Re: Fifty Gold Mines Mill Car Loader, and Bumping Tables

Posted by drgwcs on

URL: http://c-sng-discussion-forum.254.s1.nabble.com/Roof-Hatches-Mill-Car-Loader-and-Bumping-Tables-tp19659p19661.html

It is at https://digital.denverlibrary.org/nodes/view/1118472?keywords=stamp+mill&type=all&highlights=WyJzdGFtcCIsIm1pbGwiXQ%3D%3D&lsk=2b61579f139a2ab1f0d4a4e2e37ad7c3

Jim

URL: http://c-sng-discussion-forum.254.s1.nabble.com/Roof-Hatches-Mill-Car-Loader-and-Bumping-Tables-tp19659p19661.html

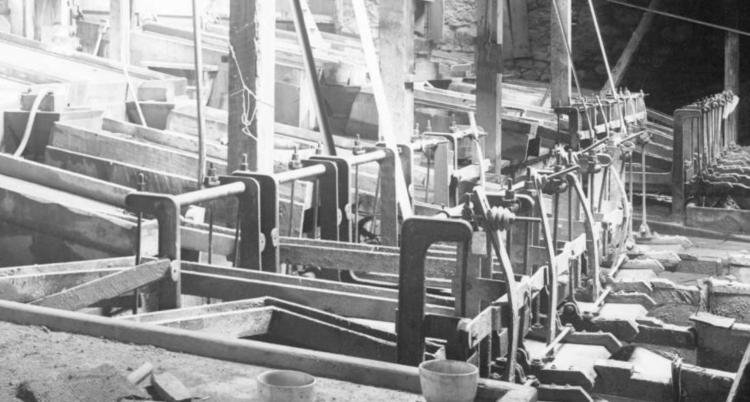

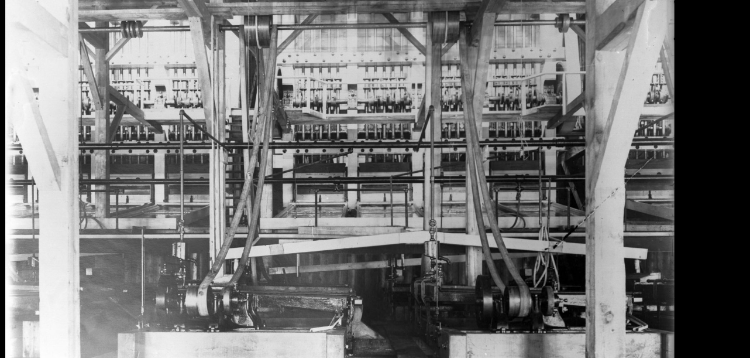

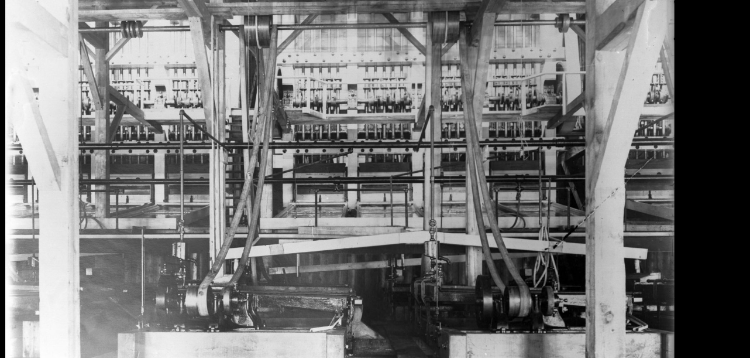

I had seen that bottom photo and wondered if those might be the Gilpin model. For the equipment in the Bobtail there is no real match I have found and there is no name above the stamps (at least that you can tell from the pictures) I have seen a picture in the DPL that is supposedly the Iron City mill that may be an earlier photo of the Bobtail as the stamps look to be the same model BUT the tables are different from what I see (or at least have been heavily modified) The head mechanism appears the same but the table itself is different. I also see some differences in the walkway framing in front of the stamps. When the prospectus was printed they were in the process of moving the tables from cribbing down to the concrete floor so the fat that these are on cribbing is irreverent. What makes me suspect it is the Bobtail is that the stamps barely visible to the extreme right are further forward. This is where the tower/ central ore bin would have been. However the Iron City was also added on to. I go back and forth as to whether this is the Bobtail or not. I found it after I had already framed the back wall so my details would be incorrect. (That is OK- my stamps are a bit wide my mill is too shallow and there are several things that are not right or freelanced as there was not enough info and probably never will be)

It is at https://digital.denverlibrary.org/nodes/view/1118472?keywords=stamp+mill&type=all&highlights=WyJzdGFtcCIsIm1pbGwiXQ%3D%3D&lsk=2b61579f139a2ab1f0d4a4e2e37ad7c3

Jim

Jim Curran

| Free forum by Nabble | Edit this page |