Tongue and Groove Siding...

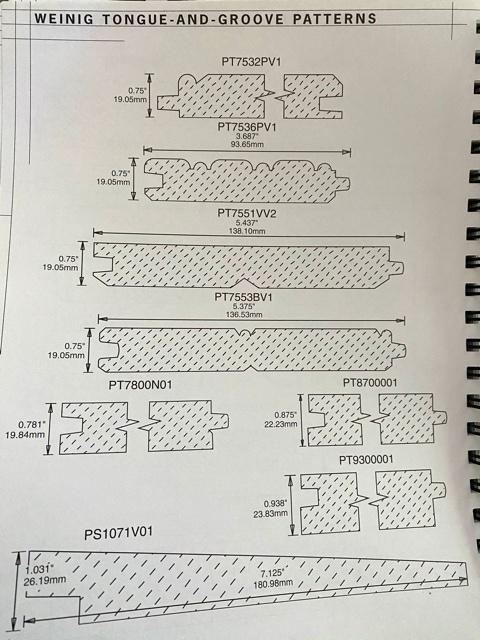

Looking at my Weinig Profile catalog this morning and here is a standard tongue and groove pattern that might be close to what we see on freight cars. This profile is still sold in home centers although no longer usually the full 3/4 thickness. There are literally hundreds of standard patterns for wood that are still available today. There were and are thousands of custom profiles that can be made quite easily too. Weinig makes 4 sided molders that do up to 12” wide boards. Their US headquarters is about 30 minutes from my home in Harrisburg, NC and I usually go to their yearly open house. I also know that Martin Machinery makes a single sided planer that can make profiles up to 24” wide. So if a restoration project needs a specific profile it is certainly fairly easy to do. Knives can be created from drawings or from a sample of the molding needed. Now you know some more of the story. Todd |

|

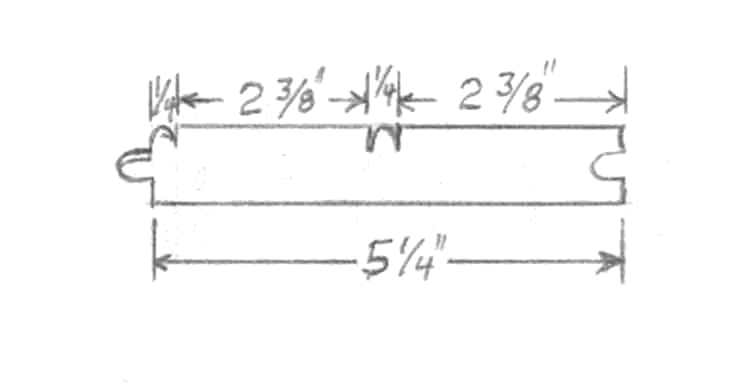

What I saw on the 27' car at St Elmo was similar but didn't have the groove on the back.

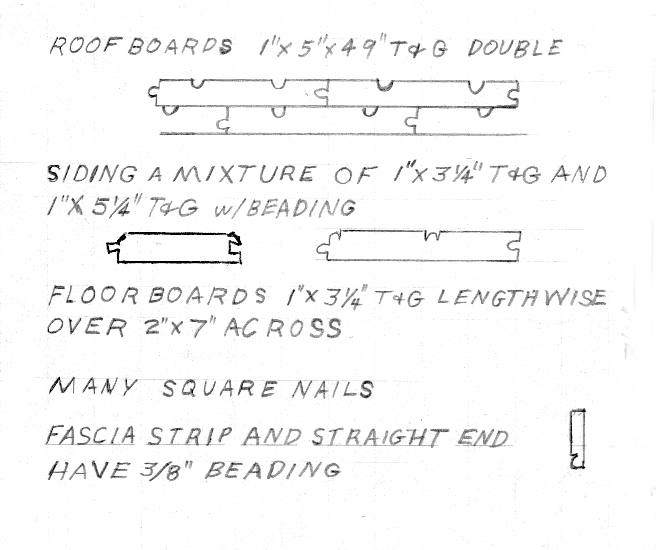

Here is a sketch of the board.  and siding on the 26' car.  Ken Martin |

Re: Tongue and Groove Siding...

|

Ken, thanks for sharing your information. I believe Mr Poole had some siding and roofing sketches in his MR article on building the outfit car. I do t recall the dimensions off the top of my head but they were probably the same as yours or similar.

I’m not sure what the reason would be for mixing wider and narrower boards other than wood movement with changes in relative humidity. But if the boards were pine and painted that would minimize wood movement for the most part too. These boards would not need the single V groove in the back as you noted. That is more of an interior use feature which offers 2 looks depending on which side is used. Simple to use a straight knife on the backside or no knife at all. I could make either of these board styles on my shaper with very common cutters too. It would take several passes and not be as efficient but certainly doable. Best, Todd |

Re: Tongue and Groove Siding...

|

In reply to this post by Ken Martin

The U channels in the roofing boards may have been there to help drain water off. But they also may have been there to stress relieve the boards from warping also.

Roof boards would be exposed to much harsher conditions than the siding. Rain and snow beating down and snow laying on them. Also the sun beating down on them and trying to draw moisture out the top side while the bottom side is going to be much slower to transfer moisture content. Best, Todd |

|

Todd,

I figured the car came in to the shop needing repair and had 5 1/4 boards and the shop only had 3 1/2 boards so they mixed them not wanting to resheath the whole car. According to the Car Cyc the top boards should be turned over and the grooves lined up forming a round hole and as the water seeped through the top joint and seeps sideways it hits the hole and drains out and not getting to the joint on the lower boards. In practice I don't think it worked too well. Ken |

|

In reply to this post by Todd A Ferguson

Good to know, Thank You.

|

Re: Tongue and Groove Siding...

|

In reply to this post by Ken Martin

Ken,

I agree. I don’t think the u grooves lined up would likely create a channel that would drain off water very well. I might create a couple samples and put them out on my deck at a roof like angle and do a test. Maybe when the price of lumber goes down...😳😎 Todd |

Re: Tongue and Groove Siding...

|

William Voss, in the classic Railway Car Construction of 1892, page 30:

"A satisfactory if not a perfect freight-car roof is one of the problems still to be solved, and considering the conditions of service involved, it is safe to say it will remain a problem for some time to come." He describes double board roofs briefly, one design having the groves facing up in both layers (as in Ken's drawing of the St Elmo car), and the other design having the upper board groves facing down and the lower board groves facing up to create a double size interior opening as the first design is "very apt to become clogged with cinders and dust." All sides of every board is painted in both applications. Two other designs were being experimented with at the time: single board with sheet metal covering (tin, turn or other metal) and sheet metal (or paper or composition) covered in wood on at least the outside, if not also the inside. I know that there have been lengthy talks about the wisdom of wood roofing designs by historians at the Society for the Preservation of Carter Railroad Resources, the Nevada State RR Museum and the California State RR Museum. What I've learned from these is that no design worked well for very long. No surprise.

Dave Eggleston

Seattle, WA |

«

Return to C&Sng Discussion Forum

|

1 view|%1 views

| Free forum by Nabble | Edit this page |