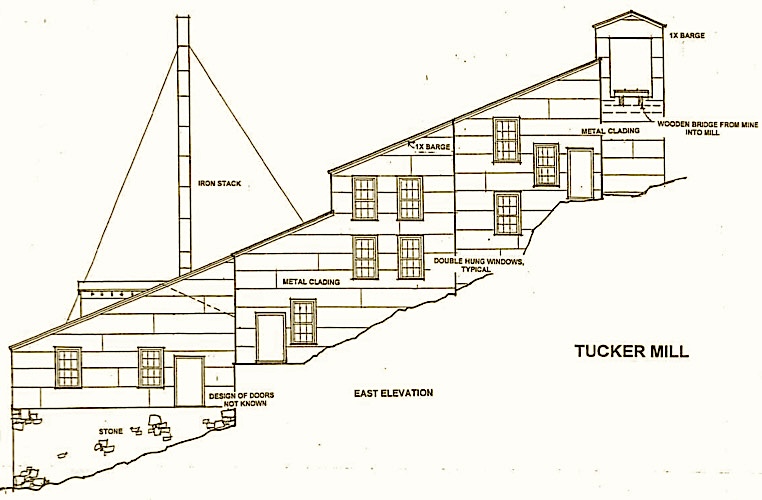

Mike Blazek drew plans for the Tucker Mill – here is the east elevation.

URL: http://c-sng-discussion-forum.254.s1.nabble.com/Along-The-Gilpin-Tramway-A-Closer-Look-tp20380p20422.html

First, I want to provide a correction. I had previously said on the December 19th post that I didn’t think that the Castle Rock Mine was a Gilpin Tram shipper – well, it turns out that they did at least twice. The Gilpin Railroad Company “Report of Business for the Month April 1914” shows that the Castle Rock Mine shipped 10 cars of ore that month – 5 each to the Iron City Mill and to the Polar Star Mill. The mine was high up on the hillside above the the track, and there is no record of a spur here. Perhaps ore cars were temporarily parked on the main line or Tucker Mill branch, and ore loads teamed by horse and wagon down to the waiting ore cars. There is also a record of some cars shipped in April 1913, too.

Before heading up the Gilpin Tram main line, we’ll take a short side trip up the Tucker Mill branch. This short branch, a bit over 3,700 feet long, was built in stages.

Tucker Mill Branch

The branch originally began as a short 213 foot long spur off of the main line, built in May 1907. This was extended in September 1907. Dan Abbott wrote in the Gilpin Railroad Historical Society Newsletter, Issue #2, that: “Soon after this initial construction, the Tucker Mill – which was owned by F.W. Hearne and company – requested an additional 3,000 foot extension to their mill, and while negotiations were under way the Tucker Mill people constructed 87’ of this spur themselves in order to take care of their ore business which they were then shipping by wagon.” The total length of the branch was eventually 3,790 feet.

The 3,000 foot branch extension was built by the Gilpin Tramway, on grading, ties and right-of-way provided by the F.W. Hearne and Company. Apparently this track didn’t quite go far enough, as the Hearne Company requested it be extended another 245’.

Map showing the Tucker Mill Branch trackage.

So, this first branch construction had one turnout included. Dan Abbott goes on to write in the Gilpin Railroad Historical Society Newsletter, Issue #2, “The cost to the Gilpin Railroad Company for this 3,000 foot extension of Tucker Mill spur was $1,440 – which included 6,000 lineal feet of forty-pound steel rail; 200 pair angle bars; 600-pounds track bolts; 3400 -pounds spikes; one switch stand and connecting rod; two head chairs (single throw); one head rod; two bridle rods; one #8 ½ rigid frog; and the labor for laying and surfacing.”

Lots of interesting details here – for example the spur was laid with the “heavy” 40-pound rail instead of 30-pound rail. And the turnout was a 8 ½ point frog.

Tucker Mill branch trackage from C&S track chart.

The F. W. Hearne thought that they owned 332’ of the branch. However, the C&S initially disputed this, and several items of correspondence ensued. Dan Abbott discovered some interesting tidbits. The C&S’ General Auditor, J. H. Bradbury, dated April 6, 1909, stated, “it appears from the record that the Tucker Mill Company constructed 332 feet of the spur to their mill…” The auditor was questioning whether this was on C&S property (it was not) and where the Hearne company got the track material? The manager of the Hearne Company coyly declined to enlighten the C&S about where they had gotten their track material.

Dan Abbott goes on to write about C&S Superintendent Sol Morris, who replied in a later letter to the Auditor on April 28th, that, “As close as I can find from parties now there the material for this track was taken off the Pease-Kansas Branch by our former foreman Charles Mathas, and I am inclined to think, although I cannot confirm it, that H.W. Kane (Hearne Company’s manager) paid Mathas for this track, at least they paid him for doing this work and Mathas furnished the material…’ Superintendent Morris went on to say,”…It is a very easy matter for a foreman, who is inclined to be on the graft, to do work for this mine people and it would not be detected for some time to come.”

So, the C&S decided to avoid controversy, and recognize that the Hearne and Company owned the 332’ of track. And, it sounds like the former Gilpin Tram foreman got away with “borrowing” some track material. The Gilpin Tram didn’t hesitate to take up track from unused mine spurs, and there are several records doing this themselves.

Photo of the Tucker Mill and Mine at the end of the branch - from the Denver Public Library.

The Tucker Mill was apparently built and started up in 1903, as reported by the Gilpin Observer on February 12m 1903. The ore came from the adjacent Tucker Mine at the time. The mill had two water storage tanks for ore operations, and the water came from a spring inside the nearby Gundy Mine, which the Tucker Mill had purchased to secure this source.

The Tucker Mill was very busy by 1909. This mill was reported to have one jaw crusher, three sets of rolls, three trammels, five Hartz jigs, ten stamps and three Wilfley tables. This mill could process 50 tons in a day. On March 6 1909, the Mining & Scientific Press reported that the Hearne Gold & Copper Mining Company operated the mill, and it had been upgraded to 10 stamps and could now process 75 tons per day. They were handling ore from the Anchor Mine at the time.

By August 17, 1911, the situation had changed some, and the Tucker Mill was leased to J.A. Lind and C.A. Jackson of Black Hawk, and processing ore from the Hazeltine mine (which was also on the Anchor Mine branch).

This shot shows the Tucker Mill and Mine. This is from the Denver Public Library Western History Collection, and is an enlargement of the background of a photo showing Castle Rock.

A second switchback was added at some time – this was very short, just long enough for a locomotive and one car. Dan Abbott wrote about how the Tucker Mill branch could have been operated. His musings were in the Gilpin Railroad Historical Society Newsletter, Issue 37:

“Assuming that each of the Shays were backed into the engine house each night, we now take Shay No.4 from the engine house up the Fullerton Mill Branch (686 feet) to the Clear Creek Wye where our Shay is turned and then proceeds down to the Warming House siding to pick up our four ore cars. At this point we have a train consisting of an engine - average length of 28 feet - and four ore cars - average length at 17 feet each - which gives our train a total length of 96 feet.

After hooking on to the four ore cars the train then backs up the track to the mainline switch near the engine house and proceeds to the Tucker Mill Branch switch which was located near Belden Curve. Remember our engine is pushing the cars ahead of it at this point.

Proceeding up this branch to the first switchback - whose tail track was 106 feet long - our train crew will spot three ore cars here, uncoupling the ore car nearest the engine and then back up the branch to the second switchback - whose tail track was only 56 feet long, only enough room for one car and the engine. From this point our engine will push its ore car down grade to the Tucker Mill and uncouple.

While this ore car was being unloaded at the Tucker Mill our Shay would then proceed with switching tasks on other portions of the Gilpin line. Once unloaded the engine would then hook onto the ore car again and stage ti on the mainline near Belden Curve, then proceed back to the first switchback - where three loaded ore cars remained, hook onto another one and repeat the same switching maneuver until all the cars were unloaded at the mill, which probably took the better part of the day.”

Mike Blazek drew plans for the Tucker Mill – here is the east elevation.

Keith Pashina

Narrow-minded in Arizona

Narrow-minded in Arizona

| Free forum by Nabble | Edit this page |