Re: Building Leadville Designs Coal Car / Flat Car / Cinder Car Kits in C&Sn3

Posted by Jim Courtney on Aug 12, 2024; 8:13pm

URL: http://c-sng-discussion-forum.254.s1.nabble.com/Building-Leadville-Designs-Coal-Car-Flat-Car-Cinder-Car-Kits-in-C-Sn3-tp19966p20022.html

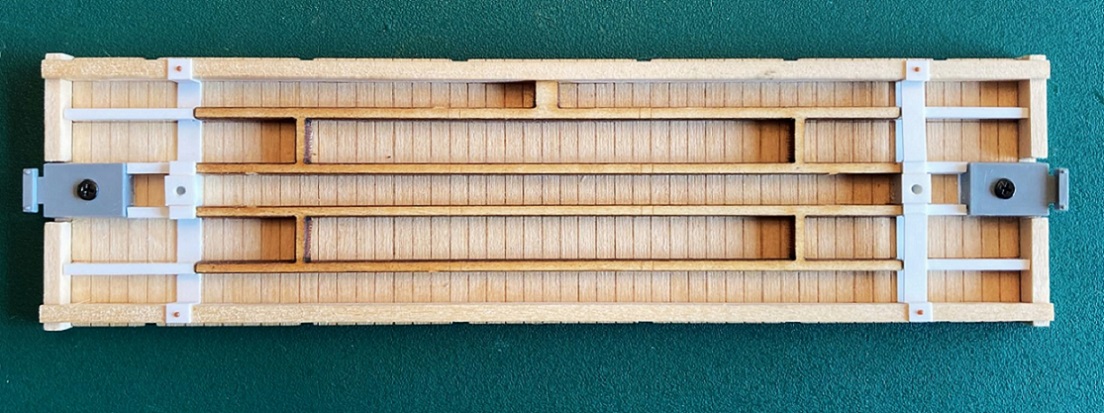

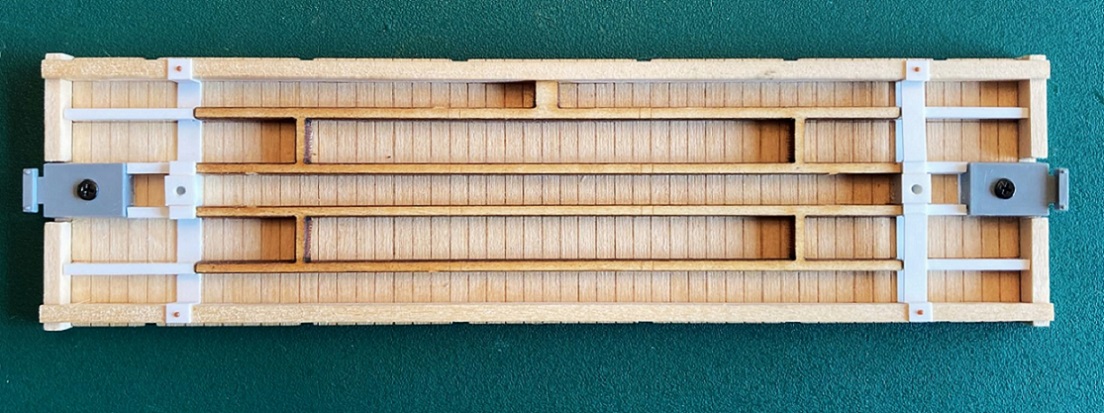

Some progress over the past week. I've been slowly building up the other three kits so that the floor/frame/trucks and couplers reach the same level of completion as the first kit, above. I've been using the same assembly sequence, with one major exception . . .

1898 St. Charles Bolsters:

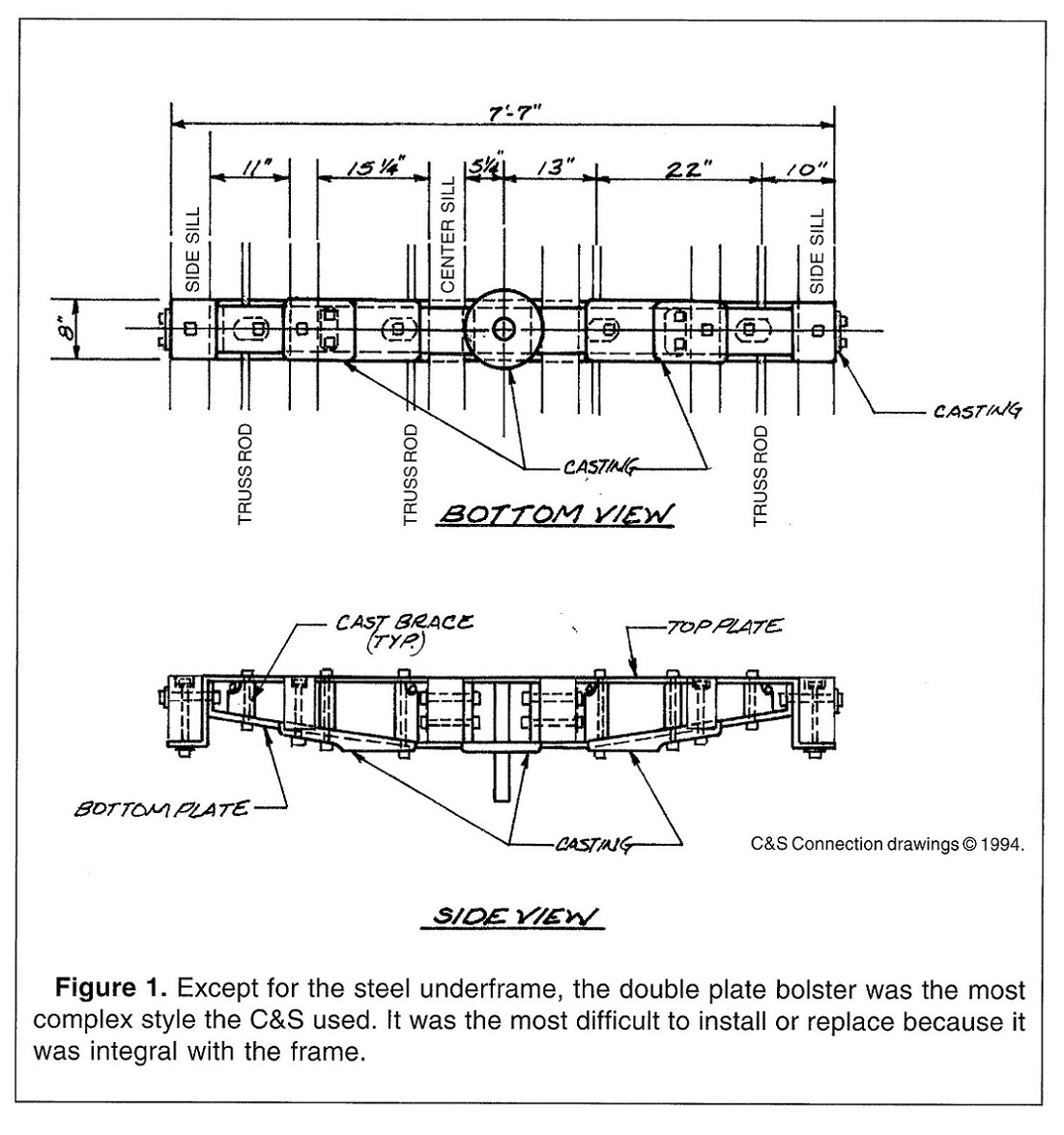

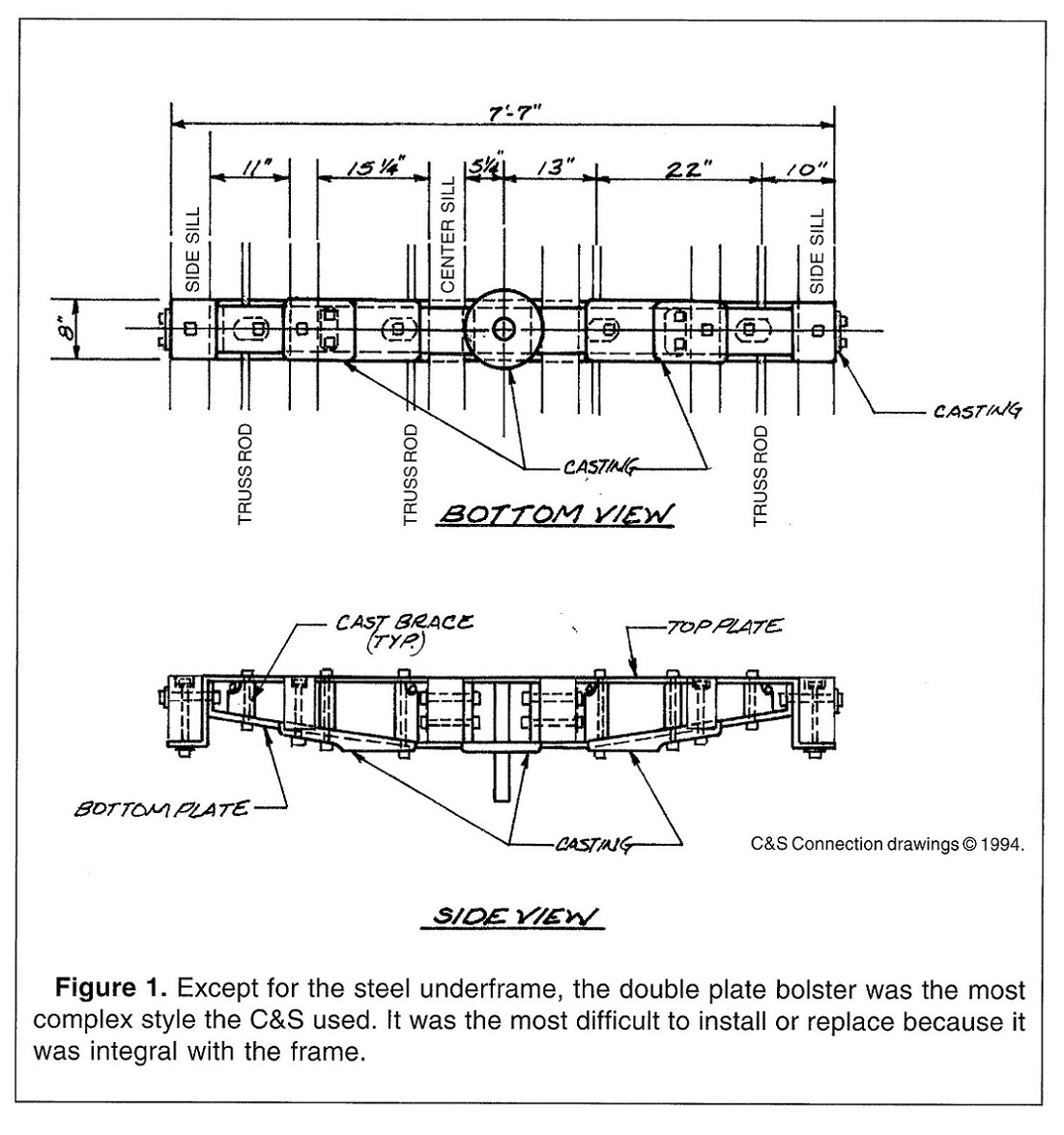

The cast brass bolsters in the kit represent the cast bolsters that the C&S shops purchased from American Steel & Foundry, along with the ASF arch bar trucks, for the 1902 construction of the coal cars and flat cars. The coal cars built by St. Charles in 1898 used the St. Charles double plate bolster:

Derrell Poole drawing, published in Outdoor Railroading, 1995

As I'm building one of the four kits as an 1898 St. Charles coal car for my 1901 freight roster, I decided to build up the bolsters from styrene.

To avoid having to modify my Cimarron Works St. Charles trucks, I used Mr. Micrometer to calculate the height of the needed bolster, from bottom of car floor to lower bolster bearing plate, by my estimation 0.190".

I used S scale styrene 4x8 strip to extend the intermediate sills from the end of the wood sills to flush with the end of the floor. Then the end beams were added as in the last post, and the tops of the beams sanded flush with the top of the floor. The modified PBL draft gear boxes were then attached, again as above. Then more of the 4x8 strip was cut to extend the wood center sills to the draft gear boxes. A piece of S scale 8x8 was cut to fit between the two center sill extensions as a pad for mounting the truck screws.

The 4x8 center sills have an actual height of 0.13". I cut styrene 0.040 x 0.125'' strip to width, over the outside edges of the center sills, as a bolster build up, bringing the central height of the bolster to 0.170". Finally, a bearing plate was cut from 0.015" strip to form a 10" square and centered over the bolster block. The entire assembly was drilled and tapped for 1.4 mm screws and the trucks were mounted. Though the entire bolster build up was only 0.185", the car height seemed right on!

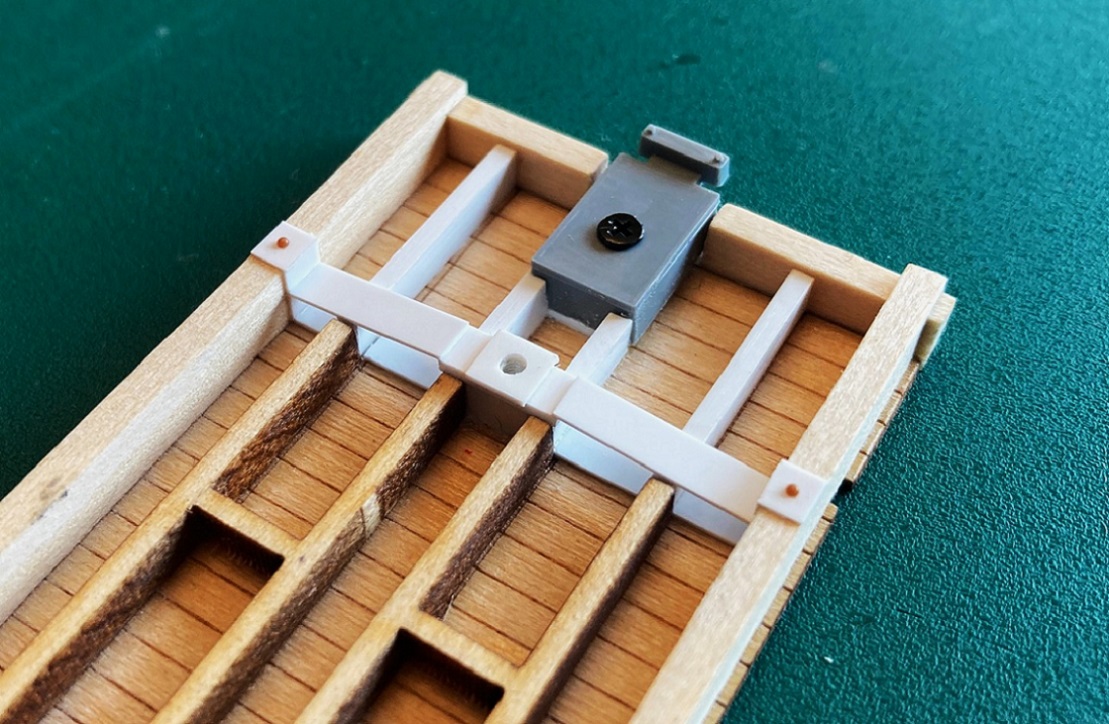

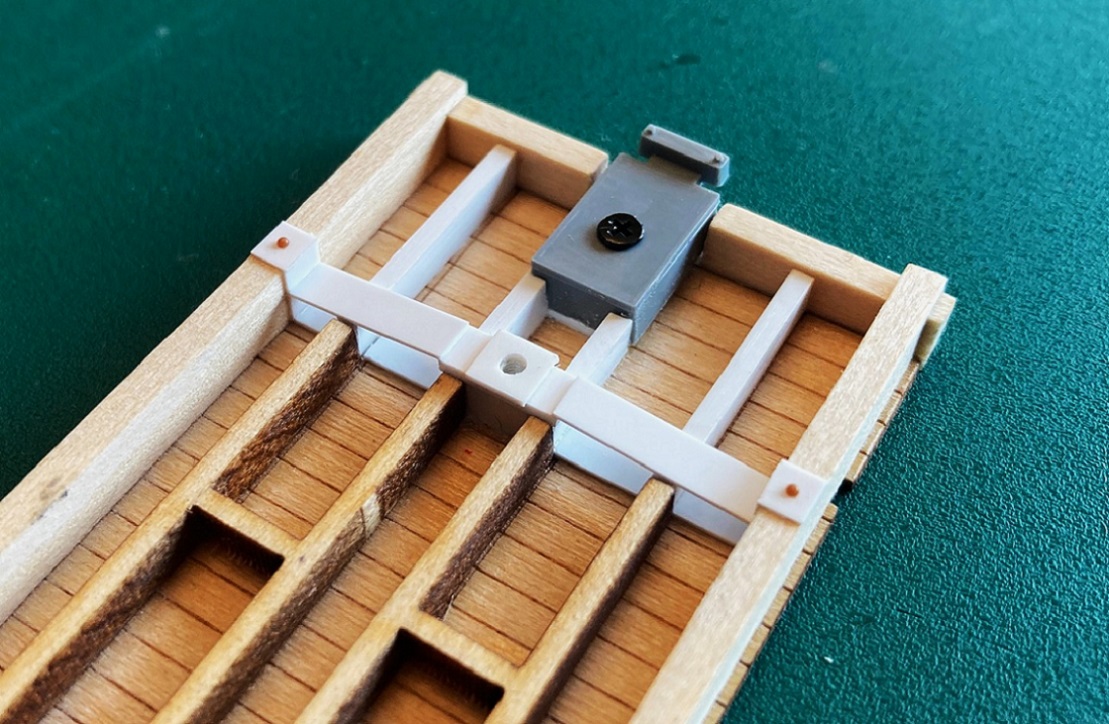

I built up the double plate bolster using 0.015 x 0.125" strip for the bottom plate, against the floor, and 0.010 x 0.125" strip for the L-bracket under the side sills (above, left). Then the bottom plate was cut to length, by trial and error, from 0.015 x 0.125" strip and attached (above, right).

The deep side sills and mounted trucks make the center of the bolster impossible to see, so no time was spent trying to detail that part of the bolster. I did add Tichy 0.030" bolt heads to the bottom of the sill bracket. All that can really be seen on either type of bolster is the bottom of the sill bracket--the 1898 bolster had a single bolt head, while the 1902 ASF bolster had two bolt heads separated by the semicircular fin.

I built up the end striker blocks and face plate with the precut parts described in the last post. I used this photo of the end of a St. Charles coal car, c1900 to detail the striker plate, one of many great photos posted on the Forum by our late friend, Doug Heitkamp:

The 1898 cars did not use nuts on washers to secure the truss rods to the ends, rather the truss rod ends were about 2.5" square bolt heads--evidently, the truss rods could only be tightened with the turnbuckles. I cut the square bolt heads from 0.010 x .0.40" styrene and used Tichy 0.030" rivets above. Don't forget to drill the vertical hole for the "B" end brake staff before attaching the completed striker block/plate assembly to the ends!

Once the end striker blocks were attached I decided, since I was cutting square bolt heads, to attach the vertical rectangular washers and bolt heads to the outboard of the end beams:

To further test the ability to use MEK to attach styrene details to the Dullcote sealed wood, I decide to add Tichy rivets for the brake hanger attachments. So far, so good. Nothing has fallen off yet!

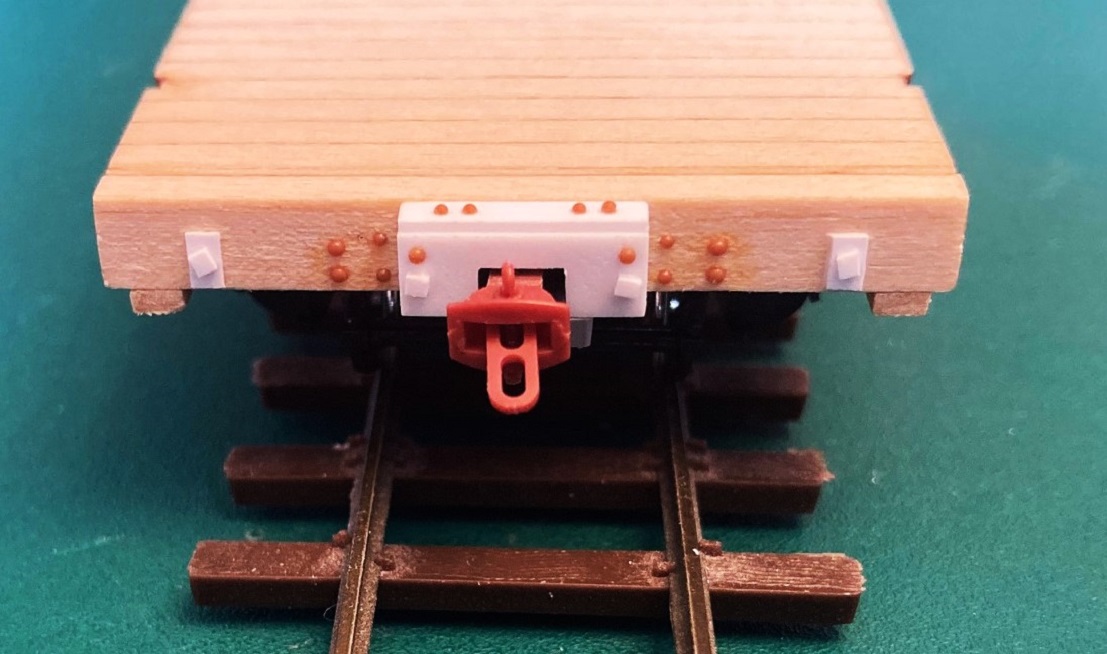

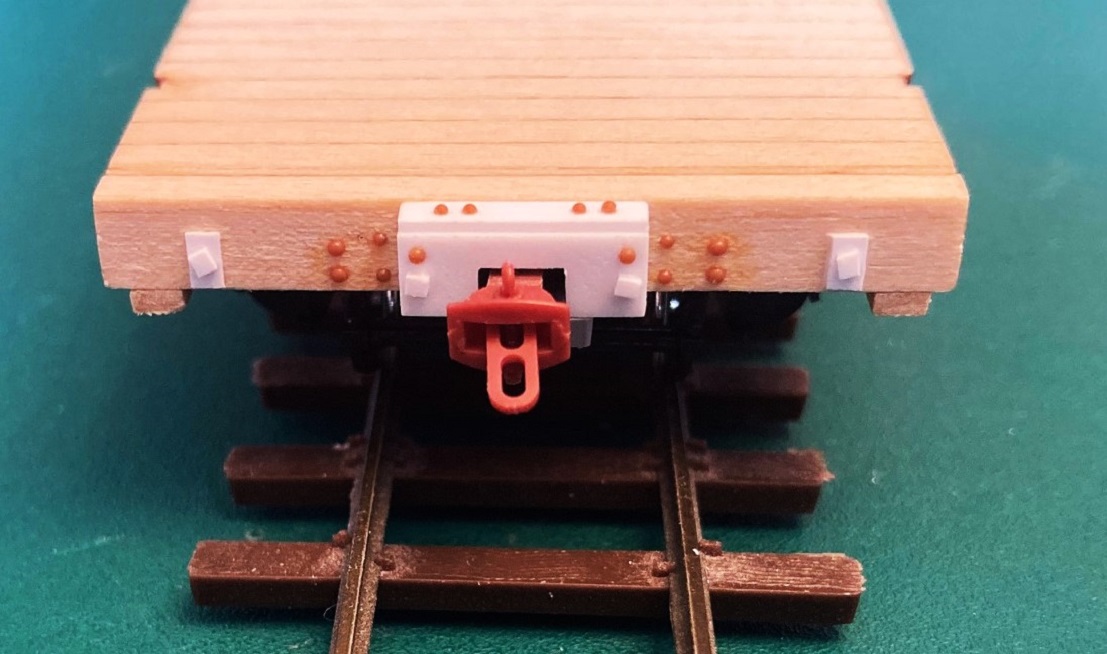

The link-n-pin couplers are O scale parts from Foot Hill Model Works. They are small logging couplers in O scale, just about right for TOTC C&S couplers.

Hopefully, the next post will have all four kits up to speed, ready for weathering the deck boards and proceeding with further construction.

URL: http://c-sng-discussion-forum.254.s1.nabble.com/Building-Leadville-Designs-Coal-Car-Flat-Car-Cinder-Car-Kits-in-C-Sn3-tp19966p20022.html

Some progress over the past week. I've been slowly building up the other three kits so that the floor/frame/trucks and couplers reach the same level of completion as the first kit, above. I've been using the same assembly sequence, with one major exception . . .

1898 St. Charles Bolsters:

The cast brass bolsters in the kit represent the cast bolsters that the C&S shops purchased from American Steel & Foundry, along with the ASF arch bar trucks, for the 1902 construction of the coal cars and flat cars. The coal cars built by St. Charles in 1898 used the St. Charles double plate bolster:

Derrell Poole drawing, published in Outdoor Railroading, 1995

As I'm building one of the four kits as an 1898 St. Charles coal car for my 1901 freight roster, I decided to build up the bolsters from styrene.

To avoid having to modify my Cimarron Works St. Charles trucks, I used Mr. Micrometer to calculate the height of the needed bolster, from bottom of car floor to lower bolster bearing plate, by my estimation 0.190".

I used S scale styrene 4x8 strip to extend the intermediate sills from the end of the wood sills to flush with the end of the floor. Then the end beams were added as in the last post, and the tops of the beams sanded flush with the top of the floor. The modified PBL draft gear boxes were then attached, again as above. Then more of the 4x8 strip was cut to extend the wood center sills to the draft gear boxes. A piece of S scale 8x8 was cut to fit between the two center sill extensions as a pad for mounting the truck screws.

The 4x8 center sills have an actual height of 0.13". I cut styrene 0.040 x 0.125'' strip to width, over the outside edges of the center sills, as a bolster build up, bringing the central height of the bolster to 0.170". Finally, a bearing plate was cut from 0.015" strip to form a 10" square and centered over the bolster block. The entire assembly was drilled and tapped for 1.4 mm screws and the trucks were mounted. Though the entire bolster build up was only 0.185", the car height seemed right on!

I built up the double plate bolster using 0.015 x 0.125" strip for the bottom plate, against the floor, and 0.010 x 0.125" strip for the L-bracket under the side sills (above, left). Then the bottom plate was cut to length, by trial and error, from 0.015 x 0.125" strip and attached (above, right).

The deep side sills and mounted trucks make the center of the bolster impossible to see, so no time was spent trying to detail that part of the bolster. I did add Tichy 0.030" bolt heads to the bottom of the sill bracket. All that can really be seen on either type of bolster is the bottom of the sill bracket--the 1898 bolster had a single bolt head, while the 1902 ASF bolster had two bolt heads separated by the semicircular fin.

I built up the end striker blocks and face plate with the precut parts described in the last post. I used this photo of the end of a St. Charles coal car, c1900 to detail the striker plate, one of many great photos posted on the Forum by our late friend, Doug Heitkamp:

The 1898 cars did not use nuts on washers to secure the truss rods to the ends, rather the truss rod ends were about 2.5" square bolt heads--evidently, the truss rods could only be tightened with the turnbuckles. I cut the square bolt heads from 0.010 x .0.40" styrene and used Tichy 0.030" rivets above. Don't forget to drill the vertical hole for the "B" end brake staff before attaching the completed striker block/plate assembly to the ends!

Once the end striker blocks were attached I decided, since I was cutting square bolt heads, to attach the vertical rectangular washers and bolt heads to the outboard of the end beams:

To further test the ability to use MEK to attach styrene details to the Dullcote sealed wood, I decide to add Tichy rivets for the brake hanger attachments. So far, so good. Nothing has fallen off yet!

The link-n-pin couplers are O scale parts from Foot Hill Model Works. They are small logging couplers in O scale, just about right for TOTC C&S couplers.

Hopefully, the next post will have all four kits up to speed, ready for weathering the deck boards and proceeding with further construction.

Jim Courtney

Poulsbo, WA

Poulsbo, WA

| Free forum by Nabble | Edit this page |