Leadville Designs Baggage/Express 1 in C&Sn3

Posted by Jim Courtney on Oct 02, 2023; 6:27am

URL: http://c-sng-discussion-forum.254.s1.nabble.com/Leadville-Designs-Baggage-Express-1-in-C-Sn3-tp19129.html

I couldn't make it to the NNG convention, so I couldn't pick up my baggage car kits and trucks as did Keith and others. But the USPS left a package from Canada on my front porch yesterday. The cast brass trucks are neat, as Keith has reviewed, but my attention went straight to the baggage car kit. I was surprised and impressed that this Co-Op project turned out so well. Bill has produced a clever kit with an eclectic mixture of materials: Lase cut parts for the body, beautifully rendered resin prints for the major parts, brass and nickel-silver etchings for all the details, and the 5'-6" trucks to make it perfect. Of course, I started building the kit last evening.

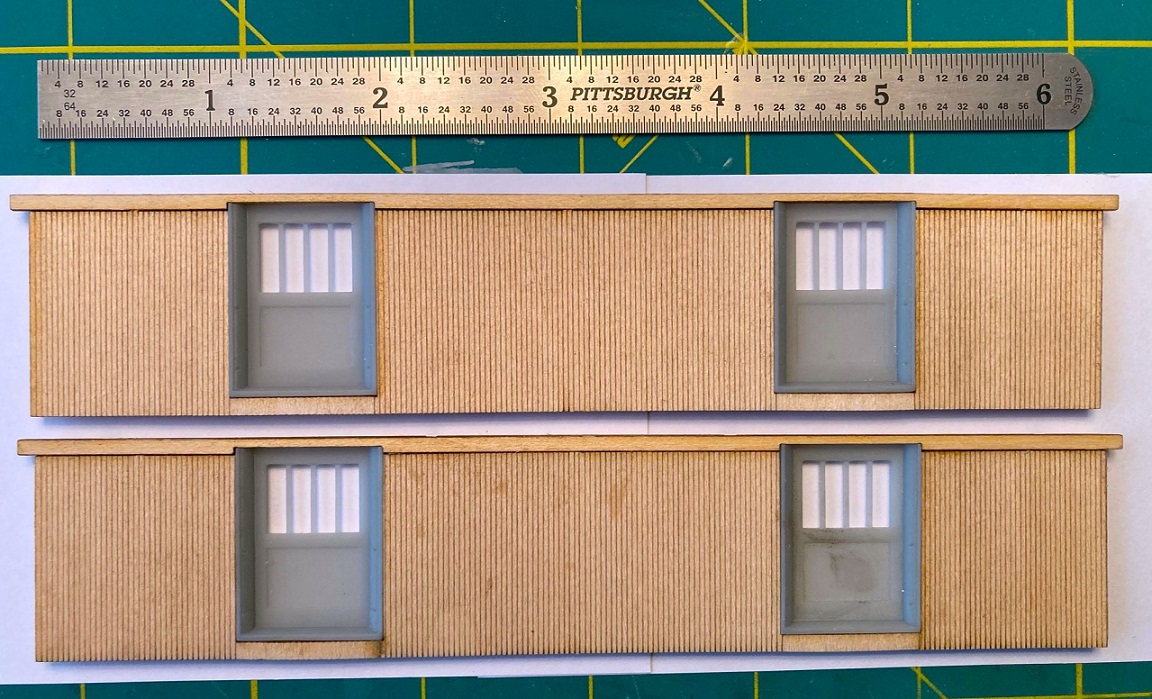

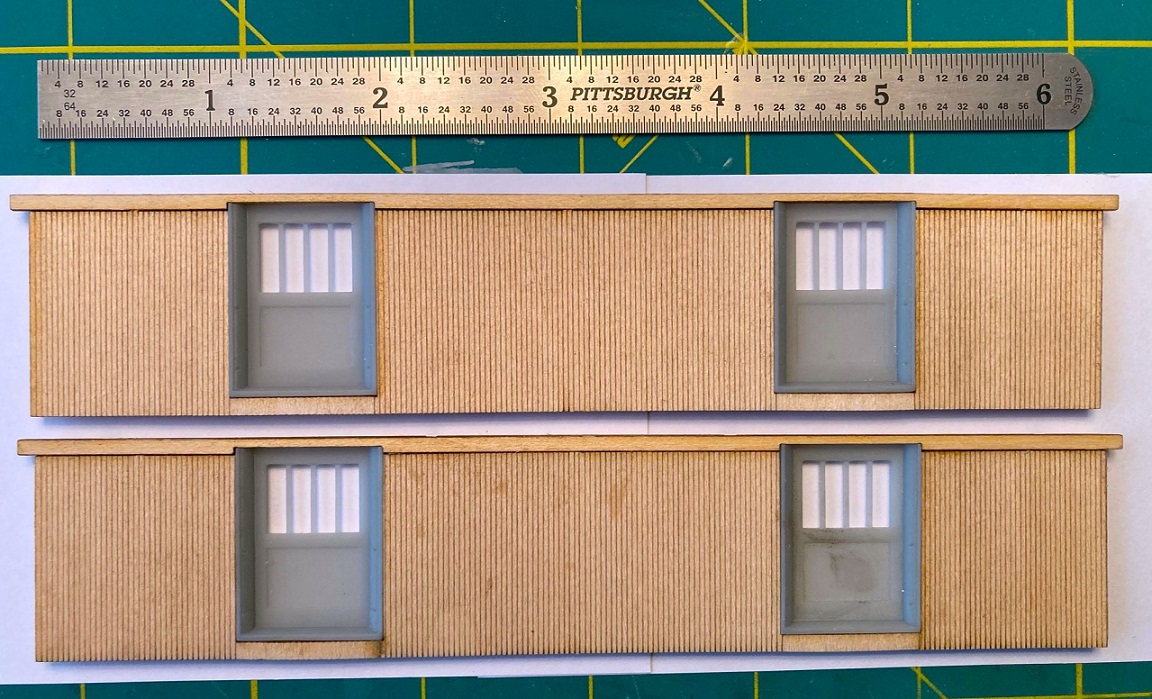

The instructions say to begin by building up the roof. But as I suffer from clerestoryroofaphobia, I decided to build up the sides first to build up my confidence. The sides consist of an inner wall with door cut-outs, and outer very thin (1/32") layer, laser engraved with the sheathing, and a laser cut fascia board. The fascia is glued to the top of the inner wall first. I used Titebond III carpenters glue as it has a bit longer working time to line up things perfectly. I used my Fast Tracks assembly fixture as a thick straight-edge, to keep the top of the fascia board and the top of the inner wall flush.

The sheathing overlay is very fragile, I broke one of the horizontal planks (below the door), was able to repair it. When the overlays had been glued down, I let the wood components dry, under weights, overnight.

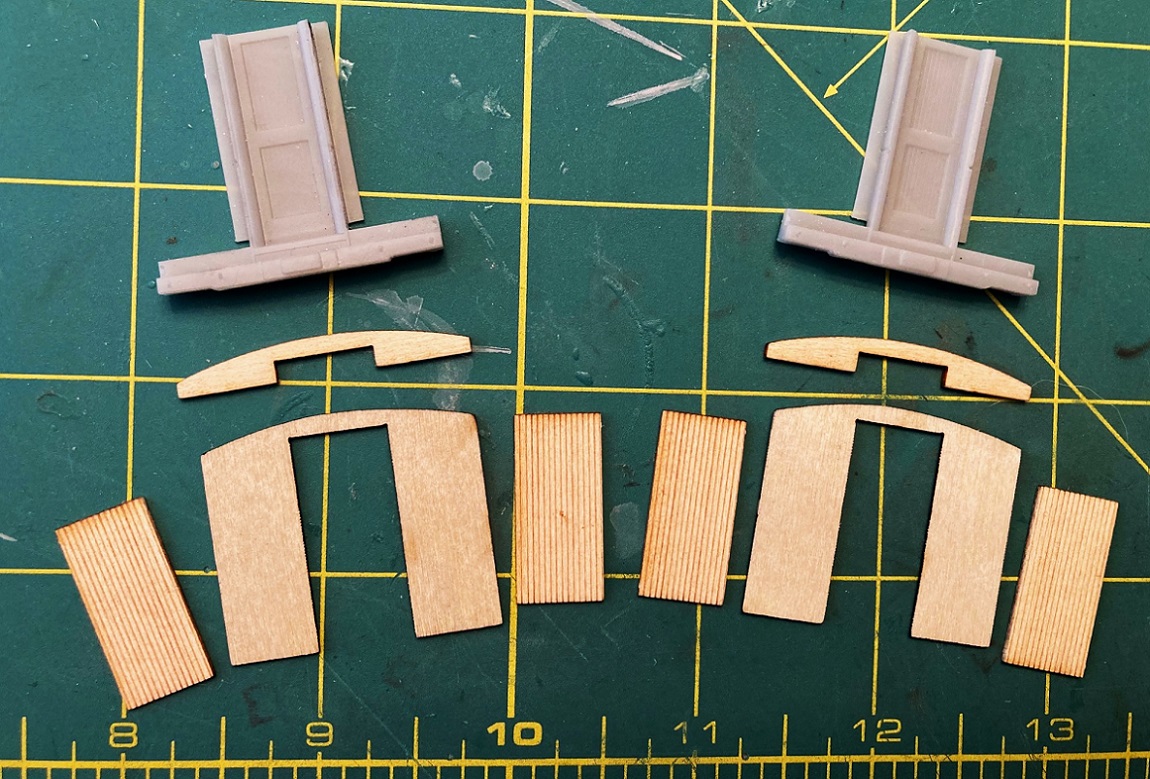

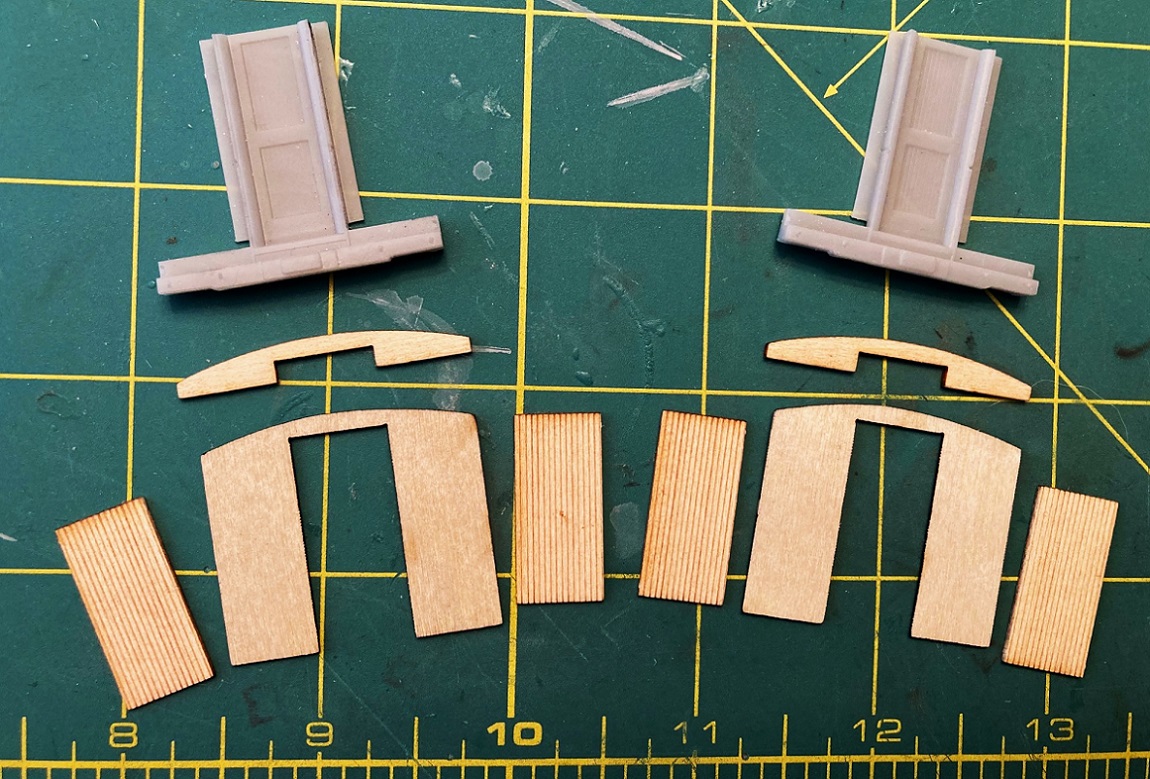

Today, I added the doors. I had dreaded building up 8 pieces of quarter round and trim to frame the doors, but Bill again surprised me with four beautifully detailed side doors as resin prints. When the door openings' sides and tops have been sanded flush, and the corners all squared up, the doors fit into the openings perfectly.

I did have two issues with the doors. Each door has two little side tabs, to allow the doors to be glued to the inner walls. These little tabs are a bit over 0.040" thick. When the doors are inserted into the sides, the vertical trim of the side quarter-round framing are pretty much flush with the side sheathing. IMHO, they and the door threshold should protrude from the sides a bit. So I used a 6" pillar file to carefully fill down the out side surface of each tab (the gluing surface) so that the tabs were only 0.030" thick. With the doors now inserted, the vertical trim and the door threshold now protrude about a scale inch from the sheathing:

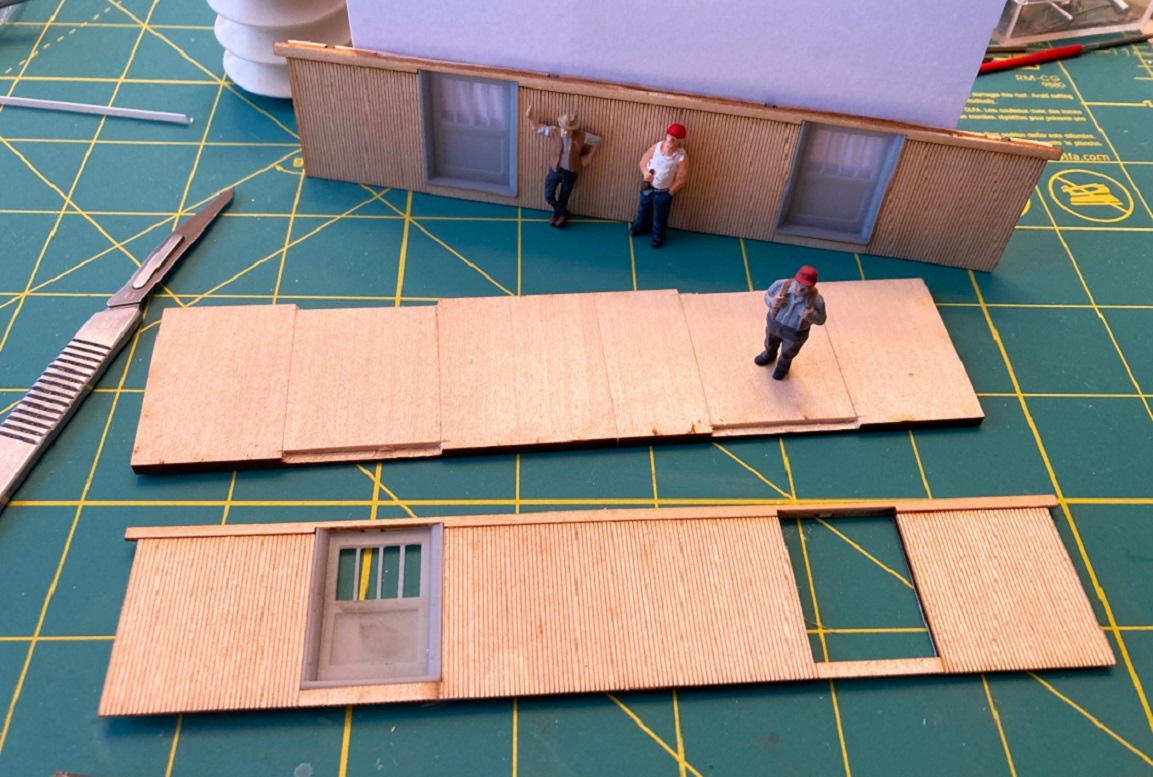

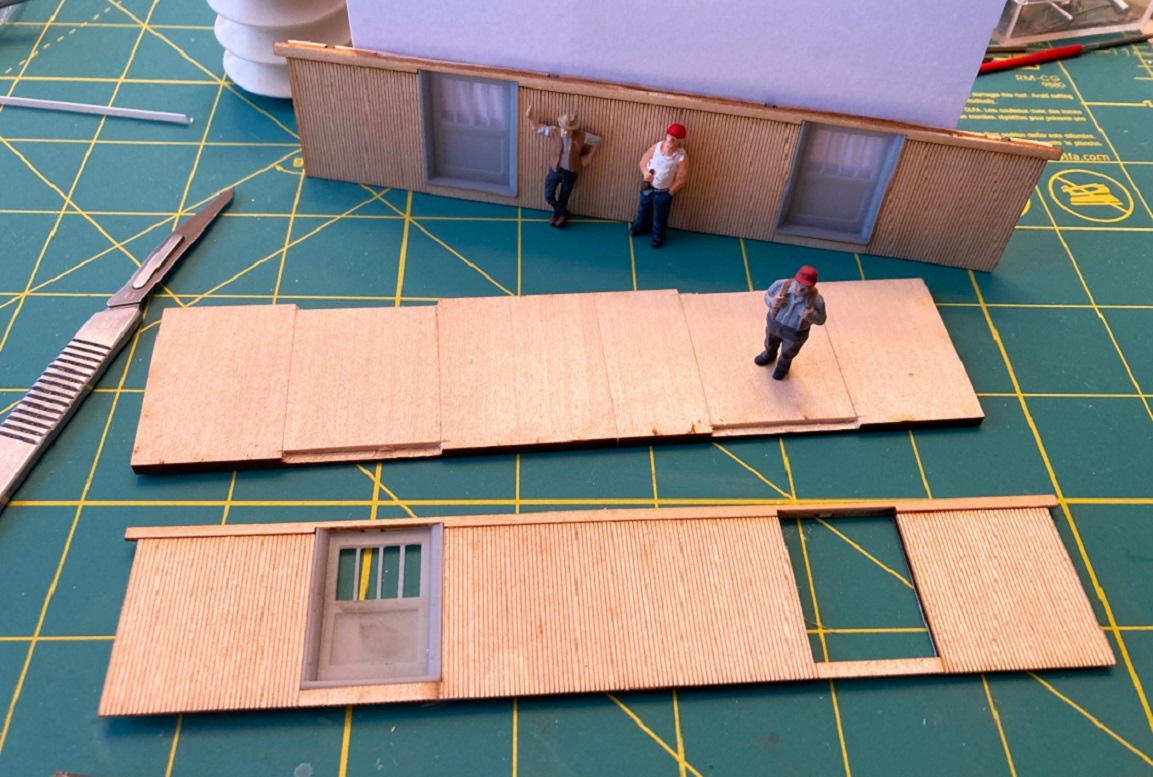

The other issue with the doors is an oversight on Bill's part. The top of the printed threshold of each door is meant to be even with the top of the floor. But the sides are supposed to be attached to the floor by gluing the strip of exposed sheathing to the side of the floor, while the bottom of the inner wall sits atop the floor and is glued. The printed door threshold intrudes into that space, so that the side sheathing will not be flush with the bottom of the floor. The solution was to use my razor saw and a new #11 scalpel blade to cut notches into the top of the floor to clear the doors (see title photo). Here are the two sides built up:

While the next step is attaching the sides to the floor, I decided to build up the ends next. The wood components are the same as the sides: Inner wall, thin outside sheathing, and top fascia board. Very clever Bill Meredith designed a one piece resin print of the end doors and end beams:

I'll keep you posted as I make progress. All you HO and O scale builders of baggage car 1, please post photos of your work and discuss any construction issues you encounter as well as your solutions. We C&S model builders now have baggage cars!

_________________

I'm stretched thin with several C&S projects abuilding at once. So I hired a crew of Keith's little people and flew them up from Denver to assist in this project. They're a rowdy bunch, but if one supplies them with plenty of S-scale beer they work hard and are friendly folks . . .

URL: http://c-sng-discussion-forum.254.s1.nabble.com/Leadville-Designs-Baggage-Express-1-in-C-Sn3-tp19129.html

I couldn't make it to the NNG convention, so I couldn't pick up my baggage car kits and trucks as did Keith and others. But the USPS left a package from Canada on my front porch yesterday. The cast brass trucks are neat, as Keith has reviewed, but my attention went straight to the baggage car kit. I was surprised and impressed that this Co-Op project turned out so well. Bill has produced a clever kit with an eclectic mixture of materials: Lase cut parts for the body, beautifully rendered resin prints for the major parts, brass and nickel-silver etchings for all the details, and the 5'-6" trucks to make it perfect. Of course, I started building the kit last evening.

The instructions say to begin by building up the roof. But as I suffer from clerestoryroofaphobia, I decided to build up the sides first to build up my confidence. The sides consist of an inner wall with door cut-outs, and outer very thin (1/32") layer, laser engraved with the sheathing, and a laser cut fascia board. The fascia is glued to the top of the inner wall first. I used Titebond III carpenters glue as it has a bit longer working time to line up things perfectly. I used my Fast Tracks assembly fixture as a thick straight-edge, to keep the top of the fascia board and the top of the inner wall flush.

The sheathing overlay is very fragile, I broke one of the horizontal planks (below the door), was able to repair it. When the overlays had been glued down, I let the wood components dry, under weights, overnight.

Today, I added the doors. I had dreaded building up 8 pieces of quarter round and trim to frame the doors, but Bill again surprised me with four beautifully detailed side doors as resin prints. When the door openings' sides and tops have been sanded flush, and the corners all squared up, the doors fit into the openings perfectly.

I did have two issues with the doors. Each door has two little side tabs, to allow the doors to be glued to the inner walls. These little tabs are a bit over 0.040" thick. When the doors are inserted into the sides, the vertical trim of the side quarter-round framing are pretty much flush with the side sheathing. IMHO, they and the door threshold should protrude from the sides a bit. So I used a 6" pillar file to carefully fill down the out side surface of each tab (the gluing surface) so that the tabs were only 0.030" thick. With the doors now inserted, the vertical trim and the door threshold now protrude about a scale inch from the sheathing:

The other issue with the doors is an oversight on Bill's part. The top of the printed threshold of each door is meant to be even with the top of the floor. But the sides are supposed to be attached to the floor by gluing the strip of exposed sheathing to the side of the floor, while the bottom of the inner wall sits atop the floor and is glued. The printed door threshold intrudes into that space, so that the side sheathing will not be flush with the bottom of the floor. The solution was to use my razor saw and a new #11 scalpel blade to cut notches into the top of the floor to clear the doors (see title photo). Here are the two sides built up:

While the next step is attaching the sides to the floor, I decided to build up the ends next. The wood components are the same as the sides: Inner wall, thin outside sheathing, and top fascia board. Very clever Bill Meredith designed a one piece resin print of the end doors and end beams:

I'll keep you posted as I make progress. All you HO and O scale builders of baggage car 1, please post photos of your work and discuss any construction issues you encounter as well as your solutions. We C&S model builders now have baggage cars!

_________________

I'm stretched thin with several C&S projects abuilding at once. So I hired a crew of Keith's little people and flew them up from Denver to assist in this project. They're a rowdy bunch, but if one supplies them with plenty of S-scale beer they work hard and are friendly folks . . .

Jim Courtney

Poulsbo, WA

Poulsbo, WA

| Free forum by Nabble | Edit this page |